Long-span maintenance hangar truss system and its L-shaped lattice columns

A truss system and lattice column technology, applied in the field of hangars, can solve problems such as the inability to intersperse and arrange narrow-body passenger aircraft maintenance stands, the vacant areas cannot be effectively used, and a large amount of manpower and material resources are invested, so as to shorten the load transmission line and improve Technical and economic indicators, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

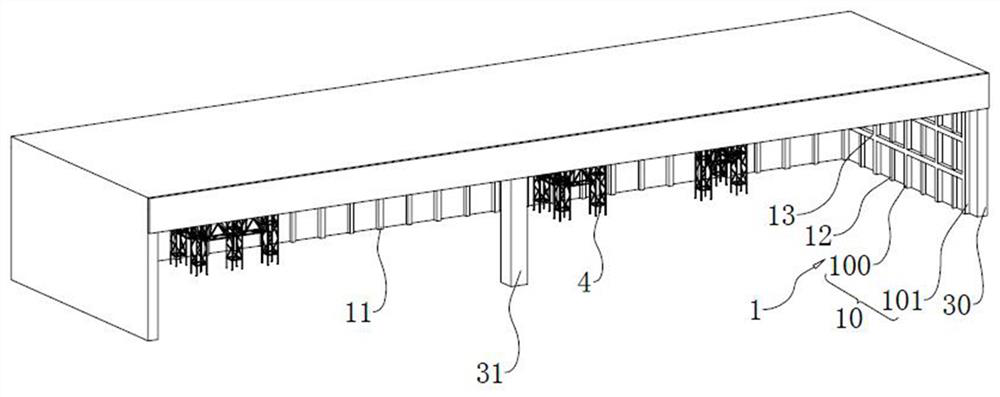

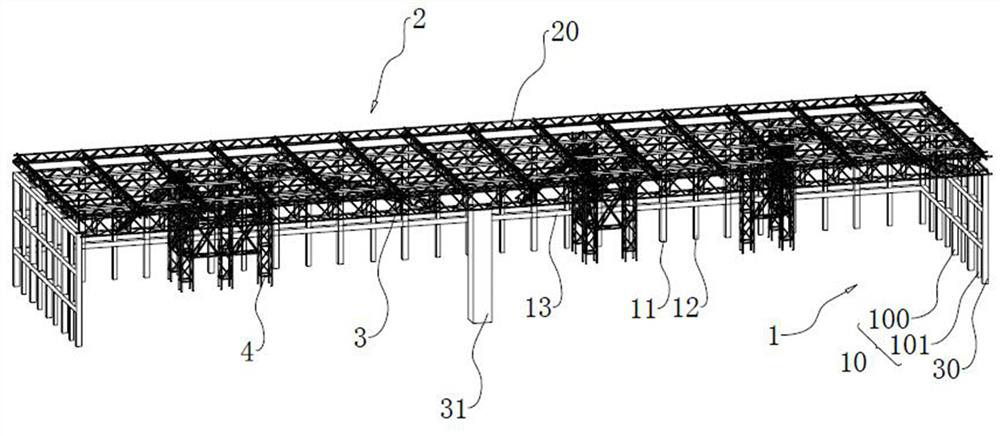

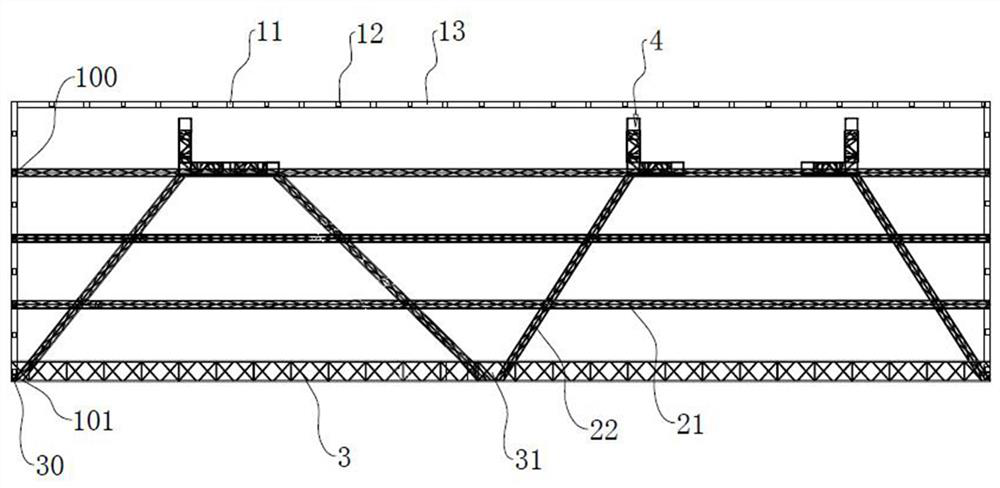

[0054] refer to figure 1 , Take a large-span maintenance hangar with a span of 405m, a width of 100m and an aspect ratio of more than 3 as an example. The large-span maintenance hangar truss system includes roof support column 1, roof steel structure 2, gate truss 3 and L Type lattice column 4. The side of the hangar facing the apron is open, and the open side is equipped with an electric sliding door that bears the lower load and guides upward. The steel structure of the roof in the hangar 2 suspension equipment systems, radiant heating, fire sprinkler and other electromechanical equipment systems and their related Matching maintenance walkway system.

[0055] refer to figure 1 and figure 2 The roof support column 1 includes a side wall support column 10, a rear gable support column 11, a wind resistance column 12 and a compression rod 13, which are arranged at intervals along the three sides of the hangar. The wind resistance column 12 is inserted between two adjacent s...

Embodiment 2

[0065] refer to Figure 7 The difference between this embodiment and Embodiment 1 is that, in order to slow down the vibration transmitted by the inclined truss 22 to the four-limb lattice columns 40, a connecting mechanism is also installed between the inclined truss 22 and the four-limb lattice columns 40. The connecting mechanism It includes a support plate 5 , a horizontal insertion cylinder 6 , a turntable 7 and a vertical insertion cylinder 8 .

[0066] There are four guide cylinders 50 on the top of the support plate 5 and four horizontal insertion cylinders 6. The guide cylinders 50 have a cylindrical structure with openings at both ends, and the horizontal insertion cylinder 6 is a cylinder structure with one end open. The open end of the guide cylinder 50 faces the guide cylinder 50 , and a reinforcing rod 51 is welded between the adjacent two guide cylinders 50 , the two adjacent horizontal insertion cylinders 6 , and the adjacent guide cylinders 50 and the horizont...

Embodiment 3

[0075] refer to Figure 11 and Figure 12 The difference between this embodiment and Embodiment 2 is that a hole plugging device 9 is provided in the slurry storage cavity 620, and the hole plugging device 9 includes a main cylinder 90, which is coaxially arranged with the horizontal insertion cylinder 6, A secondary cylinder 91 is vertically fixed at the end of the main cylinder 90 away from the limiting cylinder 60 . The secondary cylinder 91 includes five sub-cylinders and is in the shape of a five-pointed star. The connection point between the main cylinder 90 and the secondary cylinder 91 is located in the secondary cylinder. At the center of the cylinder 91 , a support rod 910 for supporting the secondary cylinder 91 is fixed between the side of the secondary cylinder 91 away from the main cylinder 90 and the closed end of the horizontal insertion cylinder 6 . A plugging cylinder 92 is slidably and sealedly connected in each auxiliary cylinder 91 .

[0076] Lubricating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com