Hydraulic horizontal extrusion type impurity separation equipment for water-containing viscous sludge material

A separation equipment and extrusion technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of large land occupation and investment, high treatment cost, complex treatment process, etc. , to achieve the effects of small footprint, high work efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

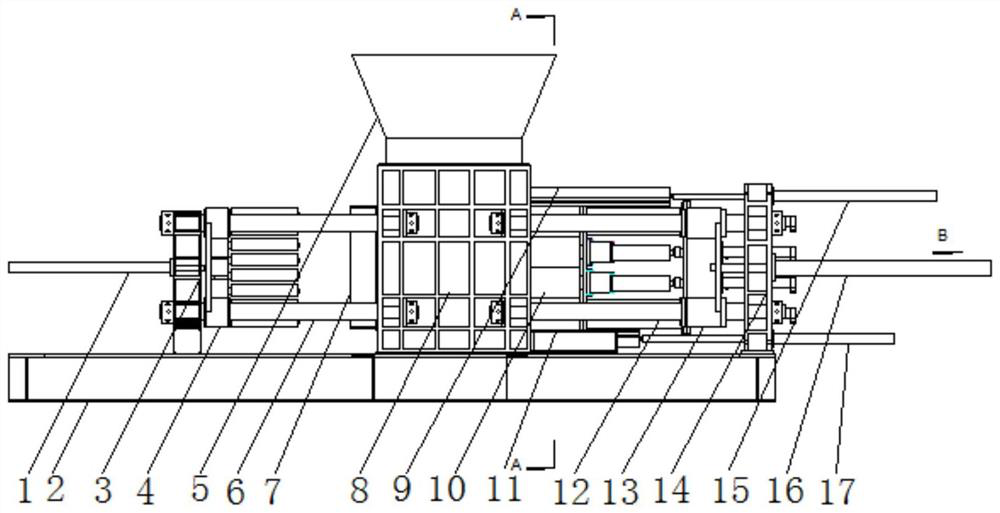

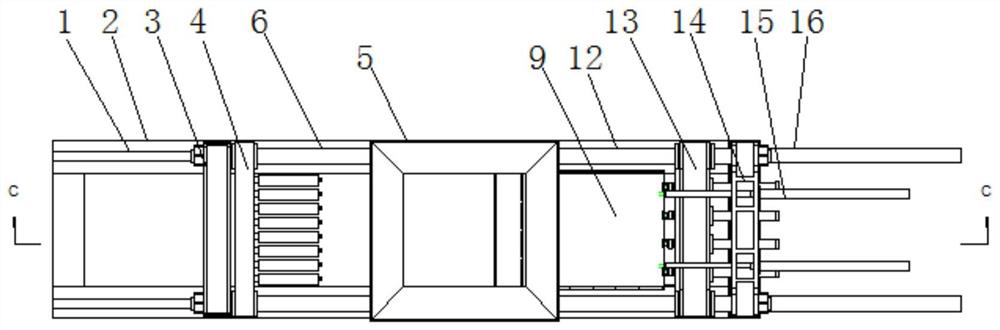

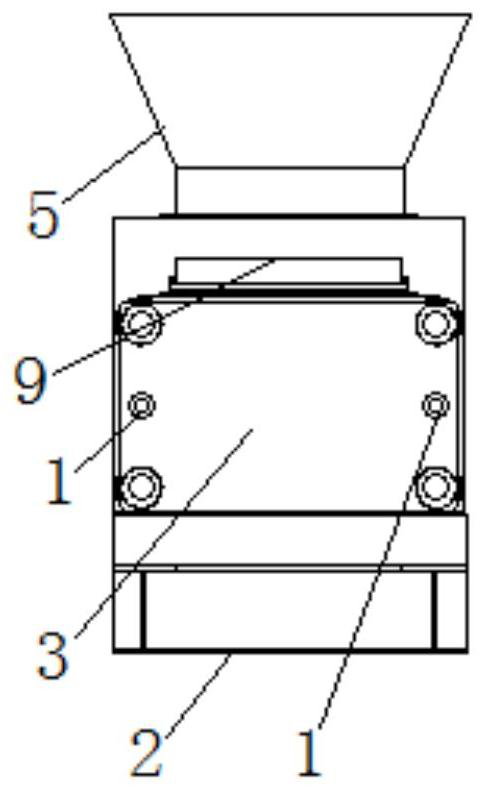

[0059] like Figure 1-18 A hydraulic horizontal extrusion impurity separation equipment for water-containing viscous sludge material, comprising a structural chassis 2, one end of the structural chassis 2 is provided with an impurity cleaning structure, and a middle position of the structural chassis 2 is provided with a feeding material For the material storage structure, the other end of the structural bottom frame 2 is provided with an extrusion structure, and the material loading and material storage structure includes a sludge tank 8 . The structural bottom frame 2 is a steel structure. Its function is to serve as the basis for the installation of all components, to carry the weight of the entire equipment, and to have certain rigidity and strength.

[0060] Described cleaning structure includes cleaning hydraulic oil cylinder 1, structure chassis 2, cleaning end fixed beam 3, cleaning movable structure 4 and cleaning end column 6, and described cleaning end fixed beam 3...

Embodiment 2

[0071] The difference from the first embodiment is that the combination Figure 17-18 As shown, the extrusion head assembly is an extrusion head assembly without a sealing structure, and each group is mainly composed of a sub-cylinder 10.1, a square extrusion head 10.6 and a hinged joint 10.7, wherein each square extrusion head 10.6 is mainly composed of It is composed of a conical section 10.6.1, a diamond section 10.6.2 and a square section 10.6.3; in the same group of extrusion head assemblies 10, the cylinder part of the sub-cylinder 10.1 is fixed in a corresponding one of the extrusion movable beams 13 At the installation hole 13.2 of the oil sub-cylinder, the piston rod is connected with a hinged joint 10.7, and the other end of the hinged joint 10.7 is connected with the conical section 10.6.1 of the square extrusion head 10.6. One end is fixed on one side plane of the extruding movable beam 13, and the conical section 10.6.1 of each group of square extruding heads 10.6...

Embodiment 3

[0074] The difference from the first embodiment is that the combination Figure 19-23 As shown, the extrusion head assembly is an extrusion head assembly without a sealing structure. A second square extrusion head 10.91 consists of a second square pressure head body 10.9.11 and a second hinged joint 10.71 fixedly connected with it. Multiple groups of extrusion head assemblies without a sealing structure are stacked together, Together with the extrusion head mounting seat 10.31, the square extrusion head guide 10.81, and the elastic scraper assembly 10.10, a complete extrusion head assembly is formed.

[0075] Its working principle is:

[0076] The initial state is as follows: the upper sealing door 9 moves forward to the frontmost position, and separates the sludge temporary storage bin 5 from the sludge hopper 8 cavity. The lower sealing door 11 moves forward to the foremost position to cut off the cavity of the sludge bin 8 from the outside. The complete extrusion head as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com