Wellhead dismounting and mounting robot used after oil and gas well blowout out of control and ignition and using method

A technology of robots and oil and gas wells, which is applied in wellbore/well parts, earthwork drilling, measurement, etc., to achieve the effect of ensuring safety, ensuring stable operation, and long operating arms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

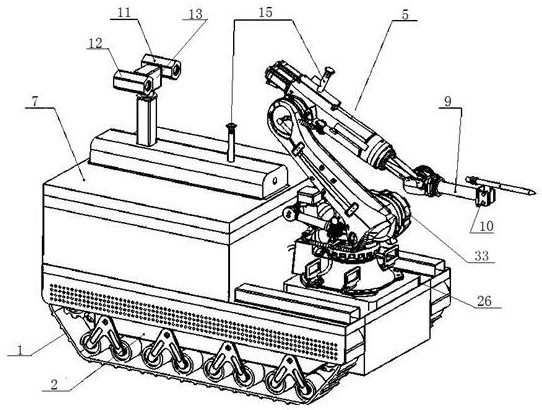

[0040] Furthermore, the walking device 1 includes two crawler belts 18, two motors 25 and two driving wheels 19, and realizes the walking and turning actions of the disassembly robot through differential drive.

[0041] Example 5

[0042] Furthermore, the load-bearing wheel 20 is made of high-strength manganese steel above 40Mn2; the driving wheel 19 and guide wheel 22 are made of ZGSiMn alloy steel, and the supporting sprocket is made of high-strength manganese steel above 50Mn , The shaft parts are made of 45# steel or 40Cr alloy steel or above, modulated and blackened.

[0043] Example 6

[0044] Example 7

Embodiment 2

[0046] Wherein, the mechanical arm assembly 5 is installed on the front end of the crawler chassis 2 to facilitate the forward detection operation of the mechanical arm, and the mechanical arm can be folded and stowed for easy transportation.

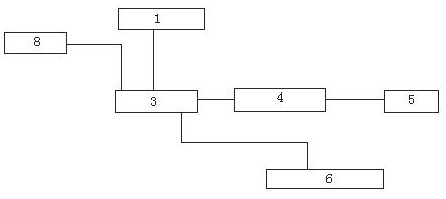

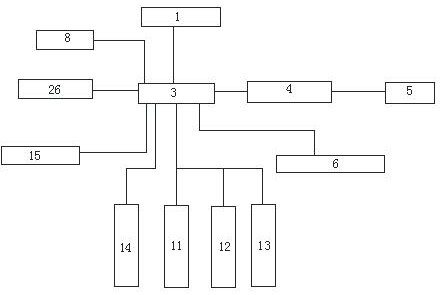

[0047] Further, the main control box 3 is connected with the walking device 1, the manipulator control box 4, the remote control terminal 6, the inverter 16, the infrared pan-tilt camera 11, the visible light camera 12, the gas detector 13, and the temperature sensor 14 respectively. It is controlled and connected with the storage battery 8, and the storage battery 8 supplies power to all electrical appliances through the main control box 3. In addition, the inverter 16 converts the direct current into the alternating current required by the manipulator assembly 5. In this embodiment, the peak power of the manipulator assembly 5 is 13.5KVA when it is fully loaded, the input voltage is 380V, and the power of the drive motor 25 is 6kW. Sin...

Embodiment 3

[0049] Further, the distal end of the mechanical arm assembly 5 is connected to a clamping device 9, and the other end of the clamping device 9 is connected to a tool head 10, and the tool head 10 is a C-shaped fastening mechanism 17, a breaking hammer, a hydraulic saw, a clamp One of them, the C-shaped fastening mechanism 17 is preferably a C-shaped mechanical locking structure, refer to Figure 5 , there is no need to increase the electric control or air control mechanism, because the failure rate of the air control or electric control device in the high temperature and water flow environment is high in the blowout out of control fire environment, which is easy to affect the normal operation, and the operation tools are damaged during the operation. Impact, long-term operation without mechanical locking will easily lead to changes in the position of the working tools, which will affect the precision control of remote control operations.

[0050] The clamping device 9 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com