Automatic control system and method for drilling blowout prevention

An automatic control and blowout prevention technology, applied in earthwork drilling, borehole/well valve device, measurement, etc., can solve problems such as system complexity, achieve simple and convenient operation, avoid gas overrun, speed up and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

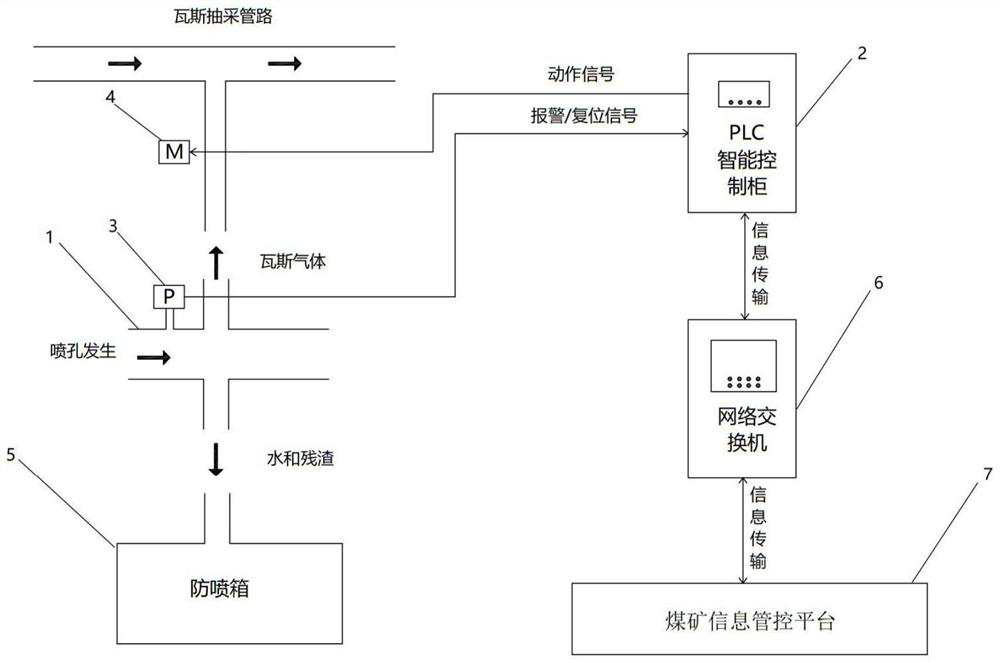

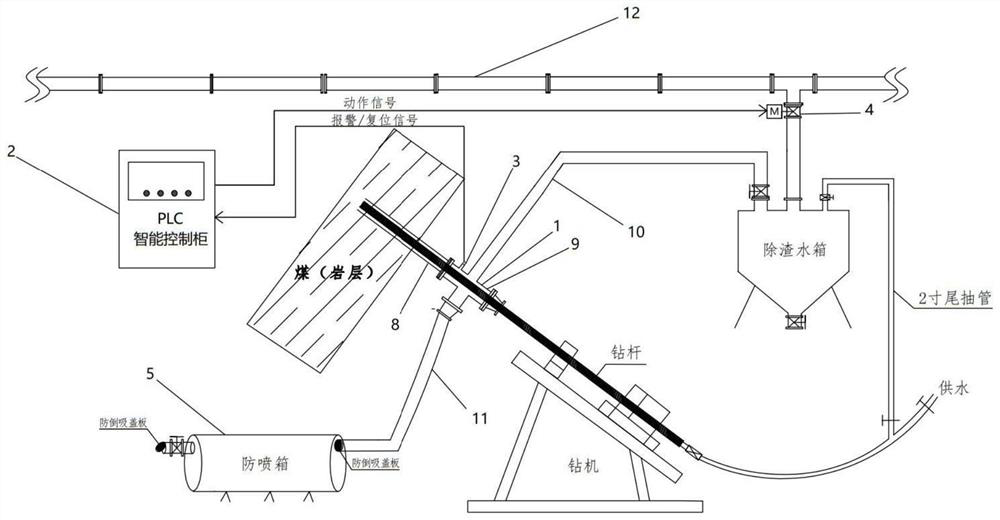

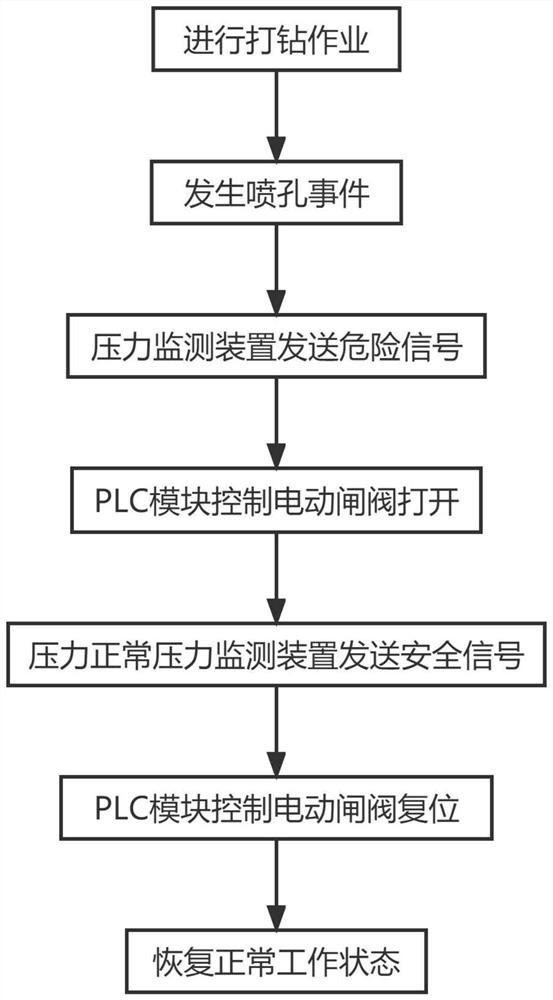

[0020] Below in conjunction with accompanying drawing, one embodiment of the present invention is further described:

[0021] The drilling blowout prevention automatic control system of the present invention includes a slag removal water tank, a blowout prevention box, a drilling rig, a PLC intelligent control cabinet 2, a network switch 6 and a coal mine information management and control platform 7, and an orifice blowout prevention is set at the selected drilling position. Device 1, the orifice blowout preventer 1 includes a spool 9 and an orifice casing 8 connected to the spool 9 whose front orifice extends into the coal formation, and the rear orifice of the spool 9 There is a drill pipe that passes through the orifice casing 8 from the spool 9 and enters the coal rock layer. The nozzle is connected with an upper suction pipe 10 for discharging gas; a pressure sensor 3 connected to the PLC intelligent control cabinet 2 by wires is provided at the connection of the four-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com