Quick-setting stemming material for filling blasting hole

A technology of rapid setting and gun mud, which is applied in blasting and other directions, which can solve the problems that mechanized operations cannot be realized, and achieve the effect of improving blasting effect, good continuity, and good fluidity of single slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The quick-setting mud material provided by the embodiment of the present invention is composed of two kinds of composite materials, A and B, and is suitable for making quick-setting mud.

[0031] The materials A and B are solid materials, which can be prepared by adding water and mixing to form solid quick-setting mud.

[0032] The quick-setting clay composite material A comprises: sulfoaluminate cement clinker, bentonite, retarder and dispersant.

[0033] Specifically, by mass percentage, the sulfoaluminate cement clinker is 80.5-94.1%, the bentonite is 4.7-14.9%, the retarder is 0.27-3%, and the dispersant is 0.09-2.1%.

[0034] In some embodiments of the present invention, the A material further comprises: a suspending agent. The mass percentage of the suspending agent is 0.18% to 2.1%.

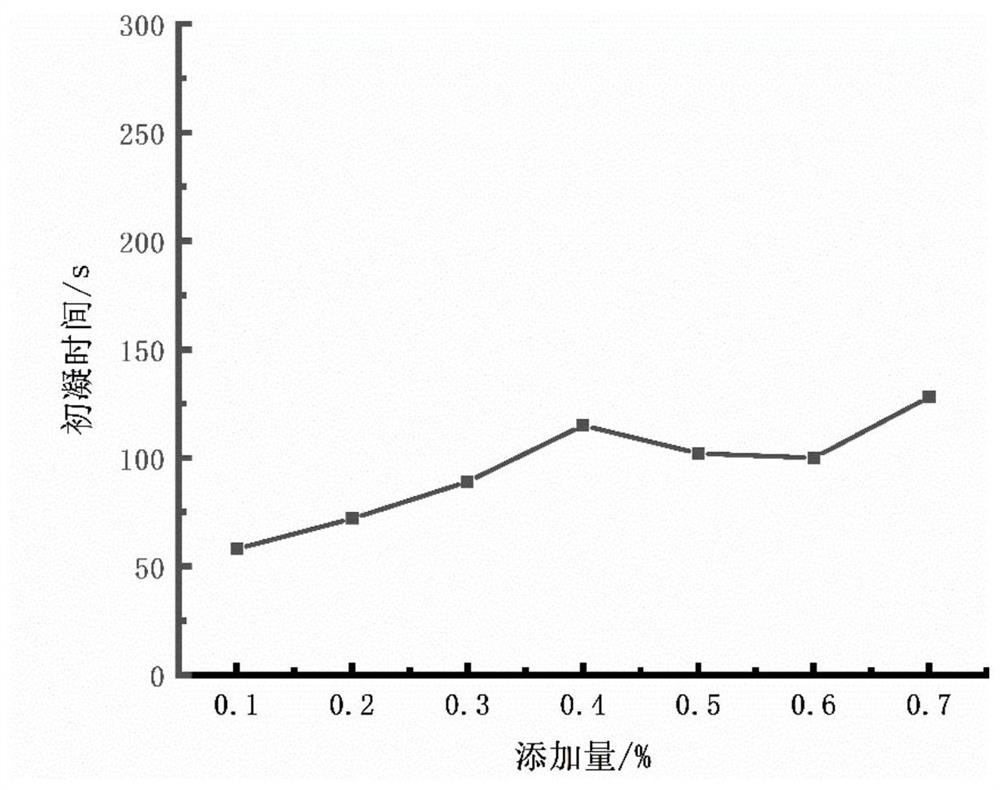

[0035] Further, the retarder is one or a combination of two or more of citric acid, glucose and sorbitol.

[0036] The dispersant is one or a combination of calcium lignosulfonat...

preparation example 1

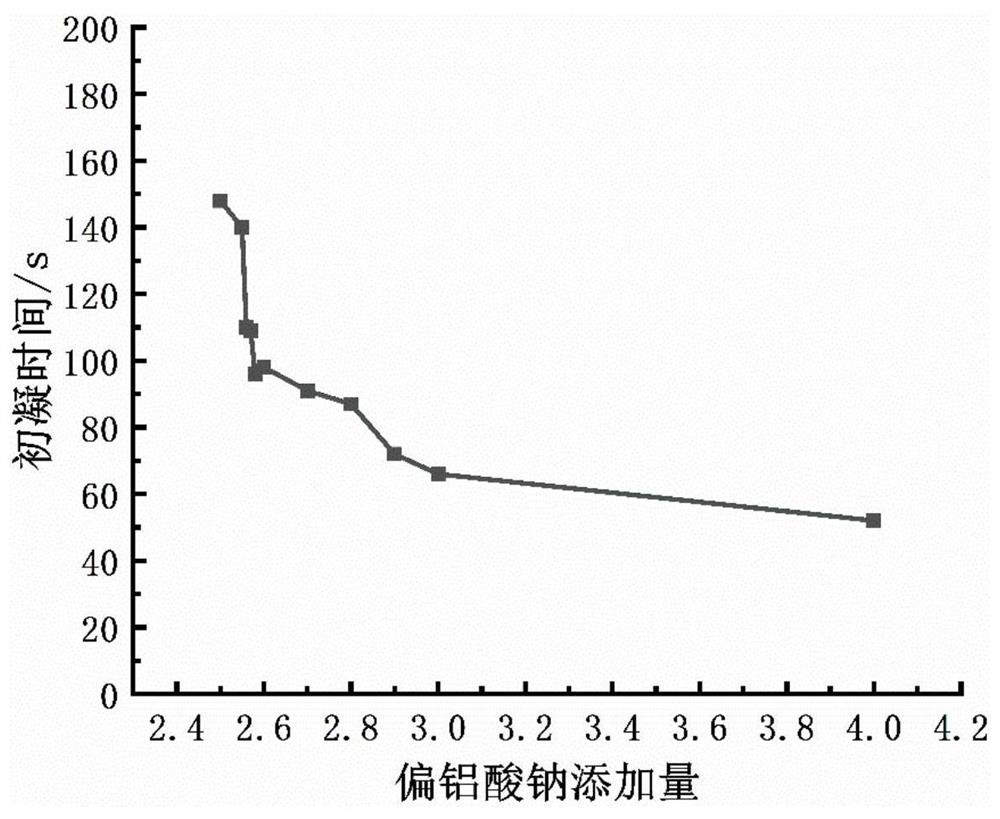

[0063] Get the A material and B material of following mass percentage, A material comprises: 36kg sulfoaluminate cement, 4kg bentonite, 0.36kg glucose, 0.16kg calcium lignosulfonate; Quick lime 5.2kg, calcium carbonate 10kg, sodium metaaluminate 1.2kg, lithium carbonate 0.12kg.

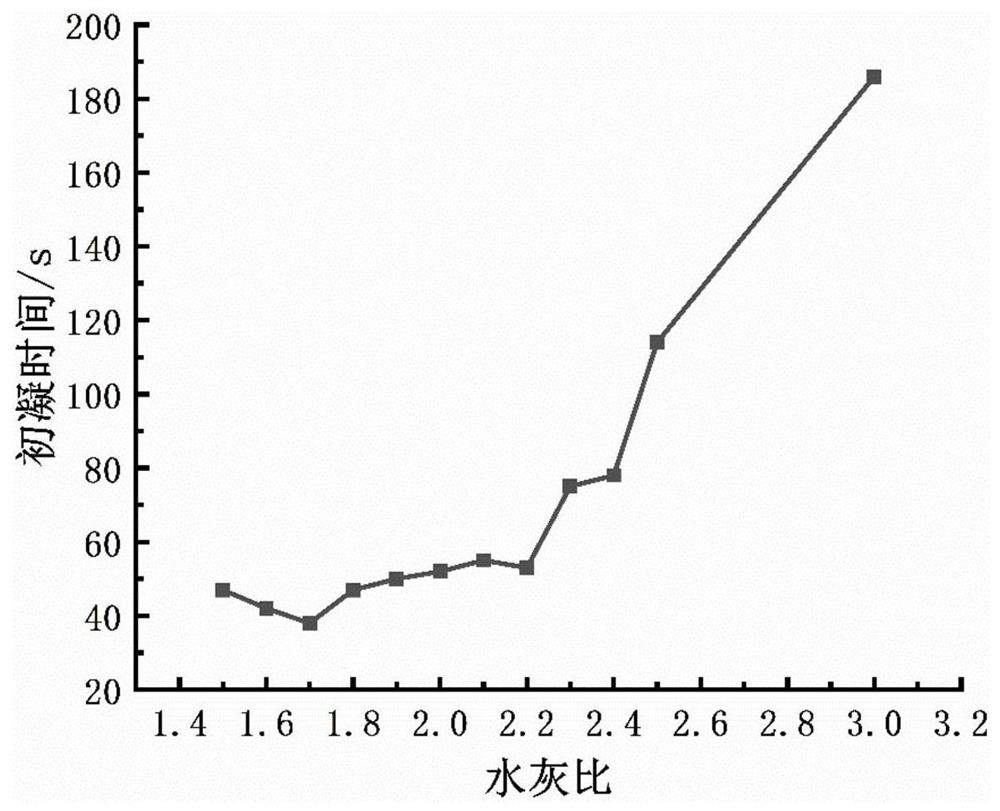

[0064] Add water to material A and stir, and the mass ratio of material A and water is 1:2; add water to material B, and stir, and the mass ratio of material B and water is 1:2; the A slurry and B slurry formed after adding water and stirring are in volume ratio. 1:1 mixed uniformly to obtain quick-setting gun mud slurry. The initial setting time of the quick-setting mud slurry is 1min30s, the final setting time is 30min, and the final setting strength is not less than 0.2MPa. Among them, the aforementioned equipment can be used for stirring and mixing.

preparation example 2

[0066] The components of quick-setting clay are prepared according to the following mass percentages of raw materials:

[0067] Material A is composed of the following raw materials by mass percentage: 36kg sulfoaluminate cement, 2kg bentonite, 0.4kg glucose, 0.24kg citric acid, 0.48kg sodium tripolyphosphate, 0.12kg xanthan gum; Material B is composed of the following raw materials by mass percentage Composition: 22kg of quicklime gypsum, 6kg of quicklime, 9.6kg of calcium carbonate, 1.4kg of sodium metaaluminate, and 0.24kg of lithium chloride.

[0068] Add water to material A and stir, and the mass ratio of material A to water is 1:1.5; add water to material B, and stir, and the mass ratio of material B to water is 1:2; the A slurry and B slurry after adding water and stirring are in a volume ratio of 1 : 1 Mix evenly to obtain quick-setting gun mud slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com