Torsion shaft manufacturing process

A manufacturing process and torsion shaft technology, applied in the field of torsion shaft manufacturing technology, can solve the problems of waste of materials, laborious manufacturing process, cumbersome procedures, etc., and achieve the effect of saving materials, saving processing procedures, and improving material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

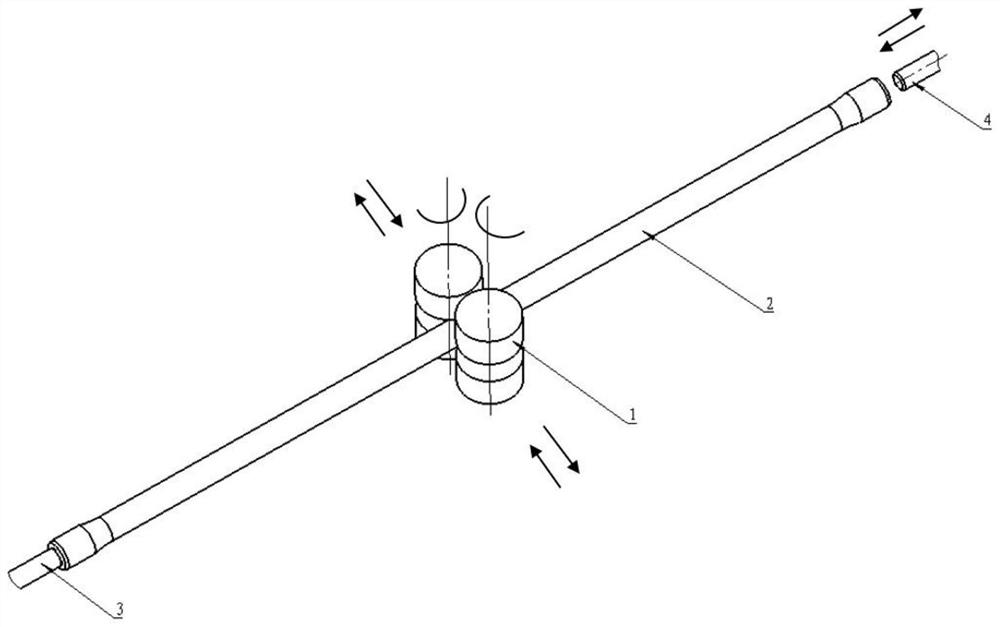

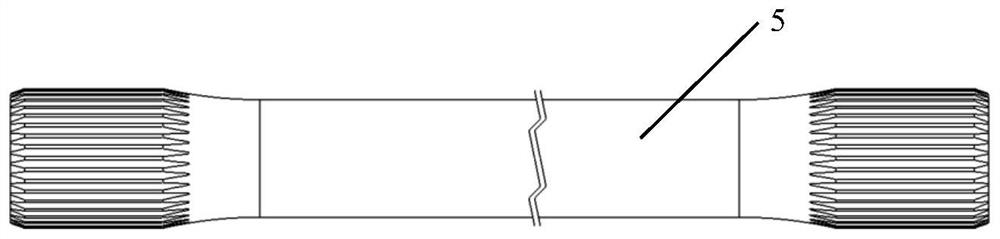

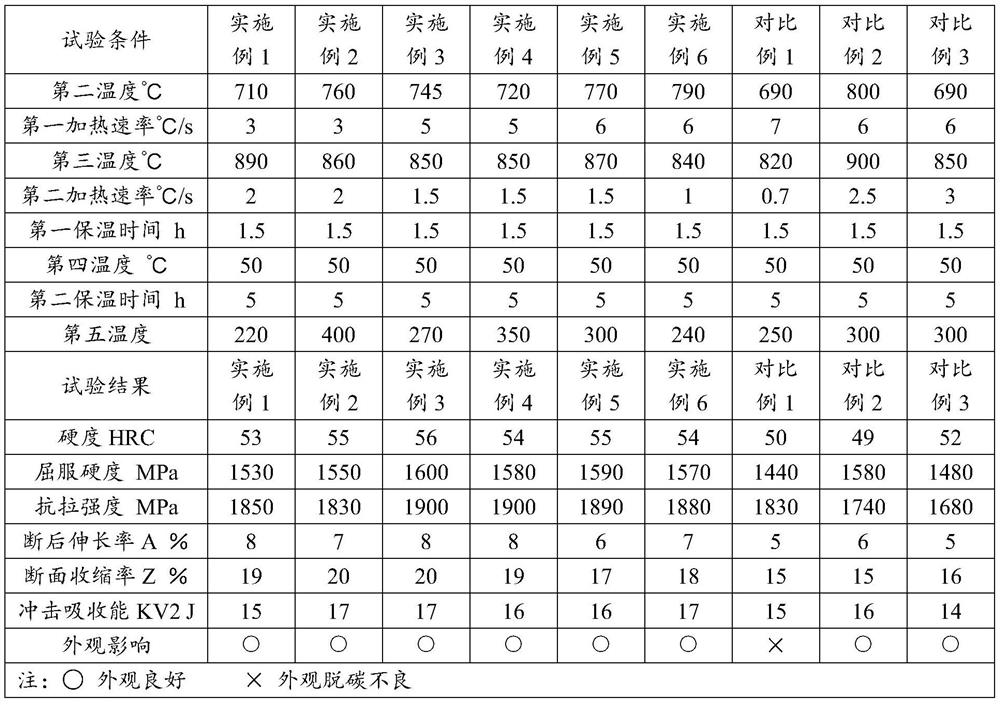

[0028] Refer below figure 1 A method for manufacturing a torsion shaft provided in this preferred embodiment is described, including: material preparation: selecting a rough rod material of 45CrNiMoVA alloy steel, and sawing the rough rod according to the length of the torsion shaft to obtain a pretreated rough rod; Cold rolling preparation: put the pretreated rough bar into the cold rolling equipment: place the rough bar in the middle of two symmetrically arranged rollers, the two rolls are close to clamp the rough bar, and the two ends of the rough bar are respectively connected to the driven clamping shaft and drive shaft; cold rolling forming: the drive shaft moves back and forth along the axis, the blank rod moves back and forth with the drive shaft in the state of clamping the roll, the blank rod is deformed and elongated to the required final length, and the roll is loosened to obtain a prototype Torsion shaft; the length of the driven clamping shaft shortens with the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com