Method for producing humic acid based on natural biomass

A humic acid and biomass technology, applied in the field of agricultural solid waste recycling, can solve the problems of unstable product and conversion rate, low conversion rate of natural biomass, low yield of humic acid, etc., to improve product characteristics and increase raw material Utilization rate, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of biomass-based humic acid, comprising the steps:

[0040] Pyrolysis of S1 biomass

[0041] Wash and dry the rice straw, cut it into pieces to a length of less than 0.1 cm, take a certain amount of it and place it in an atmosphere furnace, and under nitrogen protection, raise the temperature to 200 °C at a rate of 5 °C / min and maintain it for 1 h to obtain rice straw. bio-charcoal;

[0042] S2 hydrothermal base catalysis

[0043] Take 1 g of the biochar obtained in S1, add it to a hydrothermal reaction kettle, add 2 g of sodium hydroxide and 50 ml of deionized water to the reaction kettle, heat it with water at 200 ° C for 12 h, and filter out the residue after cooling to obtain a humic acid liquid;

[0044] S3 liquid to adjust acid, collect solid

[0045] Take 5 ml of the humic acid liquid prepared in S2, dropwise add 1M hydrochloric acid until pH is less than 2, centrifuge, and pour off the supernatant to obtain solid humic acid.

Embodiment 2

[0047] A preparation method of biomass-based humic acid, comprising the steps:

[0048] Pyrolysis of S1 biomass

[0049] Wash and dry the rice straw, cut it into pieces to a length of less than 0.1 cm, take a certain amount and place it in an atmosphere furnace. Under nitrogen protection, the temperature is raised to 250 °C at a rate of 5 °C / min and maintained for 1 h to obtain rice straw. bio-charcoal;

[0050] S2 hydrothermal base catalysis

[0051] Take 1 g of the biochar obtained in S1, add it to a hydrothermal reaction kettle, add 2 g of sodium hydroxide and 50 ml of deionized water to the reaction kettle, heat it with water at 200 ° C for 12 h, and filter out the residue after cooling to obtain a humic acid liquid;

[0052] S3 liquid to adjust acid, collect solid

[0053] Take 5 ml of the humic acid liquid prepared in S2, dropwise add 1M hydrochloric acid until pH is less than 2, centrifuge, and pour off the supernatant to obtain solid humic acid.

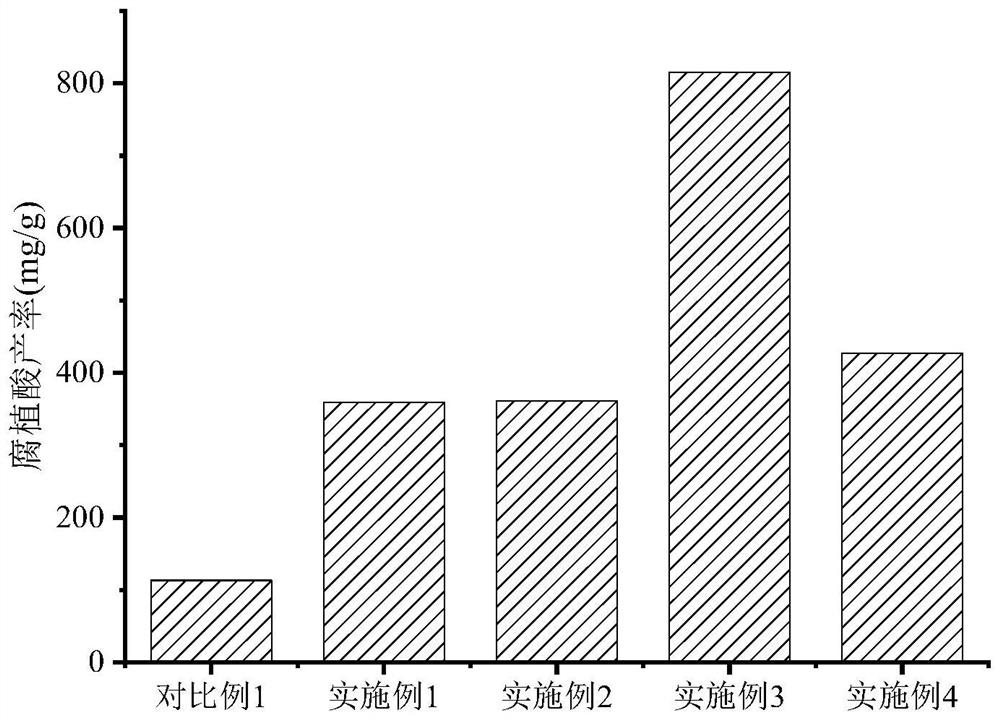

Embodiment 3

[0055] A preparation method of biomass-based humic acid, comprising the steps:

[0056] Pyrolysis of S1 biomass

[0057] Wash and dry the rice straw, cut it into pieces to a length of less than 0.1 cm, take a certain amount and place it in an atmosphere furnace, and under nitrogen protection, raise the temperature to 300 °C at a rate of 5 °C / min and maintain for 1 h to obtain rice straw. bio-charcoal;

[0058] S2 hydrothermal base catalysis

[0059] 1 g of biochar at different temperatures prepared by S1 was added to a hydrothermal reaction kettle, 2 g of sodium hydroxide and 50 ml of deionized water were added to the reaction kettle, hydrothermally heated at 200 ° C for 12 h, and the residue was filtered off after cooling to obtain humic acid liquid ;

[0060] S3 liquid to adjust acid, collect solid

[0061] Take 5 ml of the humic acid liquid prepared in S2, dropwise add 1M hydrochloric acid until pH is less than 2, centrifuge, and pour off the supernatant to obtain solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com