Treatment method and treatment device for zero discharge and reuse of coking wastewater

A technology of coking wastewater and treatment methods, which is applied in the direction of oxidation water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., and can solve the problems of long-term stable operation of the process system, inorganic salt scaling, process connection design or operation. Unreasonable and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

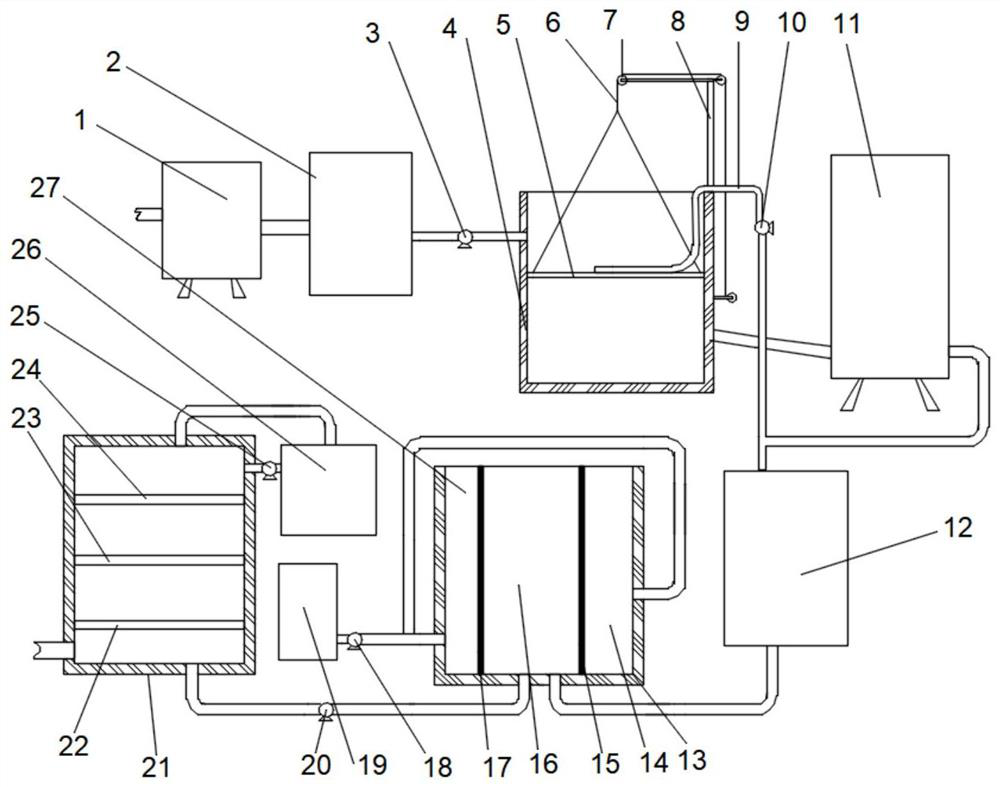

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art fall within the protection scope of the present invention.

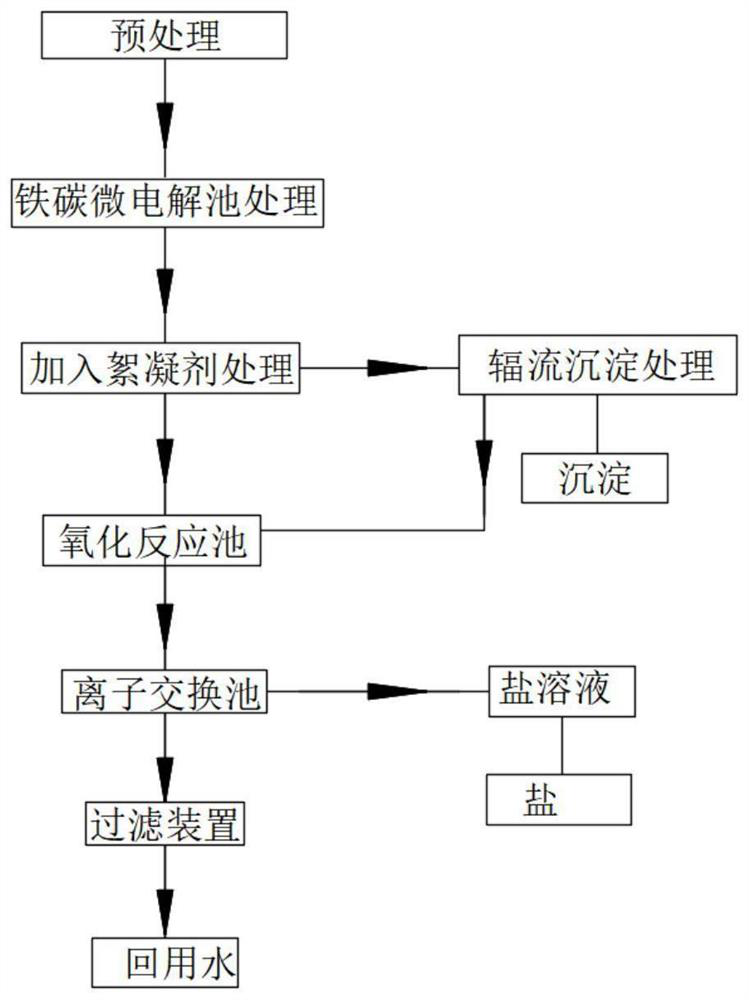

[0038] like figure 1 As shown in the figure, a treatment method for zero discharge and reuse of coking wastewater includes the following steps:

[0039] Pass the coking wastewater into the micro-nano air flotation degreasing equipment for pretreatment. The micro-nano air flotation degreasing equipment accelerates the gas-liquid mixed liquid through a high-speed vortex. Bubbles with diameters between 30 microns and 0.5 nanometers are formed by compressing the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com