Process for preparing foam control composition in particle or powder form

A technology of foam control and foam control agent, which is applied in detergent composition, organic cleaning composition, separation method, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0095] In order to facilitate a better understanding of the present invention, the following examples of certain aspects of some embodiments are given. The following examples should in no way be construed to limit or define the scope of the present invention.

Embodiment 1

[0098] Composition 1 is obtained by mixing components (I) and (II):

[0099] (1) Polymer A, 70 g calcium lignosulfonate liquid (Flambeau River Papers)

[0100] (II) 30 grams of foam control agent concentrate, containing:

[0101] a) 40% Silcolapse TM Mixture of 825 & 500, 75:25 wt% (Elkem Silicones),

[0102] b) 25% 5803 (Evonik), and

[0103] c) 35% L-101 (BASF).

[0104] The compositions are mixed together using a high speed mixer. After drying using a conventional rotary evaporator and a 105°C oil bath for about 2 hours, a brittle brown material was produced that was easily ground to a dry powder with a mortar and pestle. The yield of this preparation was 64 grams. On a dry weight basis, this formulation contained 51% antifoam concentrate and contained 19% silicone antifoam compound.

Embodiment 2

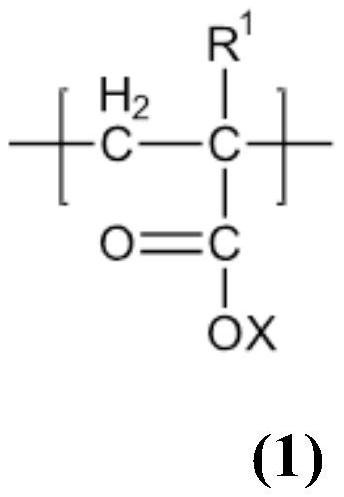

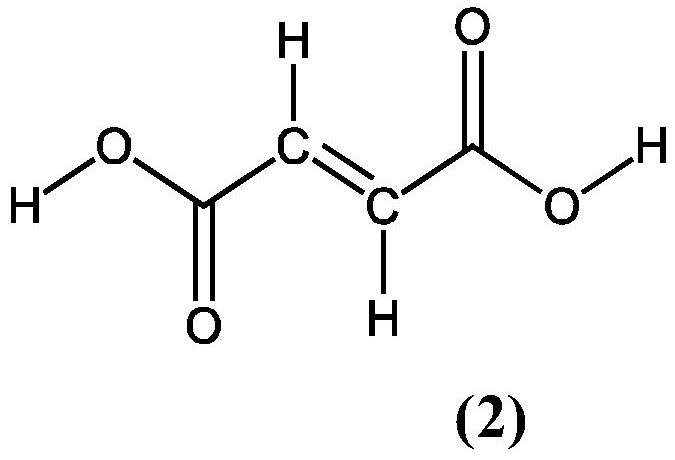

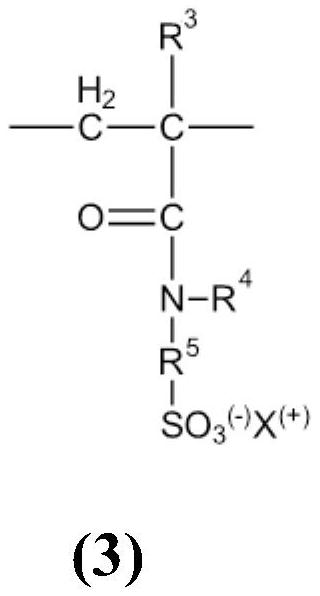

[0106] Polymer A: AR-540 Copolymer of acrylic & sulfonated monomers, (45% solids). This predominantly acidic (pH 3-4) copolymer should be salted in situ.

[0107] Composition 2: (in situ salting of the polymer by aqueous triethanolamine solution), obtained by mixing components (I) and (II):

[0108] (1) 70 grams of an aqueous dispersion, comprising:

[0109] a) 50g Aquatreat AR-540 pH 3-4 (Nouryon)

[0110] b) 10 g of triethanolamine (79% in water)

[0111] c) 5 grams of magnesium sulfate (PQ)

[0112] d) 5 grams of dioctyl sulfosuccinate (Dow GR-5M)

[0113] (II) 30 grams of defoamer concentrate

[0114] a) 15g Silcolapse TM 500 (Elkem Silicones),

[0115] b) 3 grams 5803(Evonik)

[0116] c) 12 g polypropylene glycol (PPG) 2000 (Vantage)

[0117] The compositions are mixed together using a high speed mixer. After drying using a conventional rotary evaporator and a 105°C oil bath for about 2 hours, this produced a slightly clumpy pale yellow material that was easi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com