Quantum dot light emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of device efficiency that needs to be improved, achieve balance improvement, improve luminous efficiency, and improve hole transport efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

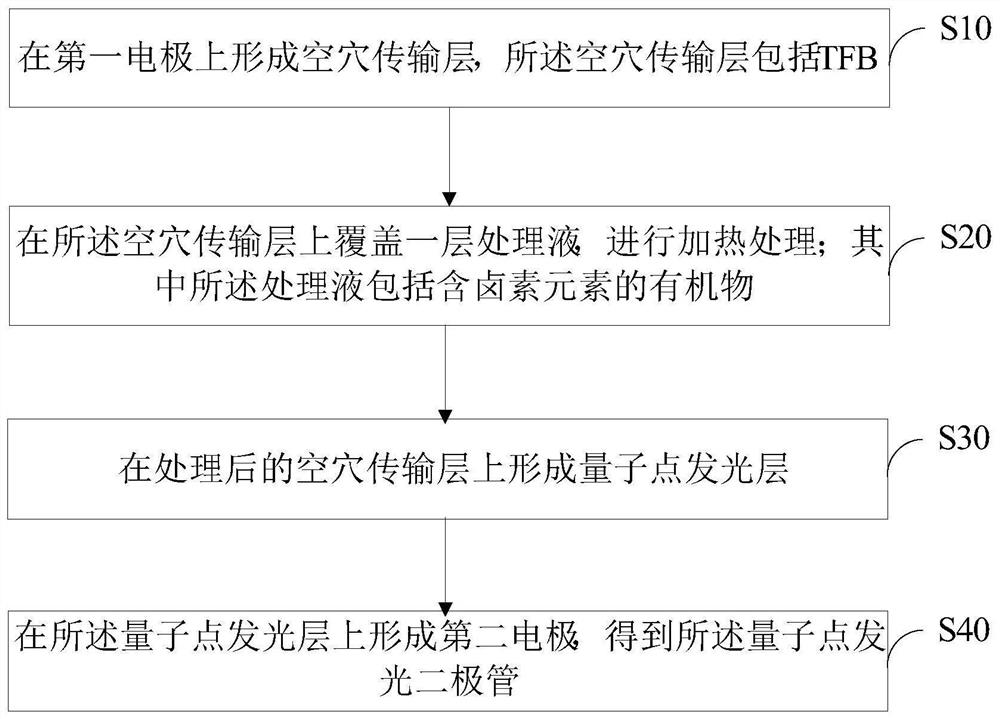

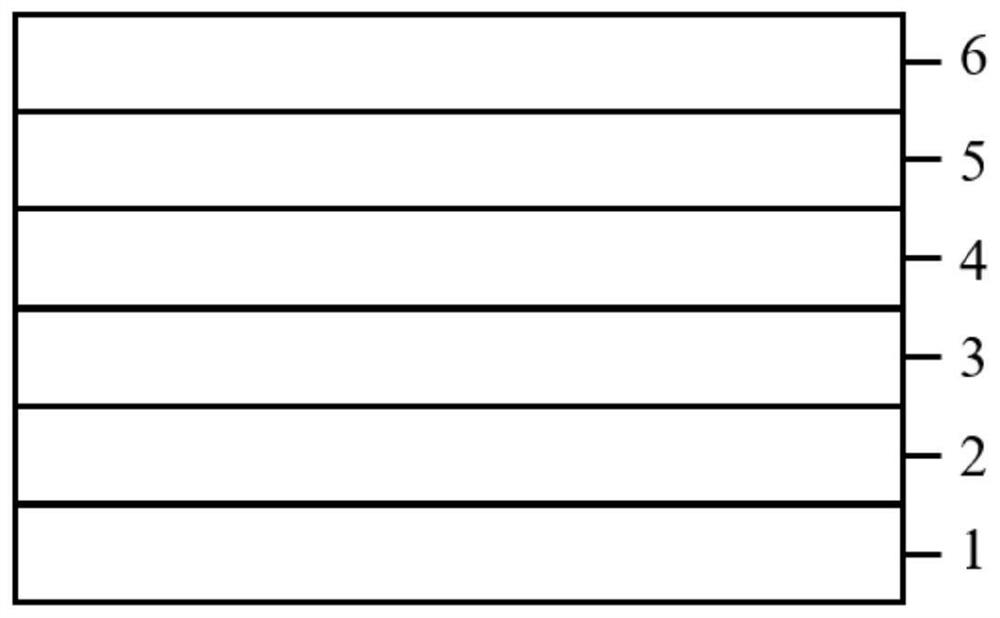

[0051] Evaporate ITO on the substrate as the first electrode, the thickness of ITO is 40nm, then UVO (ultraviolet light ozone) cleaning for 15min, cleaning the surface while improving the surface wettability, and improve the work function of ITO;

[0052] A layer of PEDOT:PSS was spin-coated on ITO as a hole injection layer. The spin-coating speed was 4000 rpm for 40 s, and then annealed at 150 °C for 15 min. The whole step was carried out in air;

[0053] A layer of TFB was spin-coated on the hole injection layer as a hole transport layer. The TFB was dissolved in chlorobenzene at a concentration of 8 mg / ml. 20min, the whole step is carried out in the glove box;

[0054] Treat the surface of the TFB layer, drop an ethanol solution of trifluoromethoxybenzene on the surface of the TFB layer, the concentration of trifluoromethoxybenzene is 1 mg / ml, and then heat at 120 ° C for 10 min;

[0055] The quantum dot light-emitting layer was spin-coated on the hole transport layer, the...

Embodiment 2

[0059] Evaporate ITO on the substrate as the first electrode, the thickness of ITO is 40nm, then UVO (ultraviolet light ozone) cleaning for 15min, cleaning the surface while improving the surface wettability, and improve the work function of ITO;

[0060] A layer of PEDOT:PSS was spin-coated on ITO as a hole injection layer. The spin-coating speed was 4000 rpm for 40 s, and then annealed at 150 °C for 15 min. The whole step was carried out in air;

[0061] A layer of TFB was spin-coated on the hole injection layer as a hole transport layer. The TFB was dissolved in chlorobenzene at a concentration of 8 mg / ml. 20min, the whole step is carried out in the glove box;

[0062] Treat the surface of the TFB layer, drop a trichloromethylphenol ethanol solution on the surface of the TFB layer, the solution concentration is 0.5 mg / ml, and then heat at 100 ° C for 20 min;

[0063] The quantum dot light-emitting layer was spin-coated on the hole transport layer, the quantum dots were dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com