Wood veneer coating process for pre-coating paint

A veneer and coating technology, which is applied to wood processing equipment, coatings, primers, etc., can solve the problems of veneer fiber breakage, long drying time, veneer cracking, etc., to promote penetration, reduce production difficulty, and prevent veneer cracking Effect

Active Publication Date: 2022-06-10

小森新材料科技有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Combination veneer is also called coated veneer. The existing veneer is formed by veneer and non-woven fabric. However, most of the veneer on the market has not been sprayed with paint. After the glue with non-woven fabric is completed, UV is started on the lines. or PU coating, and the veneer fiber is easy to break, therefore, the veneer is prone to cracking and breaking during the coating and pasting process, so it cannot be used

In addition, in the subsequent painting process, it is necessary to repair the cracks on the surface of the veneer, which requires multiple processing, which seriously reduces the efficiency, and consumes a lot of energy and takes a long time to dry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

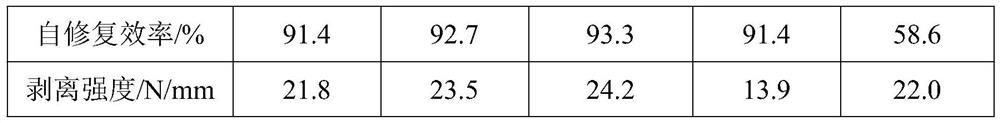

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

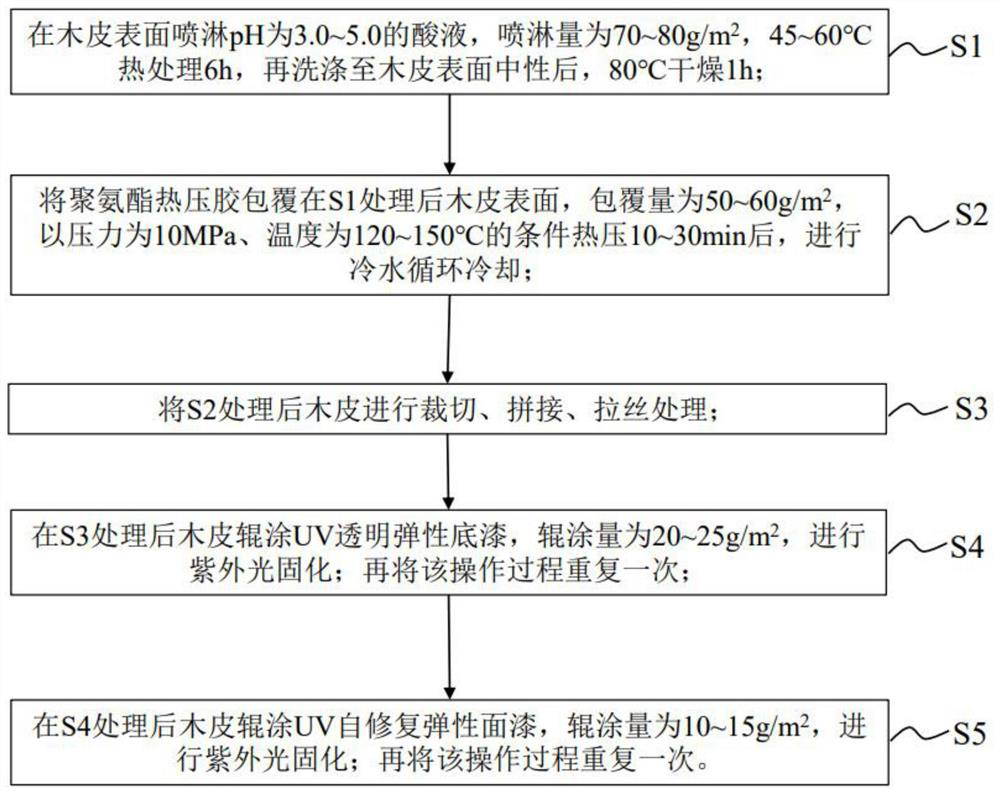

The invention discloses a wood veneer coating process for pre-coating paint. The wood veneer coating process comprises the following steps that S1, wood veneers are treated with acid liquor; s2, the surface of the wood veneer treated in the step S1 is coated with polyurethane hot-pressing glue, the coating amount is 50-60 g / m < 2 >, hot pressing is conducted for 10-30 min under the conditions that the pressure is 10 MPa and the temperature is 120-150 DEG C, and then cold water circulation cooling is conducted; s3, the wood veneers treated in the S2 are subjected to cutting, splicing and wire drawing treatment; s4, UV transparent elastic primer is coated on the wood roller treated in the step S3, the roller coating amount is 20-25 g / m < 2 >, and ultraviolet curing is carried out; the operation process is repeated once; s5, UV self-repairing elastic finish paint is coated on the wood roller treated in the step S4, the roller coating amount is 10-15 g / m < 2 >, and ultraviolet curing is carried out; and the operation process is repeated once. The polyurethane hot-pressing adhesive is adopted to replace traditional non-woven fabric wrapping the back face of the wood veneer, the wood veneer and the polyurethane hot-pressing adhesive are subjected to hot pressing through the hot-pressing equipment, the hot-pressing adhesive partially permeates into the wood veneer, the flexibility of the wood veneer is improved, the wood veneer is prevented from cracking, and a sufficient elastic protection layer is formed.

Description

A pre-painted cladding veneer process technical field The invention belongs to the field of veneer surface treatment, be specifically related to a kind of cladding veneer technique of prepainted paint. Background technique Veneer is a kind of common decorative material, mainly used in the production of furniture, decorative veneer, wooden door, floor fabric etc. Field, wood flake-like material produced by the peeling or sawing method, the thickness of which is usually between 0.4‑1.0mm, and can be divided into groups Synthetic veneer, natural veneer and dyed veneer, etc. Combined veneer is also called covered veneer. The existing covered veneer is made of veneer and non-woven fabric. The composition is formed, but since most of the veneers on the market have not been sprayed with paint, they will start online after the non-woven adhesive is completed. The strips are coated with UV or PU, and the veneer fibers are easily broken. Therefore, the veneer is prone to crac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27D1/08B27M1/08C09J175/04C09J163/10C09D175/14C09D163/00C09D163/10C09D5/00

CPCB27D1/08B27M1/08C09J175/04C09D175/14C09D5/002C08L63/00C08L63/10

Inventor 洪杰施连军周勇王正伟戴仲云

Owner 小森新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com