Damper fault detection method and system based on intelligent pattern recognition

A technology for pattern recognition and fault detection, applied in the field of artificial intelligence, can solve problems such as low detection efficiency, achieve high detection efficiency, reduce the probability of missed detection and false detection, and avoid subjectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

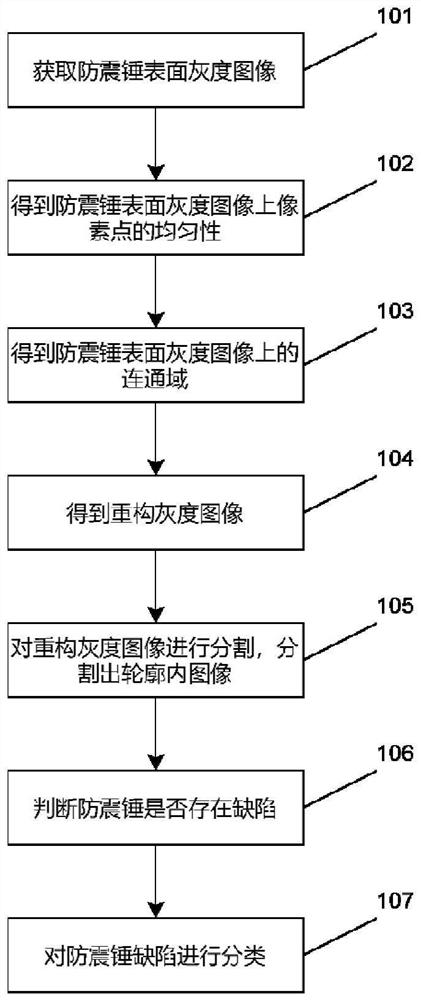

[0042] An embodiment of an anti-vibration hammer fault detection method based on intelligent graphic recognition of the present invention, such as figure 1 shown, including:

[0043] 101. Acquire a grayscale image of the surface of the anti-vibration hammer.

[0044] 102. Perform sliding window processing on the grayscale image of the shockproof hammer surface, and calculate the uniformity of the center pixel of the sliding window according to the grayscale value of each pixel in the sliding window and the grayscale mean of all pixels, and obtain the grayscale of the shockproof hammer surface. The uniformity of each pixel on the image.

[0045] Calculate the uniformity of the pixel points in the sliding window by using the gray value of the pixel point in each sliding window, and use the uniformity value as the uniformity of the center pixel point. Through this method, each pixel on the grayscale image of the shock-proof hammer surface is obtained. point uniformity.

[0046...

Embodiment 2

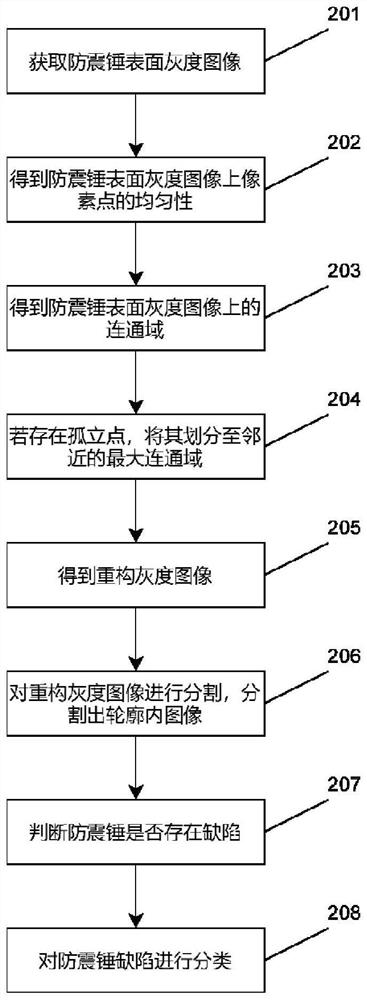

[0054] An embodiment of an anti-vibration hammer fault detection method based on intelligent graphic recognition of the present invention, such as figure 2 shown, including:

[0055] The scenarios for this embodiment are as follows: first, a camera is set up, a light source is arranged, a grayscale image of the surface of the anti-vibration hammer product is collected, and the obtained grayscale image of the surface of the anti-vibration hammer product is processed to obtain a uniform target area. The gray gradient is used for reconstruction, the watershed algorithm is used to segment the reconstructed image, and the image recognition technology is used to process the segmentation results to achieve the purpose of classifying defect types.

[0056] 201. Acquire a grayscale image of the surface of the anti-vibration hammer.

[0057] In this embodiment, it is necessary to identify the fault of the anti-vibration hammer in the production process, and the surface image of the an...

Embodiment 3

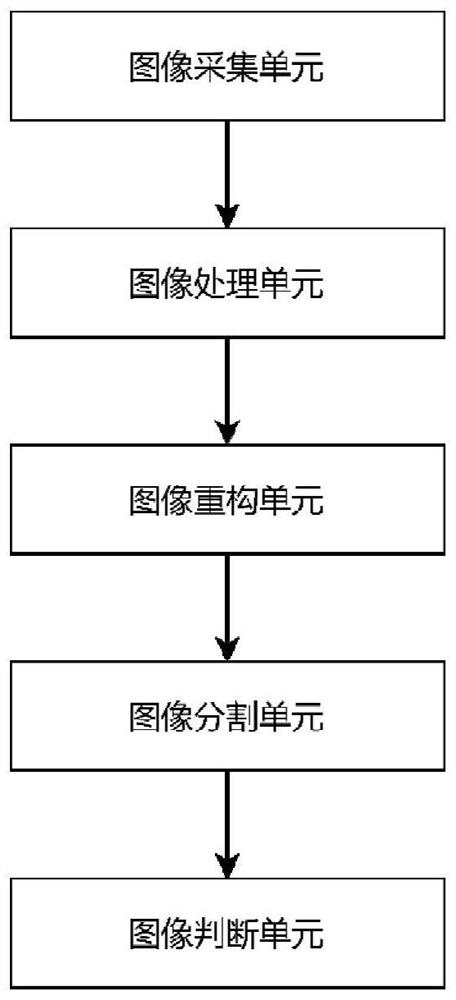

[0093] An embodiment of an anti-vibration hammer fault detection system based on intelligent graphic recognition of the present invention, such as image 3 shown, including:

[0094] The image acquisition unit obtains the grayscale image of the surface of the shockproof hammer;

[0095] Set the camera just above the anti-vibration hammer, place the anti-vibration hammer on the white background, collect the image of the anti-vibration hammer, segment the obtained image to obtain the image of the anti-vibration hammer without the background, and then pass the image of the anti-vibration hammer without the background. Obtain a grayscale image of the shock hammer surface.

[0096] The image processing unit performs sliding window processing on the grayscale image of the anti-vibration hammer surface, and calculates the uniformity of the center pixel of the sliding window according to the gray value of each pixel in the sliding window and the average gray value of all pixels to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com