Catalytic cracking unit

A catalytic cracking unit, a technology for regenerating catalysts, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of deteriorating product distribution, long oil and gas reaction time, long reaction time, etc., to improve coke strength and coke efficiency, The effect of shortened residence time and easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1, comparative example

[0088] Experiments were carried out on a conventional double-riser catalytic cracking pilot plant. The heavy oil riser reactor processes straight-run wax oil transported by Luning Pipeline, and the light hydrocarbon riser reactor processes catalytic gasoline produced by the heavy oil riser reactor. The catalyst adopts commercially available CC-20D catalytic cracking industrial equilibrium catalyst.

[0089] The design capacity of the heavy oil riser reactor is 60kg / d, simulating the full back refining operation, the heavy oil raw material is mixed with the recycle oil and enters the heavy oil riser reactor through the feed nozzle; the design capacity of the light hydrocarbon riser reactor is 24kg / d . The carbon content of the regenerated catalyst is 0.03w%, and the microreaction activity is 62. The stripping medium in the stripping section is steam, and the stripping temperature is 500°C.

[0090] The properties of the catalytic cr...

Embodiment 2

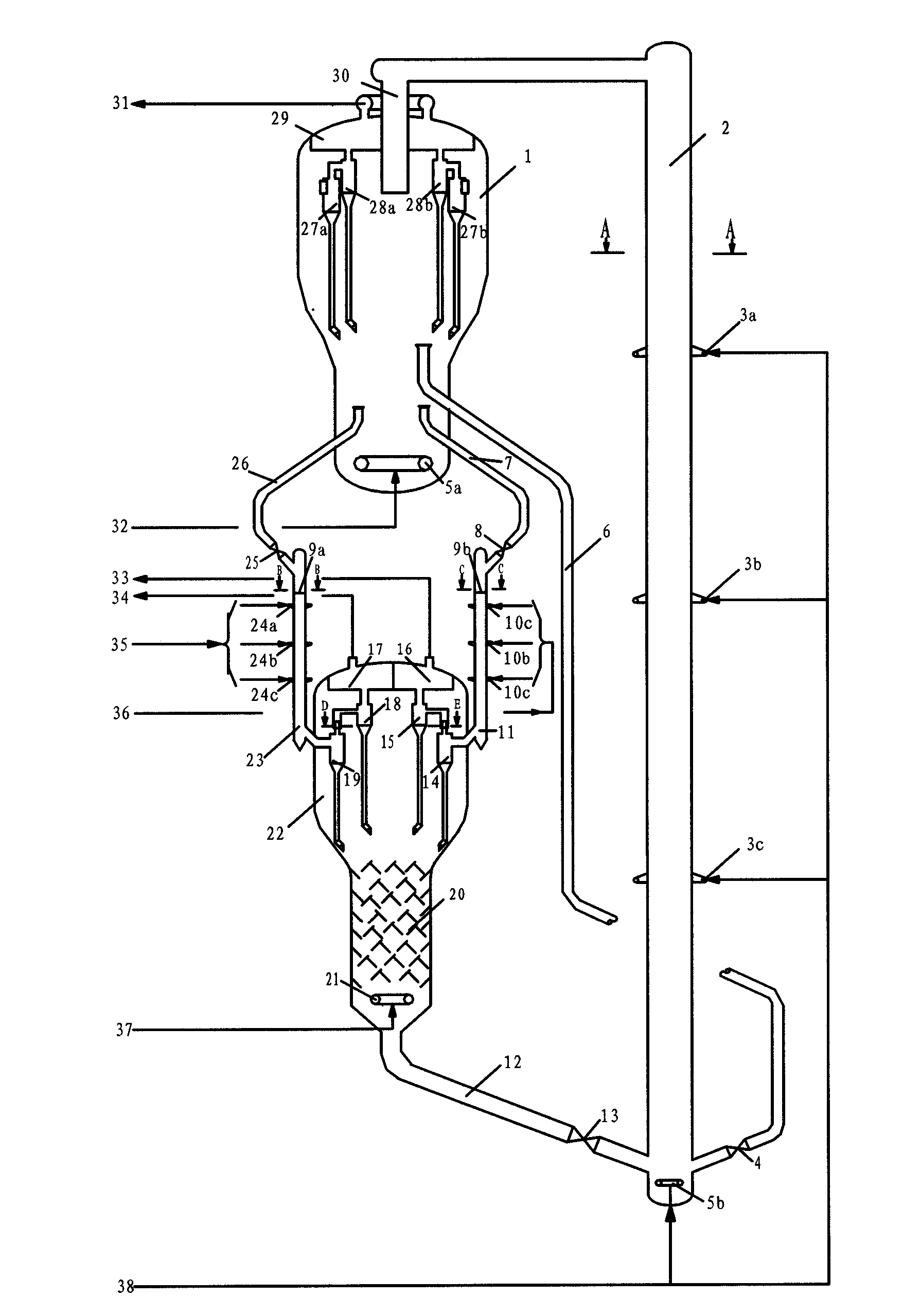

[0092] Test on the novel fluid catalytic cracking pilot plant that is similar to the device shown in Figure 1. Both the heavy oil downcomer reactor and the light hydrocarbon downcomer reactor of the new fluid catalytic cracking pilot plant can be flexibly replaced according to process requirements. The heavy oil down-pipe reactor processes straight-run wax oil from the Luning pipeline that is the same as the comparative example, and the light hydrocarbon down-pipe reactor processes the catalytic gasoline produced by the heavy oil down-pipe reactor. The catalyst is commercially available CC-20D that is the same as the comparative example Cracking industry equilibrium catalyst.

[0093] The design capacity of the heavy oil down tube reactor is 60kg / d, simulating the full back refining operation, the heavy oil raw material is mixed with the recycle oil and enters the heavy oil down tube reactor through the feed nozzle; the designed capacity of the light hydrocarbon down tube reac...

Embodiment 3

[0096] According to Example 2, the main difference lies in the scorch intensity and scorch time of the turbulent bed regenerator and the riser regenerator, the average gas linear velocity of the riser regenerator, and the reaction time and recycling ratio of the heavy oil downcomer reactor. See Table 6 for the main operating conditions and product distribution of the new FCC unit implemented in this implementation. The main properties of the liquid products of the new fluid catalytic cracking unit are shown in Table 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com