Hydropower station hydraulic hoist hydraulic oil quality online guarantee system and control method thereof

A hydraulic hoist and hydraulic oil technology, applied in the direction of liquid level control, non-electric variable control, fluid pressure actuation system components, etc., can solve the problem of not being able to detect signs of oil deterioration in time and equipment that does not have the function of emergency oil replenishment , The hydraulic hoist system cannot work and other problems, to achieve the effect of ensuring safe, stable and efficient operation, stable and reliable uninterrupted operation, and shortening the time for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

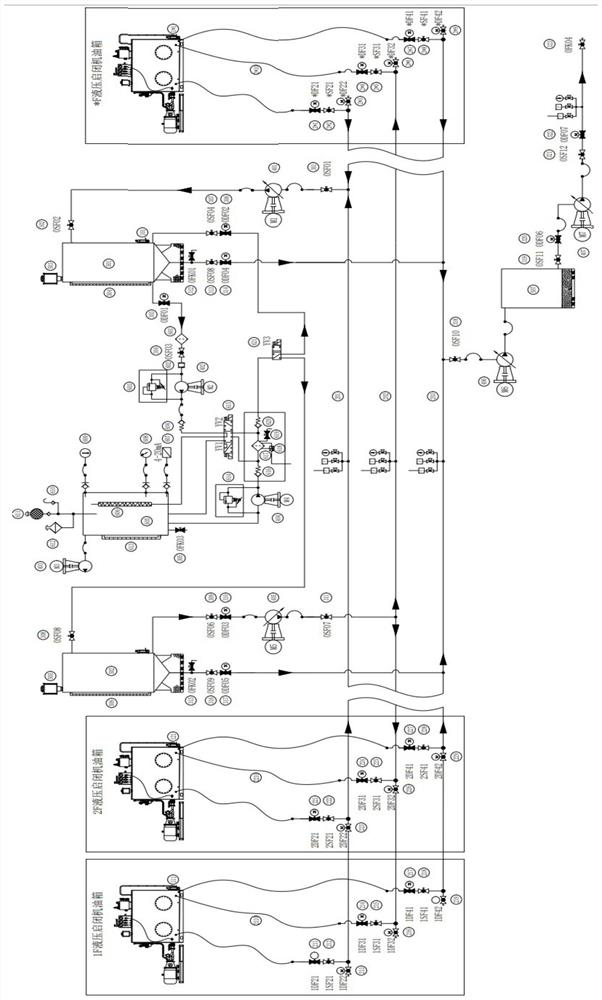

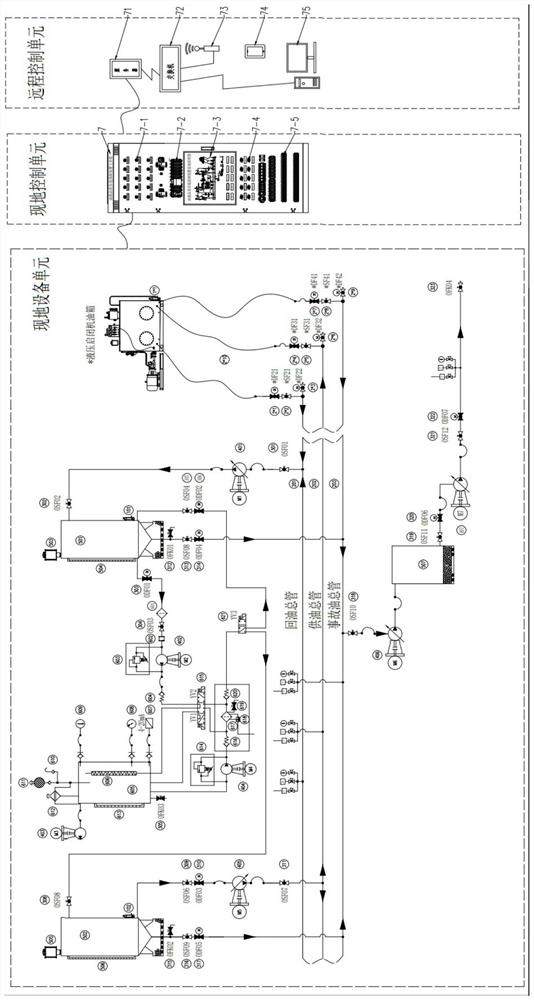

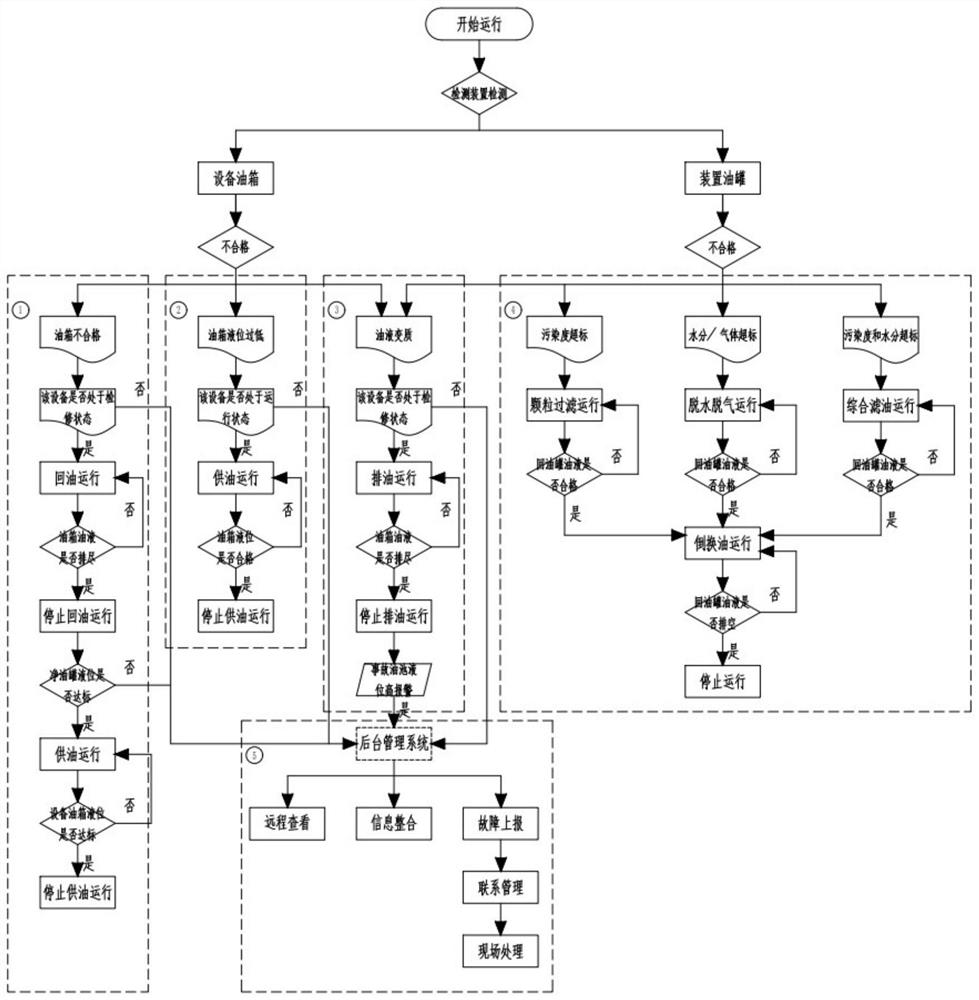

[0044] See attached figure 1 , as an embodiment of the present invention, an online quality assurance system for hydraulic oil of hydraulic hoists for hydropower stations is proposed, which includes an oil return header 201, an oil supply header 202 and an accident oil header 203, an oil return header 201, an oil supply header The main pipe 202 and the accident oil main pipe 203 are connected to the oil tank of the hydraulic hoist through the pressure hose 2*10, which can be arranged and installed on the side wall of the channel along the operating equipment. Each hoist to be tested is installed according to the location of the field equipment. Valves 2*1-2*9 and 3 quick-connection hoses 2*10, realize the device can be quickly connected with the existing operating equipment, and achieve the universality of the device of the present invention; the accident oil main pipe 203 and the accident oil pool 507 The accident oil pump 407 is connected to the pipeline between the accident...

Embodiment 2

[0048] See attached figure 1 -Attached image 3 , as a preferred embodiment of the present invention, on the basis of Embodiment 1, the oil filter system includes a particle filter unit and a water vapor filter unit, and the particle filter unit includes a discharge pump 404 connected to the rear end of the suction pump 402 and a discharge pump 404 connected to the discharge The particle filter 617 at the rear end of the pump 404, the inlet of the particle filter 617 is connected to the particle filter inlet check valve 616, and the outlet is connected to the particle filter outlet check valve 620 and the particle filter outlet venting ball valve 619, where the particle filter 617 is located A differential pressure transmitter 618 is installed on the pipeline to monitor the pressure difference between the front and rear ends of the particulate filter 617; the outlet of the oil suction pump 402 is connected to the inlet of the three-position five-way reversing valve 615, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com