Continuous preparation method of polymer-grade carbohydrate diol

A technique for polymerizing sugars, applied in organic chemistry, etc., can solve the problems of no continuous production technology and method for polymerizing sugar diols, limited application, high price, etc., achieve good application effects, realize industrialization and The effect of large-scale industrial production and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

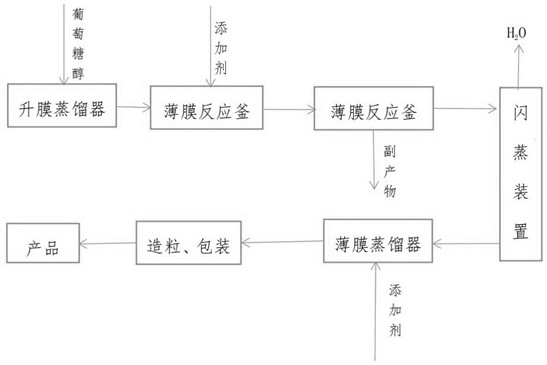

Method used

Image

Examples

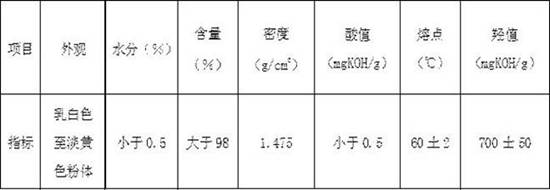

Embodiment 1

[0028] The 70% glucitol is heated to about 80°C through a heat exchanger and continuously enters the rising film evaporation device, removes free moisture at 3000Pa, and then continuously enters the film reactor and continuously adds catalyst phosphoric acid to raise the temperature to 140°C , 1,4-anhydro-D-glucitol and by-product mixture were prepared by circulating at 100-150Pa for two hours, and then continuously entered into the next film reactor device, heated to 185℃, circulated under vacuum 100Pa and collected its light fraction , when the light fraction is no longer distilled, the heavy phase by-product is released, and the light fraction continuously passes through the flash device to remove free water under the vacuum of 1000pa, and then enters the thin film distillation device continuously. The light fraction distilled at a temperature of 180° C. and a vacuum of 100 Pa is 1,4; 3,6-anhydro-D-glucitol, and its content is greater than 98%. Then, it is obtained by cooli...

Embodiment 2

[0030] The 70% glucitol is heated to about 80 ℃ through a heat exchanger and continuously enters the rising film evaporation device, removes free moisture at 3000Pa, and then continuously enters the thin film reactor and continuously adds catalyst sulfuric acid to make the temperature rise to 140 ℃ , 1,4-anhydro-D-glucitol and by-product mixture were prepared by circulating at 100-150Pa for two hours, and then continuously entered into the next film reactor device, heated to 185℃, circulated under vacuum 100Pa and collected its light fraction , when the light fraction is no longer distilled, the heavy phase by-product is released, and the light fraction continuously passes through the flash device to remove free water under the vacuum of 1000pa, and then enters the thin film distillation device continuously. The light fraction distilled at a temperature of 180° C. and a vacuum of 100 Pa is 1,4; 3,6-anhydro-D-glucitol, and its content is greater than 98%. Then, it is obtained b...

Embodiment 3

[0032] The 70% glucitol is heated to about 80 ℃ through a heat exchanger and continuously enters the rising film evaporation device, removes free moisture at 3000Pa, and then continuously enters the film reactor and continuously adds catalyst heteropoly acid to make its temperature rise to 1000Pa. 1,4-anhydro-D-glucitol and by-product mixture were prepared by circulating at 100-150Pa for two hours at 140°C, then continuously entered into the next film reactor device, heated to 185°C, circulated under vacuum 100Pa and collected. Light fraction, when the light fraction is no longer distilled, the heavy phase by-products are released, and the light fraction continuously passes through the flash device to remove free water under vacuum of 1000pa, and then enters the thin film distillation device continuously. The light fraction distilled at a temperature of 180° C. and a vacuum of 100 Pa is 1,4; 3,6-anhydro-D-glucitol, and its content is greater than 98%. Then, it is obtained by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com