1500MPa-grade high-formability alloying hot galvanizing dual-phase steel and preparation method thereof

A formability and alloying technology, applied in heat treatment equipment, hot dipping process, heat treatment process control, etc., can solve the problems of insufficient ductility, influence on mechanical properties, influence on the structure of dual-phase steel, etc., to solve the problem of insufficient ductility. , The effect of solving the poor formability and improving the sensitivity of hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

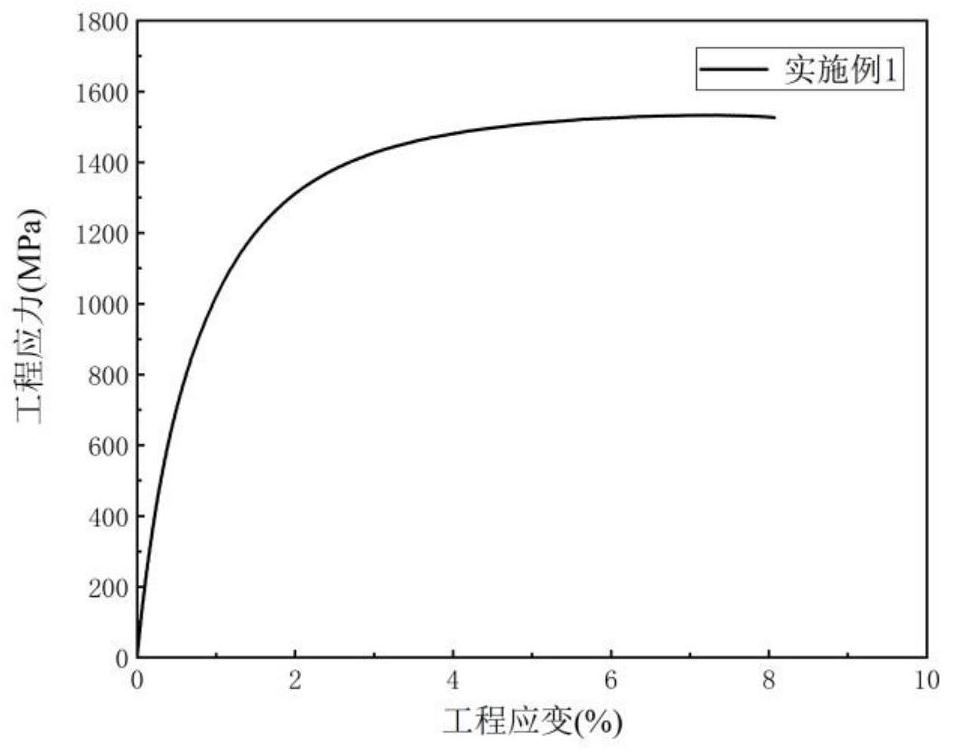

Image

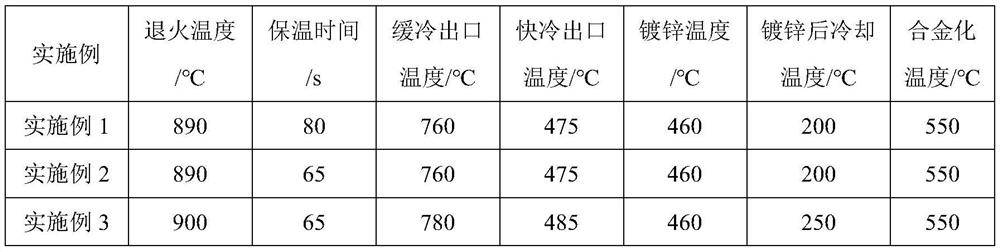

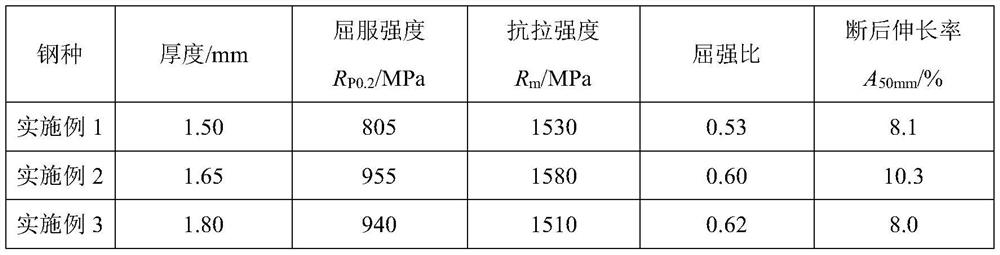

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the present invention, the present invention will be described more comprehensively and in detail below with reference to the embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

[0036]Unless otherwise defined, all technical terms used hereinafter have the same meaning as commonly understood by those skilled in the art. The technical terms used herein are only for the purpose of describing specific embodiments, and are not intended to limit the protection scope of the present invention.

[0037] Unless otherwise specified, various raw materials, reagents, instruments and equipment used in the present invention can be purchased from the market or can be prepared by existing methods.

[0038] Table 1 is a list of values of chemical components in each embodiment of the present invention.

[0039] The chemical composition of the embodiment of table 1

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com