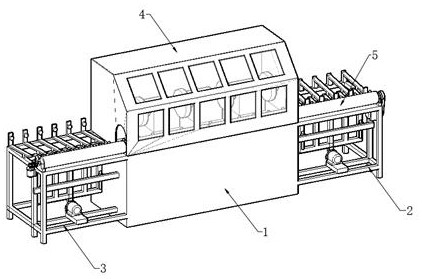

Automatic feeding, discharging and polishing device for piston rod pieces

An automatic loading and unloading and polishing device technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding workpiece supports, etc., can solve the problems of low processing efficiency, time-consuming and laborious, etc., to improve processing quality and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

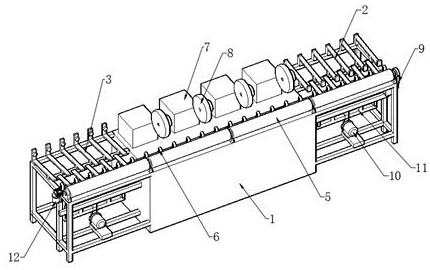

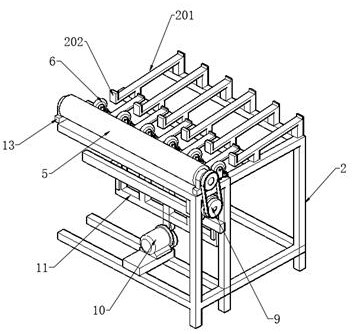

[0036] When in use, the piston rod is automatically loaded and unloaded and polished. The piston rod to be processed is placed on the bracket one 201 of the loading rack 2. Due to the tilt of the bracket one 201, the piston rod approaches the rotating roller 5 and passes through the lifting frame 11. The rise of the top plate 1101 drives a piston rod to lift, and the piston rod rolls on the inclined surface of the top plate 1101 and falls into the upper part of the roller 5 and the supporting wheel 6. Through the rotation of the rotating roller 5 and the inclination of the supporting wheel 6, it is aligned with the axis of the rotating roller 5 The center forms an included angle, so that the piston rod moves toward the direction of the polishing machine 7, and the piston rod is sequentially polished through the polishing wheel with the polishing accuracy set from coarse to fine, and the processing is in place at one time, which improves the processing quality and processing effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com