High-strength polyimide, preparation method and production equipment

A technology of polyimide and polyimide acid, which is applied in the preparation method and production equipment, can solve the problem that the strength of polyimide cannot meet the demand, and achieve the effect of optimal strength and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

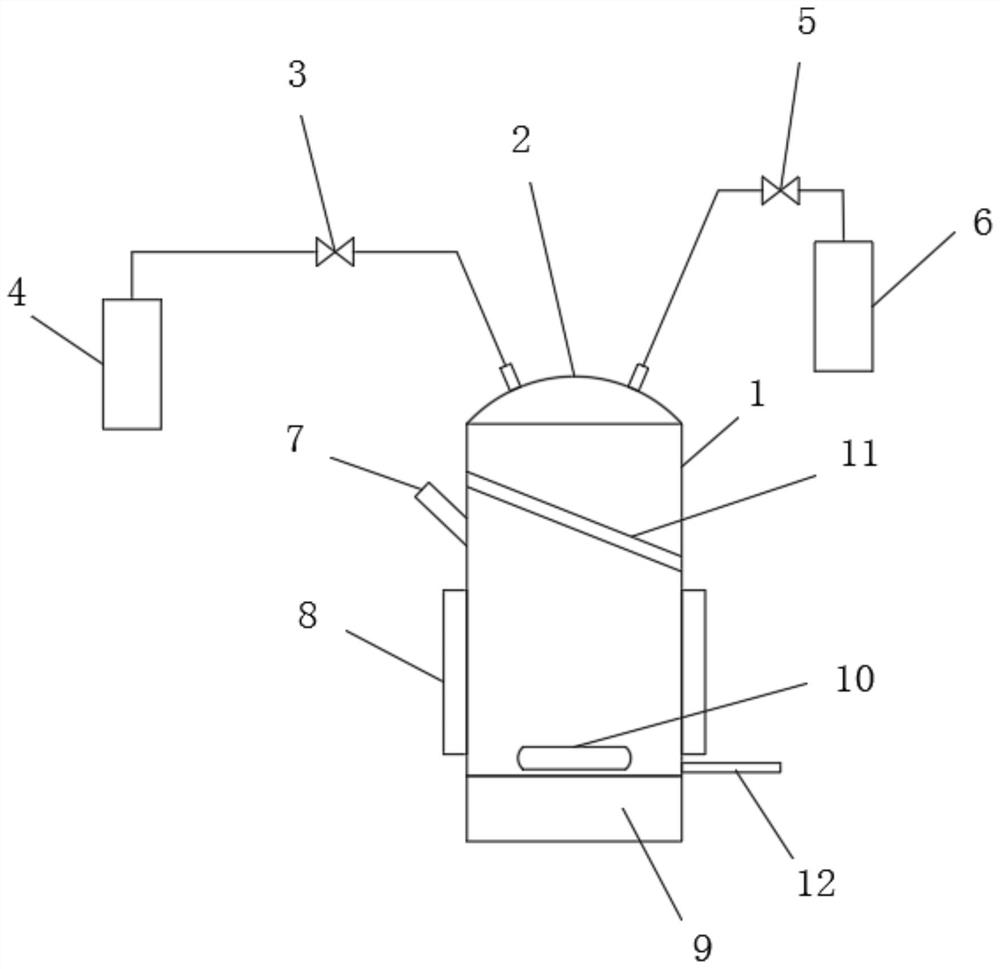

[0024] A method for preparing high-strength polyimide in this embodiment includes the following steps:

[0025] (1) Prepare an organic solvent, in which transparent filaments are dispersedly mixed;

[0026] (2) adding pyromellitic dianhydride and m-toluidine into the organic solvent, and polymerizing the pyromellitic dianhydride and m-toluidine;

[0027] (3) Adding biphenyl tetracarboxylic dianhydride, oxydiphthalic anhydride or benzophenone tetracarboxylic dianhydride to the organic solvent, biphenyl tetracarboxylic dianhydride, oxydiphthalic anhydride or Polymerization of benzophenone tetracarboxylic dianhydride and m-toluidine;

[0028] (4) The polyimide acid generated in the organic solvent is imidized.

[0029] The present invention is further provided as follows: the steps 1-4 are carried out in a nitrogen atmosphere.

[0030] The present invention is further provided as follows: before the imidization of the polyimide acid generated in the organic solvent, the step o...

Embodiment 1

[0040] Start the magnetic stirrer 9, open the solenoid valve 3, and purge the tank 1. Then, 0.1 kg of glass fiber filaments and 1 mol of organic solvent N,N-dimethylformamide were added through the feeding port 7, the heating mantle 8 was turned on, and the temperature in the tank 1 was maintained at 30°C. After that, 1 mol of pyromellitic dianhydride and 2 mol of m-toluidine were added.

[0041] After that, add 1 mol of biphenyl tetracarboxylic dianhydride, oxydiphthalic anhydride or benzophenone tetracarboxylic dianhydride, biphenyl tetracarboxylic dianhydride, oxydiphthalic anhydride or Polymerization of benzophenone tetracarboxylic dianhydride and m-toluidine.

[0042] Since a large amount of nitrogen gas will be mixed in during the feeding and stirring of the magnetic sensor to form bubbles, if the bubbles are not discharged, a loose bubble structure will be formed in the final polyimide product. In order to improve the strength, the bubbles must be discharged. In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com