Composite gypsum retarder and preparation method thereof

A gypsum retarder and composite technology, applied in the field of gypsum building materials, can solve the problems of large dosage, difficult control of retarding time, unsatisfactory strength loss, etc., and achieve small strength loss and long retarding time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

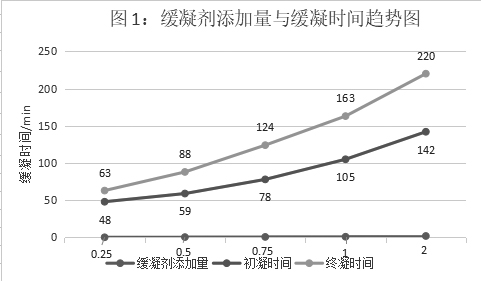

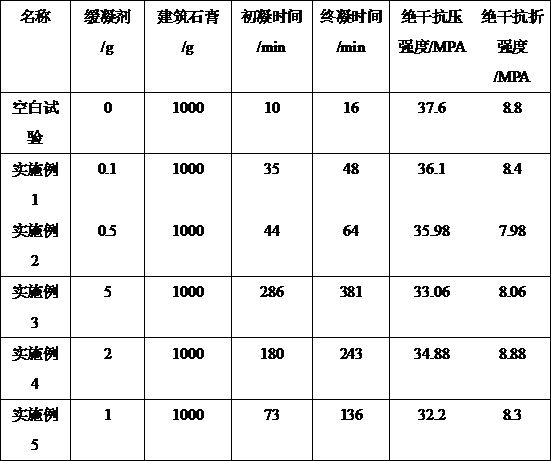

Examples

Embodiment 1

[0034] This embodiment discloses a composite gypsum retarder, which is prepared according to mass percentage from the following components: 28 parts of itaconic acid-p-aminostyrene phosphoric acid copolymer, 15 parts of magnesium nitrate, hydroxyethylidene diphosphine 15 parts of disodium acid, 20 parts of sodium sulfamate.

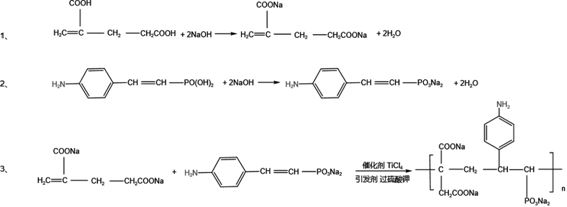

[0035] In this embodiment, the preparation method of above-mentioned itaconic acid-p-aminostyrene phosphoric acid copolymer, comprises the following steps:

[0036] 1) Add itaconic acid, p-aminostyrene phosphoric acid, deionized water and catalyst to the reactor in turn, heat in a constant temperature water bath, stir to dissolve itaconic acid and p-aminostyrene phosphoric acid, add sodium hydroxide The pH value of the solution was kept at 8.5 to obtain a reaction solution;

[0037] 2) Under a nitrogen atmosphere, maintain the temperature at 75°C, add the initiator dropwise to the reaction solution at a constant speed, heat to reflux and mechanically sti...

Embodiment 2

[0047] This embodiment discloses a composite gypsum retarder, which is prepared according to the mass percentage from the following components: 50 parts of itaconic acid-p-aminostyrene phosphoric acid copolymer, 15 parts of magnesium ammonium phosphate, hydroxyethylidene 13 parts of tetrasodium diphosphonate and 25 parts of sodium m-sulfanilate.

[0048] In this embodiment, the preparation method of above-mentioned itaconic acid-p-aminostyrene phosphoric acid copolymer, comprises the following steps:

[0049] 1) Add itaconic acid, p-aminostyrene phosphoric acid, deionized water and catalyst to the reactor in turn, heat in a constant temperature water bath, stir to dissolve itaconic acid and p-aminostyrene phosphoric acid, add sodium hydroxide The pH value of the solution was kept at 8.5 to obtain a reaction solution;

[0050] 2) Under a nitrogen atmosphere, maintain the temperature at 75°C, add the initiator dropwise to the reaction solution at a constant speed, heat to reflu...

Embodiment 3

[0060] This embodiment discloses a composite type fluoride removing agent, which is prepared from the following components according to the mass percentage: 30 parts of itaconic acid-p-aminostyrene phosphoric acid copolymer, 25 parts of magnesium tartrate, 2-phosphonic acid butane -20 parts of tetrasodium 1,2,4-tricarboxylate and 5 parts of potassium sulfamate.

[0061] In this embodiment, the preparation method of above-mentioned itaconic acid-p-aminostyrene phosphoric acid copolymer, comprises the following steps:

[0062] 1) Add itaconic acid, p-aminostyrene phosphoric acid, deionized water and catalyst to the reactor in turn, heat in a constant temperature water bath, stir to dissolve itaconic acid and p-aminostyrene phosphoric acid, add sodium hydroxide The pH value of the solution was kept at 8.5 to obtain a reaction solution;

[0063] 2) Under a nitrogen atmosphere, maintain the temperature at 75°C, add the initiator dropwise to the reaction solution at a constant spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com