A kind of modified water reducing agent and preparation method thereof

A water-reducing agent and modification technology, applied in the field of modified water-reducing agent and its preparation, can solve the problems of reduced concrete strength, unsuitable for winter construction, concrete not hardening, etc. Good adaptability of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

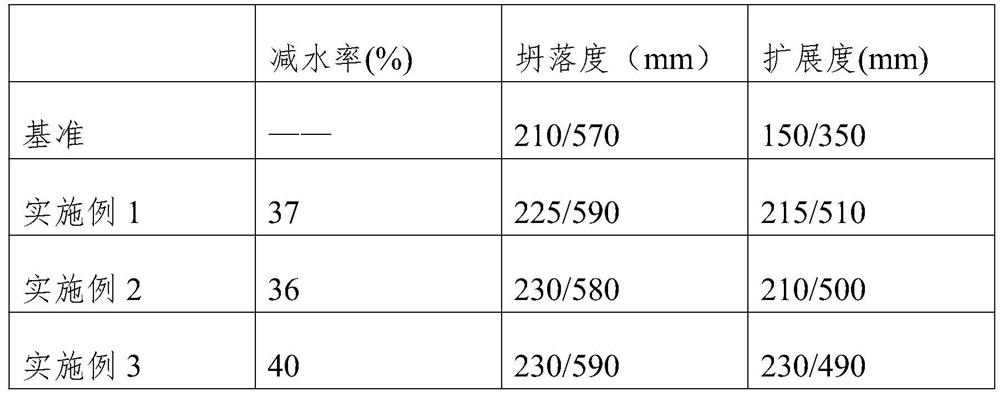

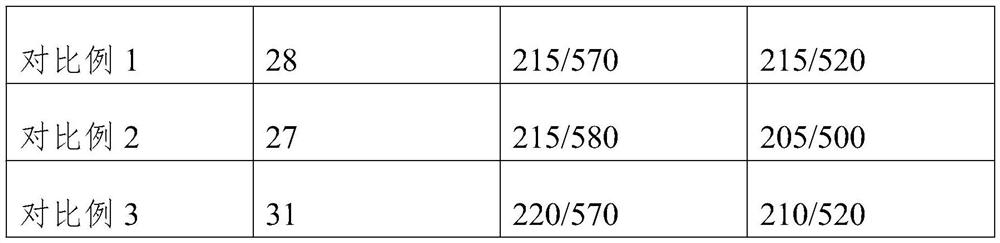

Examples

Embodiment 1

[0030] A modified water reducer, raw materials include: amino acid 2kg, polycarboxylate water reducer 12kg, melamine 4kg, gluconate 8kg, sulfonated black liquor 7kg;

[0031] Described sulfonated black liquor, its preparation method comprises the steps:

[0032] (1) Take papermaking black liquor and diatomaceous earth and mix evenly at a mass ratio of 1:0.03, stir for 50 minutes at a temperature of 40°C, then cool to room temperature, filter to get the filter residue;

[0033] (2) Add 95% citric acid solution of 0.2 times the quality of the filter residue and 80% sulfuric acid solution of 0.01 times the quality of the filter residue to the filter residue, stir for 30 min at a temperature of 95° C., then cool to 78° C., add 30% citric acid solution of 0.2 times the quality of the filter residue % sulfonating agent stirred for 30min, lowered to normal temperature to obtain sulfonated black liquor;

[0034] The sulfonating agent is sodium methylsulfonate;

[0035] The preparati...

Embodiment 2

[0040] A modified water reducer, raw materials include: amino acid 10kg, polycarboxylate water reducer 18kg, melamine 9kg, gluconate 15kg, sulfonated black liquor 20kg;

[0041] Described sulfonated black liquor, its preparation method comprises the steps:

[0042] (1) Take papermaking black liquor and diatomaceous earth and mix evenly at a mass ratio of 1:0.05, stir for 60 minutes at a temperature of 50°C, then cool to room temperature, filter to get the filter residue;

[0043] (2) Add 98% citric acid solution of 0.4 times the quality of the filter residue and 80-85% sulfuric acid solution of 0.03 times the quality of the filter residue to the filter residue, stir at a temperature of 98°C for 35min, then cool down to 85°C, and add 0.4 times the weight of the filter residue 50% of the sulfonating agent was stirred for 35 minutes and cooled to normal temperature to obtain sulfonated black liquor;

[0044] The sulfonating agent is a mixture of sodium isethionate and sodium hyd...

Embodiment 3

[0050] A modified water reducer, raw materials include: amino acid 6kg, polycarboxylate water reducer 15kg, melamine 6kg, gluconate 11kg, sulfonated black liquor 14kg;

[0051] Described sulfonated black liquor, its preparation method comprises the steps:

[0052] (1) Take papermaking black liquor and diatomaceous earth and mix evenly at a mass ratio of 1:0.04, stir for 55 minutes at a temperature of 45°C, then cool to room temperature, and filter to obtain the filter residue;

[0053] (2) Add 96% citric acid solution with 0.3 times the quality of filter residue and 82% sulfuric acid solution with 0.02 times the quality of filter residue to the filter residue, stir for 32min at a temperature of 97°C, then cool to 82°C, add 30% citric acid solution with 0.3 times the quality of filter residue Stir with -50% sulfonating agent for 32 minutes and cool down to normal temperature to obtain sulfonated black liquor;

[0054]The sulfonating agent is a mixture of sodium hydroxymethanes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com