Image sensor and forming method thereof

An image sensor and patterning technology, applied in semiconductor devices, electric solid state devices, radiation control devices, etc., to achieve the effect of improving upper defects, improving performance, and reducing white noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As described in the background art, there are still many problems in the formation process of the prior art CMOS image sensor. The following will be described in detail with reference to the accompanying drawings.

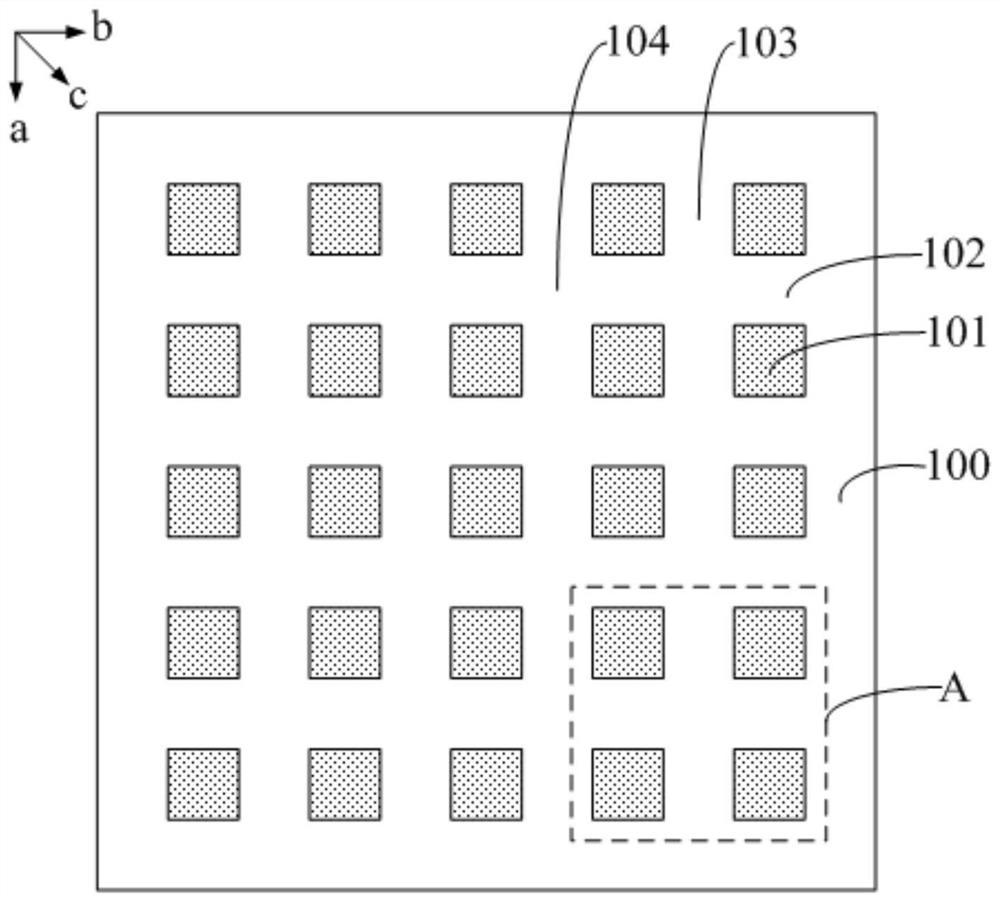

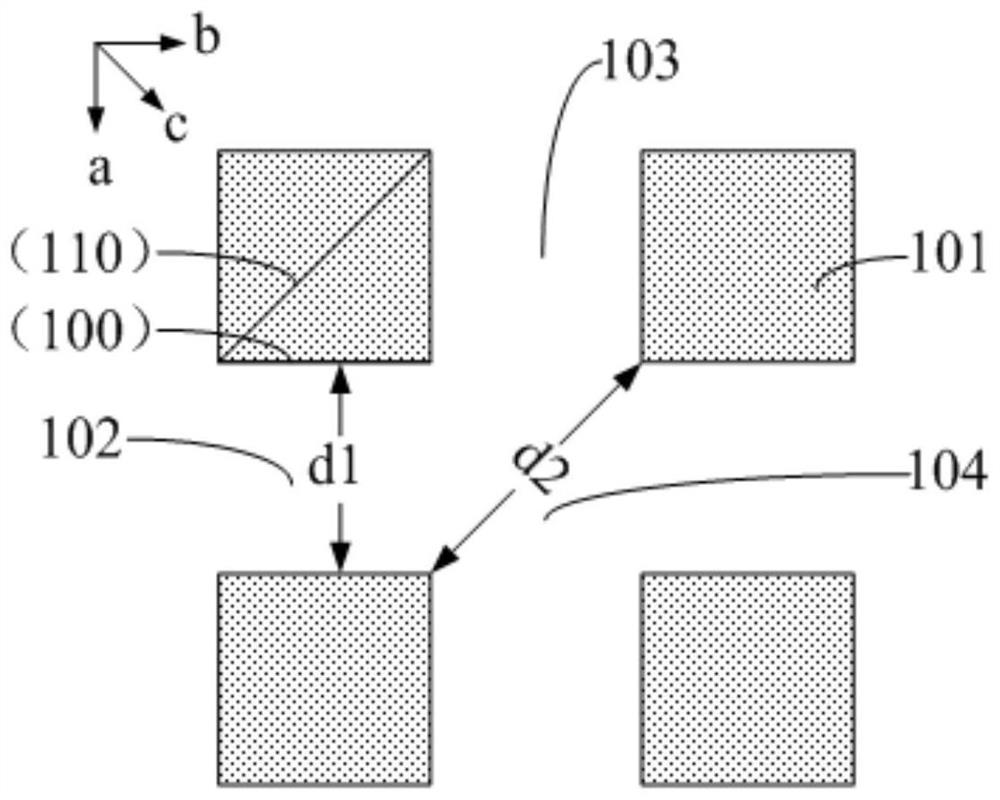

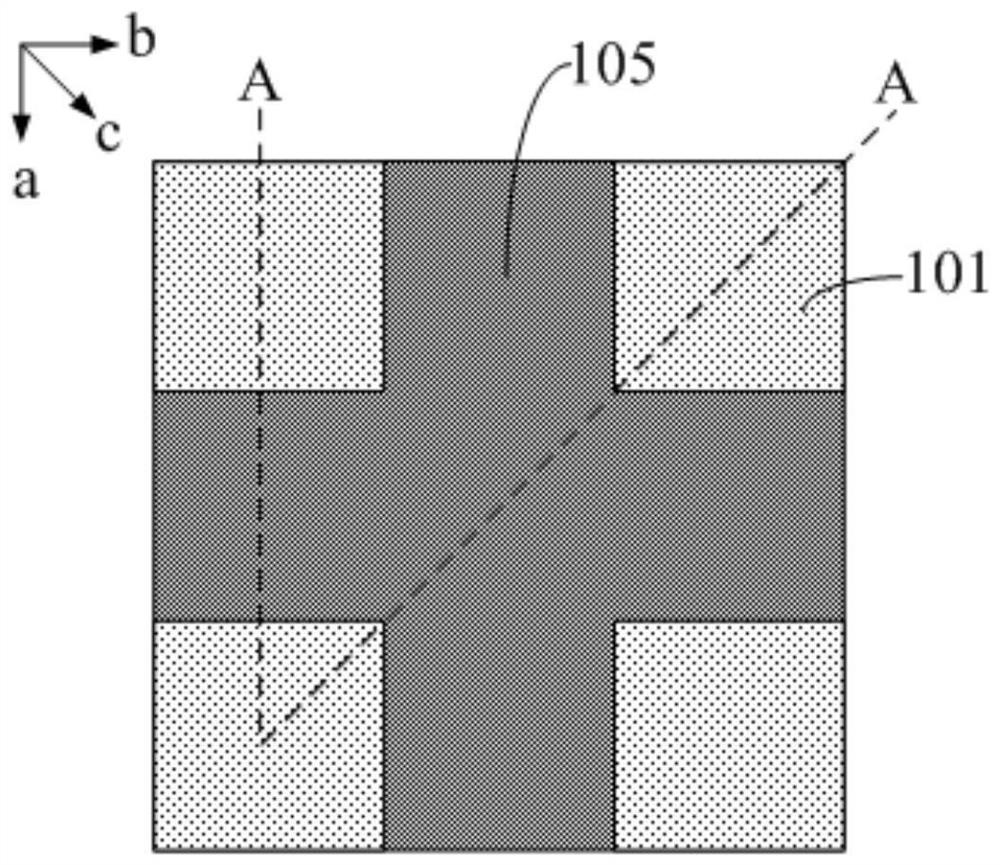

[0033] Figure 1 to Figure 4 It is a schematic structural diagram of each step of a method for forming an image sensor; Figure 5 It is a schematic diagram of the formation process of the doped epitaxial layer of the image sensor.

[0034] Please refer to figure 1 and figure 2 , figure 2 Yes figure 1 In the enlarged schematic diagram of the structure of part A, a substrate 100 is provided, and the substrate 100 has first ions; the substrate 100 is patterned to form a plurality of columnar structures 101 distributed in an array, which are arranged in a row along the first direction a There are first deep trenches 102 between the columnar structures 101 of the cloth, second deep trenches 103 are arranged between the columnar structures 101 arranged al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com