Furanone preparation system and preparation method

A preparation system and technology of furanone, which is applied in the preparation system and field of furanone, can solve the problems of low yield and difficult industrial production and operation of raw materials, achieve cheap raw materials, reduce washing times and waste water discharge, and reduce risks The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

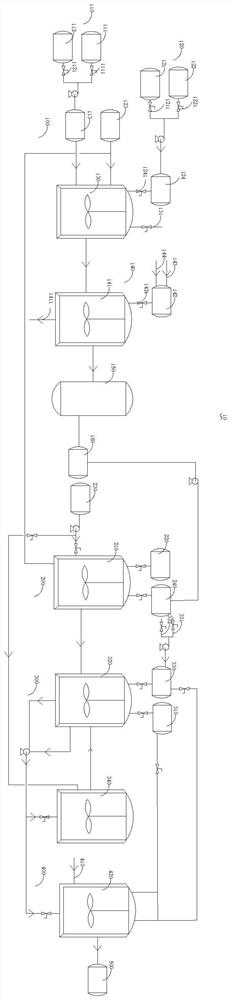

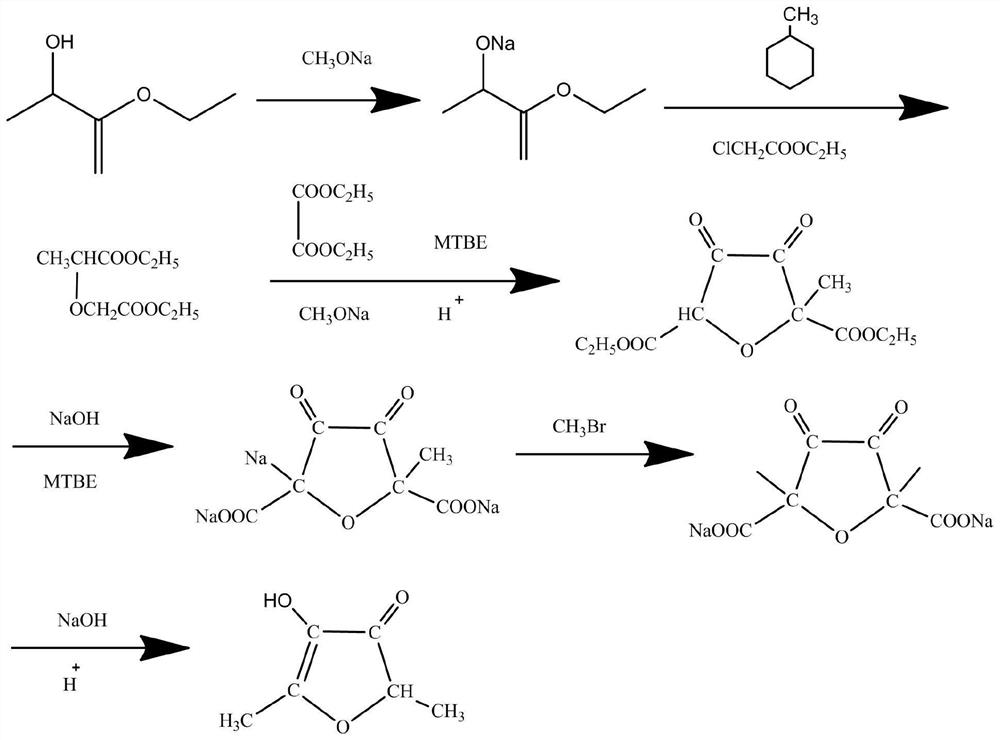

[0051] A preparation method of furanone, utilizing the above-mentioned furanone preparation system 10 to prepare, comprises the following steps:

[0052] S1: add the mixture material 250kg-270kg in the mixture storage tank 111 into the first reactor 130, then add the sodium methoxide 170kg-180kg into the first reactor 130, at the first predetermined temperature 110 ℃-115 Under ℃, stir intermittently until the solid sodium methoxide cannot be seen, then cool down to the second predetermined temperature of 85°C-90°C, add 1385.60kg of toluene in the toluene storage tank 112, and then cool down to the third predetermined temperature of 25°C-35°C. ℃, then dropwise add 570kg-580kg of ethyl lactate in the ethyl lactate storage tank 121, the dropping rate is 10kg / min, and the first predetermined reaction time is 0.8h-1.2h) to generate ethyl lactate sodium salt; then dropwise add The ethyl chloroacetate 415kg-425kg in the ethyl chloroacetate storage tank 122, the dropping rate is 10kg / ...

Embodiment

[0067] Add 300L of the mixture in the mixture storage tank 111 to the first reactor 130, then add 176kg of sodium methoxide to the first reactor 130, and at 110°C-115°C, stir intermittently until no longer visible. to sodium methoxide solid, then be cooled to 85 ℃-90 ℃, then add toluene 1385.60kg in the toluene storage tank 112, then be cooled to 25 ℃-35 ℃, then dropwise add the ethyl lactate storage tank 121 with 10kg / min. 578kg of ethyl lactate was reacted for 1h to generate ethyl lactate sodium salt; then 420kg of ethyl chloroacetate in the ethyl chloroacetate storage tank 122 was added dropwise at 10kg / min, and after the dropwise addition was completed, the temperature was raised to 70°C-75°C , react for 2h to generate diethyl α-methyl diglycolate, wash and distill with water after the reaction, to obtain the product diethyl α-methyl diglycolate; at 30 ℃-38 ℃, the The material of the first reaction kettle 130 was added to the washing kettle 141, and then the mixture of 750...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com