Medium-strength and high-plasticity Mg-Ce-Sm series plate and pre-stretching strengthening method thereof

A mg-ce-sm, high plasticity technology, applied in the field of magnesium alloy materials, can solve the problems of increasing the density and cost of magnesium alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

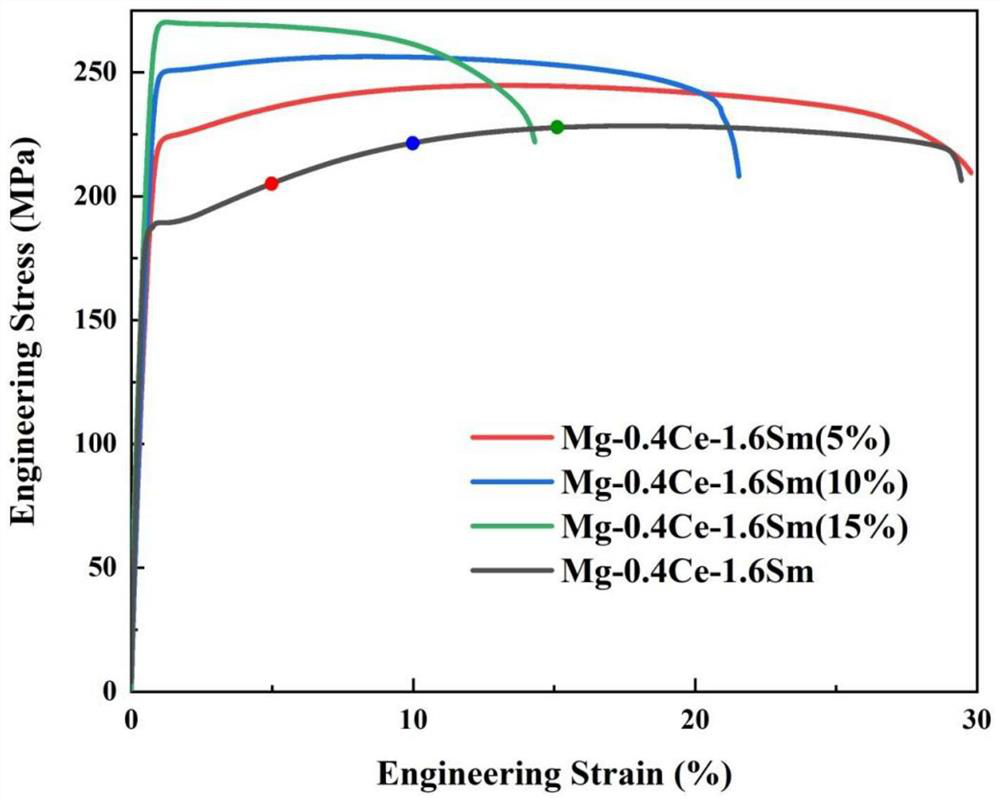

The Mg-0.4Ce-1.6Sm (0%) composition of the medium-strength and high-plastic deformation magnesium alloy sheet containing cerium-samarium element is: 0.4 wt.% Ce, 1.6 wt.% Sm, and the balance is Mg.

[0019] The preparation method of the high-strength wrought magnesium alloy containing cerium-samarium element of the present embodiment is:

(1) Weigh the following components according to mass percentage: 0.4 wt.% cerium, 1.6 wt.% samarium, the balance is magnesium, cerium is pure cerium or magnesium-cerium master alloy, and samarium is pure samarium or magnesium-samarium master alloy;

(2) Ingot smelting: under the protection of high-purity argon, heat industrial pure magnesium to 740~780 °C and melt the pure magnesium, add the alloying element Ce and Sm after melting, stir well, stir for 3~6 minutes, The temperature of the melt is controlled at 700-750 °C and allowed to stand for 10-20 minutes. After standing, the scum on the surface is removed, and the molten metal is cast...

Embodiment 2

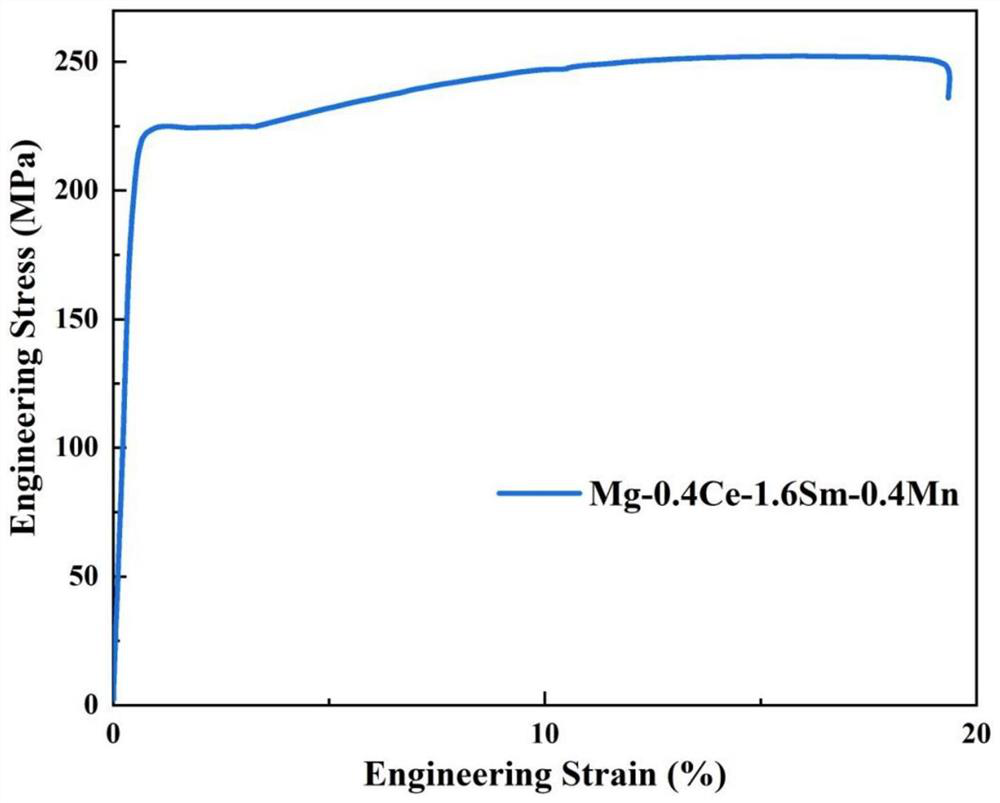

Medium-strength and high-plastic deformation magnesium alloy sheet Mg-0.4Ce-1.6Sm-0.4Mn (0%) containing cerium and samarium elements, the components are: 0.4wt.% Ce, 1.6wt.% Sm, 0.4wt. % Mn, balance Mg.

[0022] The preparation method of the high-strength wrought magnesium alloy containing cerium-samarium element of the present embodiment is:

(1) Weigh the following components by mass percentage: 0.4 wt.% cerium, 1.6 wt.% samarium, 0.4 wt.% manganese, the balance is magnesium, cerium is pure cerium or magnesium-cerium master alloy, and samarium is pure samarium or magnesium Samarium master alloy, manganese is pure manganese or magnesium manganese master alloy;

(2) Ingot smelting: Under the protection of high-purity argon, heat industrial pure magnesium to 740~780 °C and melt the pure magnesium, add alloying elements Ce, Sm, Mn to melt and stir well, stir for 3~6 The temperature of the melt is controlled at 700~750 °C for 10~20 minutes. After standing, the scum on the s...

Embodiment 3

Medium-strength and high-plastic deformation magnesium alloy sheet Mg-0.1Ce-3.0Sm-1.0Mn (0%) containing cerium-samarium element, the components are: 0.1 wt.% Ce, 3.0 wt.% Sm, 1.0 wt. % Manganese, balance Mg.

[0025] The preparation method of the high-strength wrought magnesium alloy containing cerium-samarium element of the present embodiment is:

(1) Weigh the following components by mass percentage: 0.1 wt.% cerium, 3.0 wt.% samarium, 1.0 wt.% manganese, the balance is magnesium, cerium is pure cerium or magnesium-cerium master alloy, samarium is pure samarium or magnesium Samarium master alloy, manganese is pure manganese or magnesium manganese master alloy;

(2) Ingot smelting: under the protection of high-purity argon, heat industrial pure magnesium to 740~780 °C and melt the pure magnesium, add the alloying element Ce and Sm after melting, stir well, stir for 3~6 minutes, The temperature of the melt is controlled at 700-750 °C and allowed to stand for 10-20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com