Method for producing marine fuel oil by hydrogenation

A technology for generating oil and fuel oil by hydrogenation, which is applied in the direction of hydrotreating process, processing hydrocarbon oil, petroleum industry, etc., can solve the problems of increasing difficulty in product blending, increasing production cost, increasing conversion rate, etc., and improving the metal-holding capacity. , enhance the adaptability, prevent the effect of excessive hydroconversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

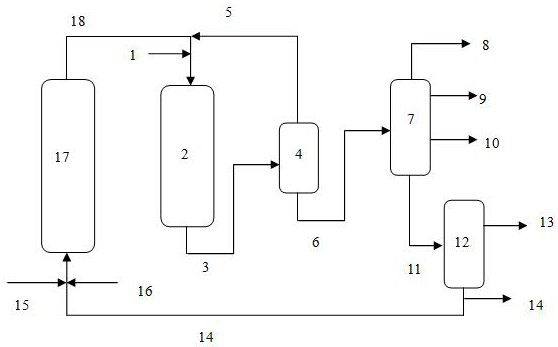

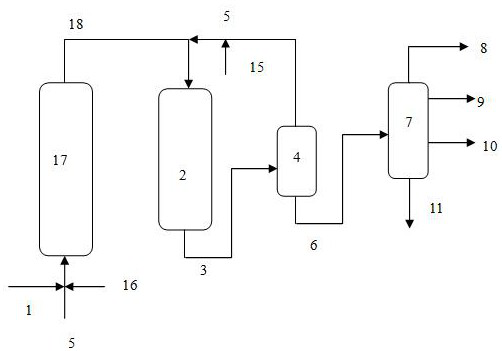

This example uses the production method of fuel oil for low -sulfur ships provided by the present invention (see figure 1 ), Use relatively good slag oil raw materials A and relatively poor slag oil raw material B, see Table 1 in nature.The relatively good properties of the residue oil raw material A and the relatively poor properties of the residue oil raw material B with a relatively good properties are 7: 3.

[0044] The device fixed bed reactor adopts three series in series, one of which is filled with two kinds of residue oil hydrogenation protective agents, and the filling volume is FZC-12B catalyst 60ml, FZC-103E catalyst 90ml; the second reflection fills the two kinds of residue oil dehydrated metal metalThe catalyst, the filling volume of the FZC-28A catalyst is 70ml, the FZC-204 catalyst is 170ml; the three-counter-filling oil hydrogen desulfurization catalyst FZC-34A, the filling volume is 240ml.See Table 2 in nature.

[0045] The upper-end reactor of the device uses one...

Embodiment 2

It can be seen from Table 9 and 10. Examples 1-3 can be seen that the hydrogenation wax oil of different ratios can achieve the requirements of different viscosity, and at the same time meet the sulfur content of less than 0.5%, and other indicators can meet the quality of fuel oil.Hydrogenation wax oil is good. On the one hand, it can be used as a high value -added product for hydrogenation cracking and catalytic catalytic raw materials. On the other hand, hyluding constant residue can add different proportion of hydrogen wax oil to produce different viscosity ships with different viscosity.product.The method of the present invention flexibly produces fuel products for low -sulfur ships, and at the same time, it can well meet companies that want to increase the yield of light oil.

[0050] In addition, it can be seen that the upper -line hydrogen reactor is used to treat hydrogenation and decompressive residue oil to make it deeply desulfurize, while the saturated score in the pro...

Embodiment 3

[0055] In addition, among the hydrogenation products obtained by proportional 1, the revenue of aromatic hydrocarbons was 22.87%, the glue content was 9.10%, and the total of the two reached 35%.It can be seen that in order to realize the high hydrogenation depth of impurities and viscosity, the content of saturated hydrocarbons has reached 66.38%.However, excessive saturated hydrocarbon content and lower glue and aromatic hydrocarbons content affects the stability of the system of oil, which is not conducive to the storage and transportation of ship fuel oil, and then affects its performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com