Industrial purification method of hexamethylenediamine

A purification method and technology of hexamethylenediamine, applied in the direction of amino compound purification/separation, organic chemistry, etc., can solve the problem of high energy consumption for purifying hexamethylenediamine, and achieve the effect of less heat and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

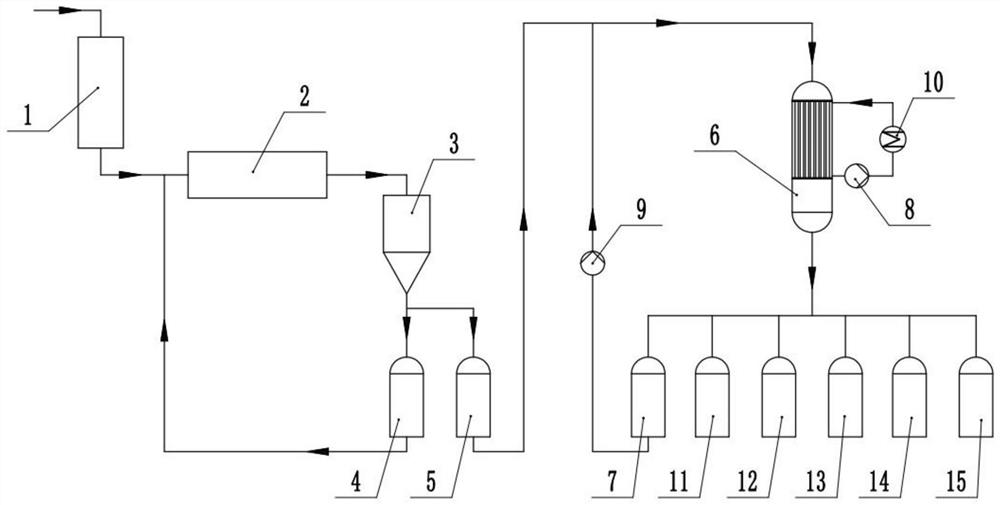

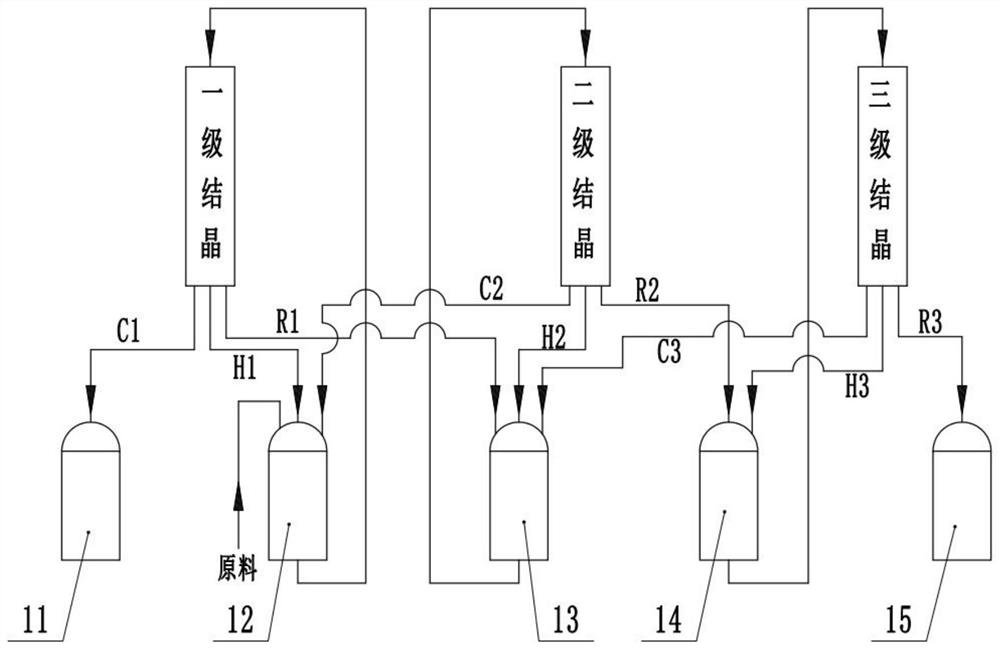

[0053] like figure 1 and figure 2 As shown, this embodiment provides an industrial purification method for hexamethylene diamine, which adopts a three-stage crystallization method in a falling film crystallizer, and specifically includes the following steps:

[0054] Step 1, stirring and evaporation: using stirring evaporator 1, the adiponitrile hydrogenation reaction product (liquid material containing hexamethylene diamine) was stirred and evaporated at 79 ° C for 20 min, and the ethanol in the adiponitrile hydrogenation reaction product was removed. remove.

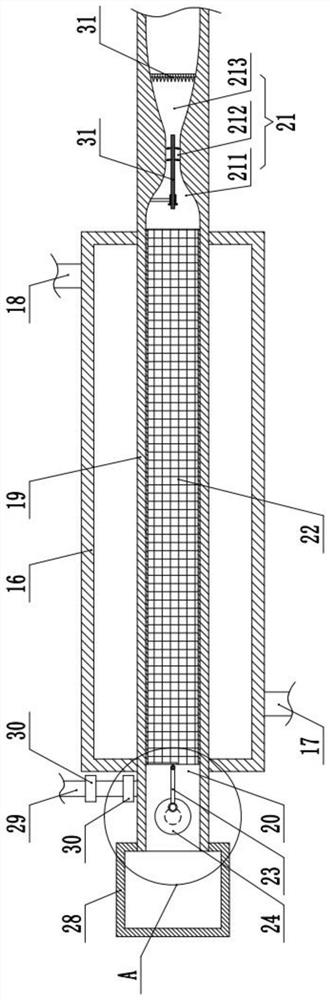

[0055] Step 2: Pre-cooling and crystallization: use the micro-melt crystallizer 2 to carry out pre-cooling and crystallization, combined with image 3 As shown, the micro-melt crystallizer 2 includes a shell 16, and the inner space of the shell 16 is communicated with a cooling and heating medium inlet pipe 17 and a cooling and heating medium outlet pipe 18. The casing 16 is provided with a number of crystalline tu...

Embodiment 2

[0066] The only difference between this example and Example 1 is that this example follows the method of Example 1, and in Step 1, the time for stirring and evaporating is 25 minutes.

[0067] In step 2, the temperature of the cooling and heating medium is reduced at a rate of 15-25°C / h, and the temperature of the liquid material is slowly reduced to 63°C within 38-60 minutes.

[0068] In step three (a), the cooling and heating medium is cooled at a rate of 20-30°C / h, and the liquid material is cooled to 40.5°C within 45-68 minutes; h Raise the temperature of the cooling and heating medium to 42°C, heat for 15 minutes, and keep the cooling and heating medium at 42°C for 15 minutes.

[0069] In step 4, the temperature of the liquid material is slowly reduced to about 40.5°C within 45 minutes, then the temperature of the cooling and heating medium is raised to 42.5°C at 6°C / h, heated for 20 minutes, and the cooling and heating medium is kept at 42.5°C for 15 minutes in circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com