Three-liquid double-phase double-metal-ZTA ceramic composite material impact crusher plate hammer and manufacturing method thereof

A ceramic composite material, impact crusher technology, applied in the direction of manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problems of wear, low crushing efficiency, low service life, etc., achieve good crushing effect, meet frequent The effect of crushing impact and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments.

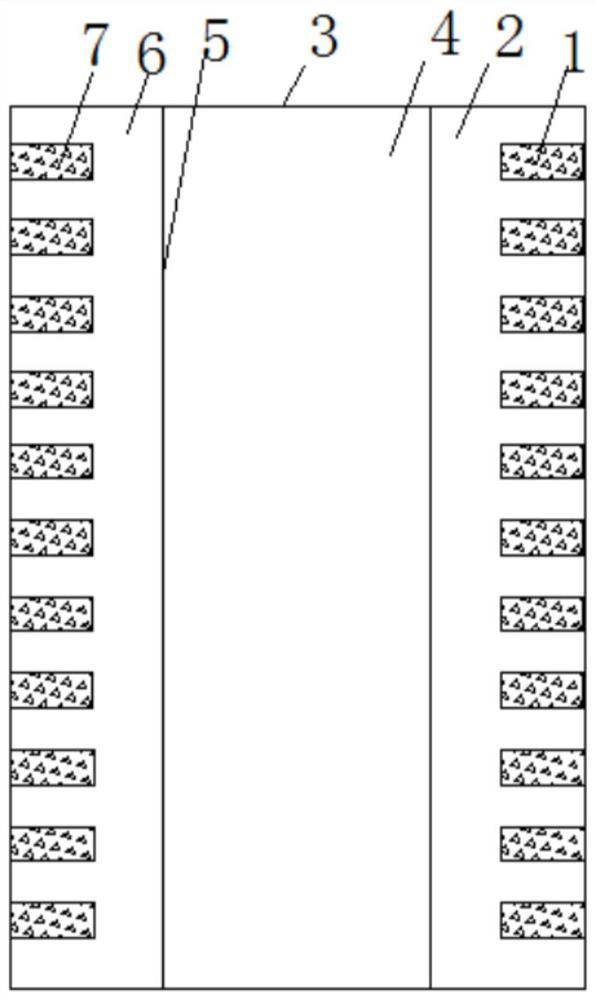

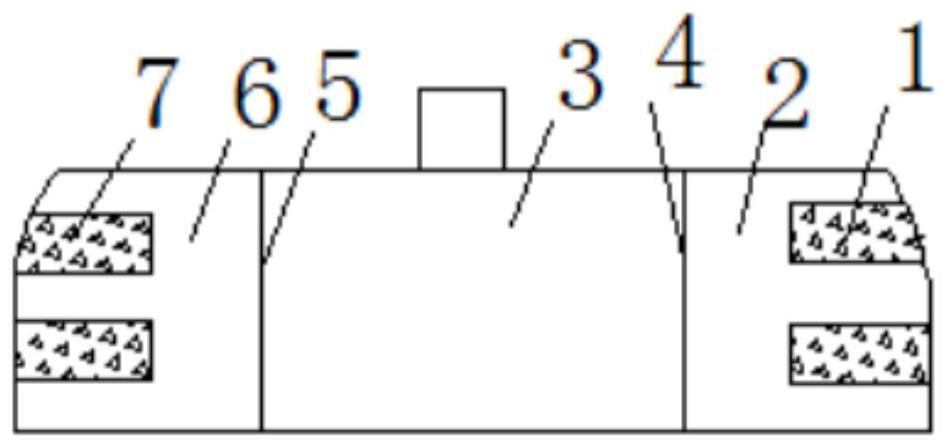

[0030] like Figures 1 to 2 , a three-liquid dual-phase bimetal-ZTA ceramic composite material impact crusher blow hammer of the present invention includes martensitic steel 3, high-chromium cast iron 2, 6 and high-chromium cast iron-ZTA composite cylinders 1, 7, The martensitic steel 3 is located in the middle, the high-chromium cast irons 2 and 6 are located on both sides of the martensitic steel 3, the high-chromium cast iron-ZTA composite cylinders 1 and 7 are multiple, and the high-chromium cast irons 2 and 6 located on both sides are the outermost , and evenly embedded in the outermost sides of high-chromium cast irons 2 and 6; the high-chromium cast iron-ZTA composite cylinders 1 and 7 are formed by melting high-chromium cast iron powder and bridging each other to evenly wrap the ZTA. The high-chromium cast iron-ZTA composite cylinders are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com