Method for promoting formation of large aggregates of electrolytic manganese residues

A technology of electrolytic manganese slag and body shape, which is applied in the direction of chemical instruments and methods, fertilizers made of biological waste, applications, etc., can solve problems such as environmental pollution of electrolytic manganese slag piles, increase the number and stability, improve stability, Improve the effect of hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

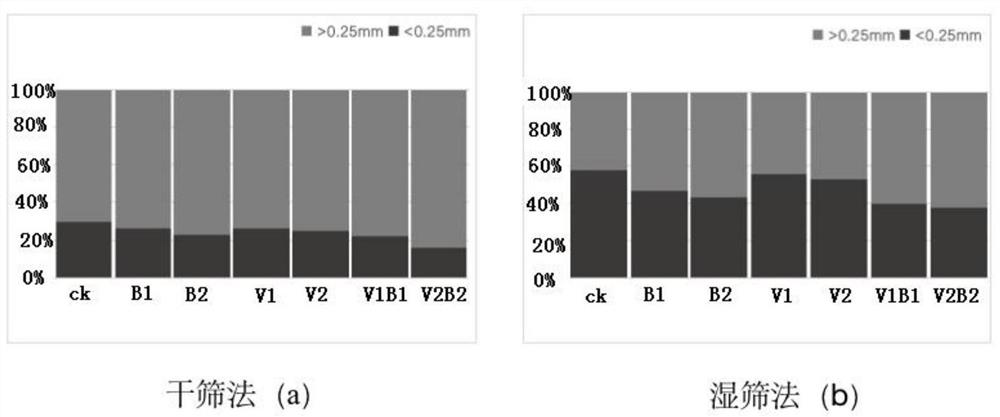

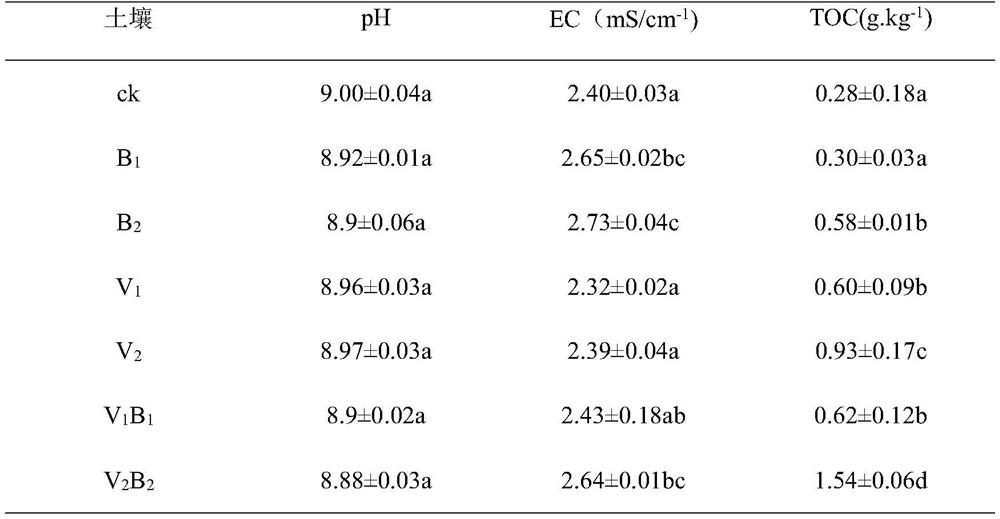

[0027] Changes in the content of large aggregates of electrolytic manganese slag after cultivating in Example 1 for 90 days

[0028] Remove impurities from the electrolytic manganese slag sample, air-dry and pass through a 10-mesh sieve, take 0.5 kg of the sieved sample, add bagasse and earthworm manure in proportion, mix evenly, and then add deionized water to maintain a water holding rate of 70%. Cultivate at room temperature for 90 days to form large aggregates of electrolytic manganese slag.

[0029] V 1 B 1 Group: Vermicompost V 1 20g (4%) and bagasse B 1 20g (4%).

[0030] V 2 B 2 Group: Vermicompost V 2 40g (8%) and bagasse B 2 40g (8%).

Embodiment 2

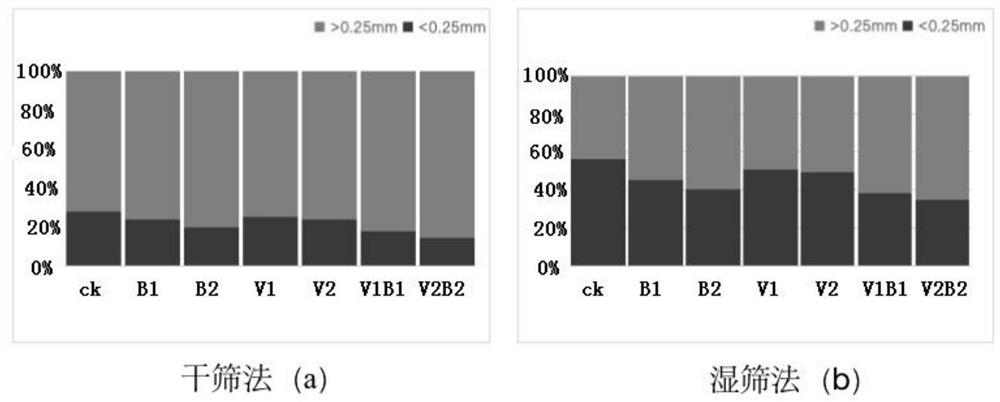

[0045] Changes in the content of large aggregates of electrolytic manganese slag after cultivating in Example 2 for 120 days

[0046] Remove impurities from the electrolytic manganese slag sample, air-dry and pass through a 10-mesh sieve, take 0.5 kg of the sieved sample, add bagasse and earthworm manure in proportion, mix evenly, and then add deionized water to maintain a water holding rate of 70%. Cultivate at room temperature for 120 days to form large aggregates of electrolytic manganese slag.

[0047] V 1 B 1 Group: Vermicompost V 1 20g (4%) and bagasse B 1 20g (4%).

[0048] V 2 B 2 Group: Vermicompost V 2 40g (8%) and bagasse B 2 40g (8%).

Embodiment 3

[0062] Example 3 Remove impurities from the electrolytic manganese slag sample, air-dry and pass through a 10-mesh sieve, take 0.5 kg of the sieved sample, add bagasse B 3 30g (6%) and vermicompost V 3 30g (6%), mixed evenly, then added deionized water to maintain a water holding rate of 70%, and cultivated at room temperature for 120 days to form large aggregates of electrolytic manganese slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com