Telescopic nozzle capable of spraying stable airflow for gas shielded welding and using method of telescopic nozzle

A technology of gas shielded welding and stable gas flow, which is applied to devices, welding equipment, welding accessories, etc. for supplying/exhausting shielding gas. Gas protection effect, improve arc stability, eliminate meshing gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

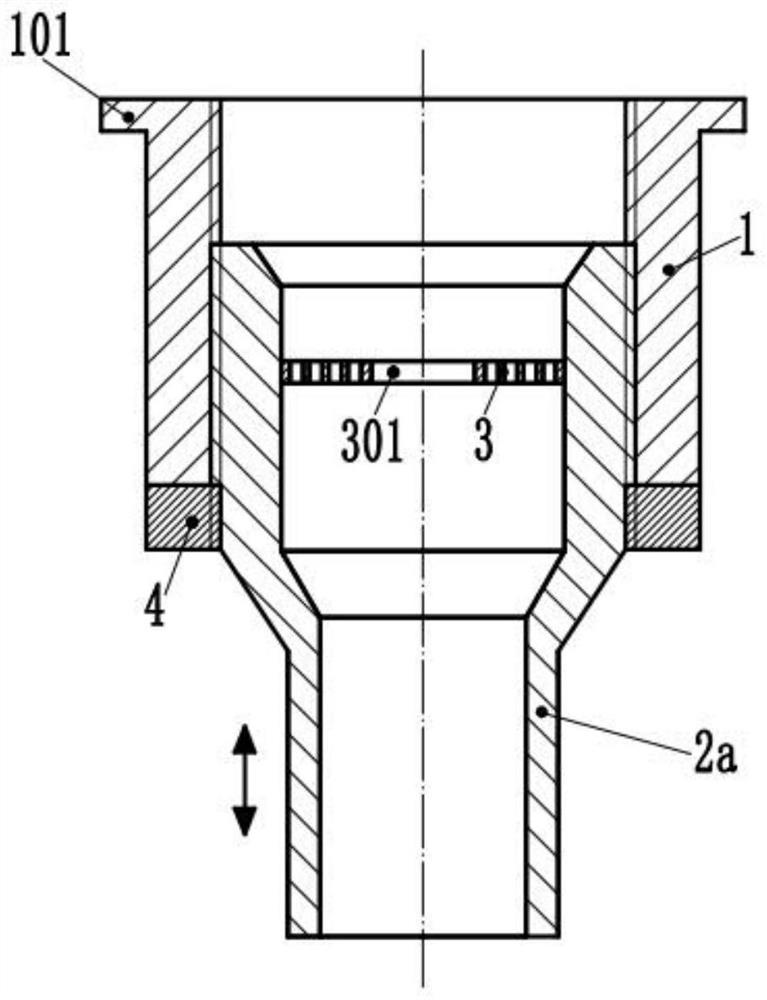

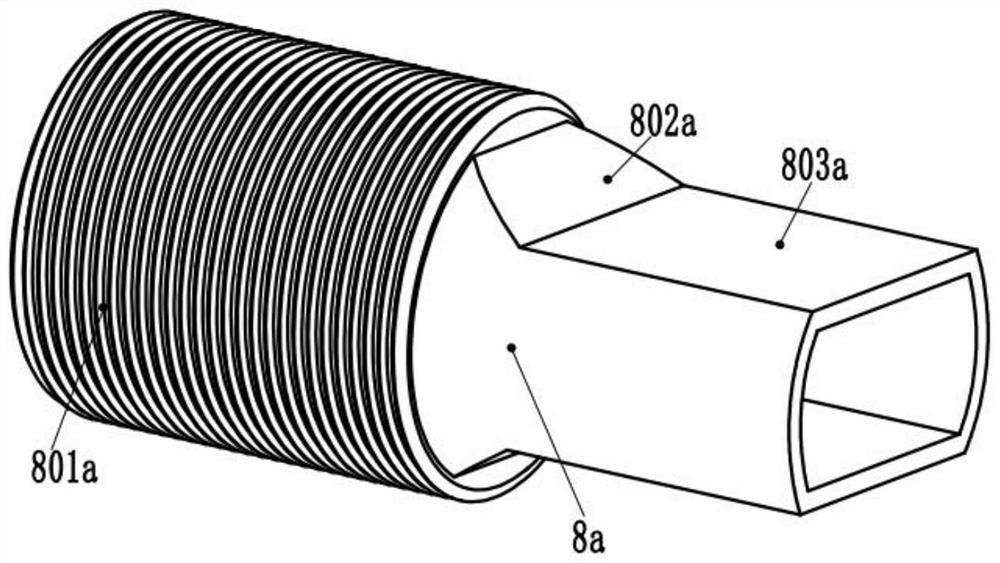

[0046] like figure 1 As shown, a retractable nozzle for gas shielded welding capable of ejecting stable airflow includes a nozzle seat 1 , a first retractable sleeve 2 a , a gas screen 3 , and a locking nut 4 . Among them, the nozzle seat 1 is a hollow tubular body with internal threads, and its top is provided with a flanging flange 101; the first telescopic sleeve 2a is a circular funnel-shaped hollow tubular body, the upper part is provided with external threads, and its inner cavity is In the shape of a round funnel, the upper part of the inner cavity can be provided with a figure 1 As shown in the chamfer, the upper part of the inner cavity (which can go up to the top) is provided with a gas screen 3, and the center of the gas screen 3 is provided with a through hole 301 for a welding torch conducting rod or a welding torch electrode; the gas screen 3 is preferably fitted with an interference fit. It is fixedly connected with the upper part of the inner cavity of the fir...

Embodiment 2

[0051] On the basis of Embodiment 1, a locking protective sleeve 5 is used to replace the locking nut 4, and the rest of the structure of the nozzle is the same as that of Embodiment 1. An example of the connection relationship between the locking protective sleeve 5 and the first telescopic sleeve 2a, such as Figure 4 shown. The locking protective sleeve 5 is a hollow sleeve body, the upper part (head) of which is provided with an inner thread that cooperates with the outer thread of the upper part of the first telescopic sleeve 2a, and the lower part is provided with a center for movably wearing the first telescopic sleeve 2a Through hole, the central through hole is cylindrical (not shown) or cylindrical with large upper and lower steps (see Figure 4 ) of the light hole; the locking protective sleeve 5 is screwed up on the lower section of the upper outer thread of the first telescopic sleeve 2a through the inner thread on the first inner flange 501 and the head thereof,...

Embodiment 3

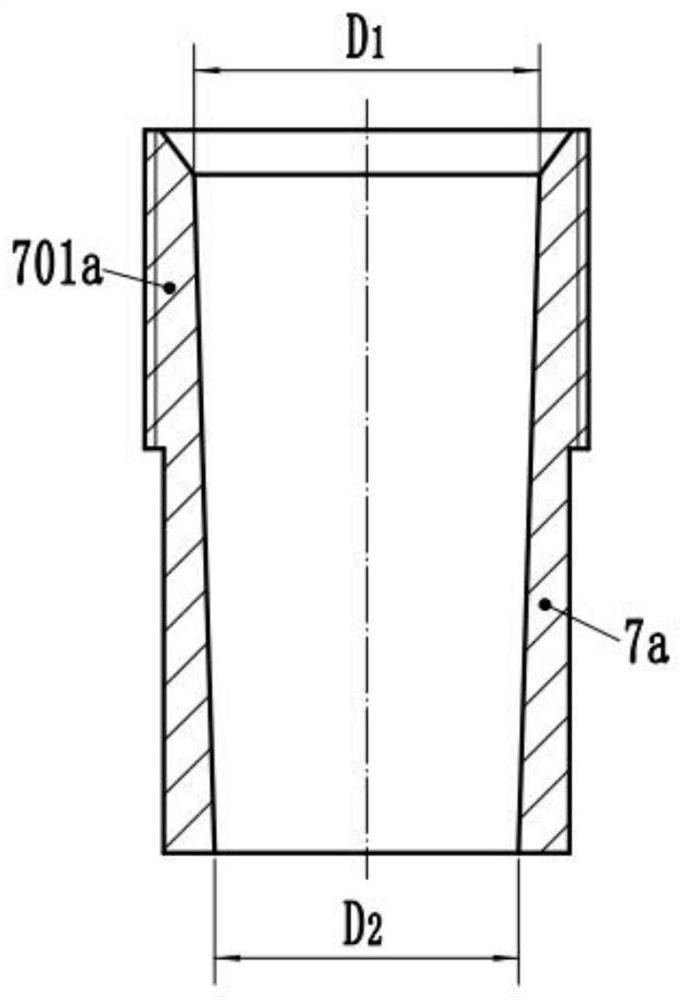

[0055] On the basis of Embodiment 1, the fourth telescopic sleeve 2b is used to replace the first telescopic sleeve 2a, and the dust sleeve 9 is used to replace the locking nut 4. The rest of the structure of the nozzle is the same as that of Embodiment 1. The nozzle includes a nozzle seat 1 , a fourth telescopic sleeve 2 b , a gas screen 3 , and a dust jacket 9 . like Figure 5 As shown, the fourth telescopic sleeve 2b is a circular funnel-shaped hollow tubular body, the upper part of the upper part is provided with a fully threaded external thread, the lower part is a smooth outer surface, and the upper part of the inner cavity (can go up to the top) is provided with a gas screen 3 The diameter of the root circle of the outer thread of the upper section of the fourth telescopic sleeve 2b is greater than the diameter of the smooth outer surface of the lower section, and the length of the outer thread of the upper section is preferably the shortest meshing full thread section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com