Mine water suspended matter treatment device, working method and treatment method

A treatment device and suspended solids technology, which is applied in the field of mine water suspended solids treatment and mine water suspended solids treatment equipment, can solve the problems of large equipment footprint and high treatment costs, and achieve reduced investment costs, reduced investment and production costs, The effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

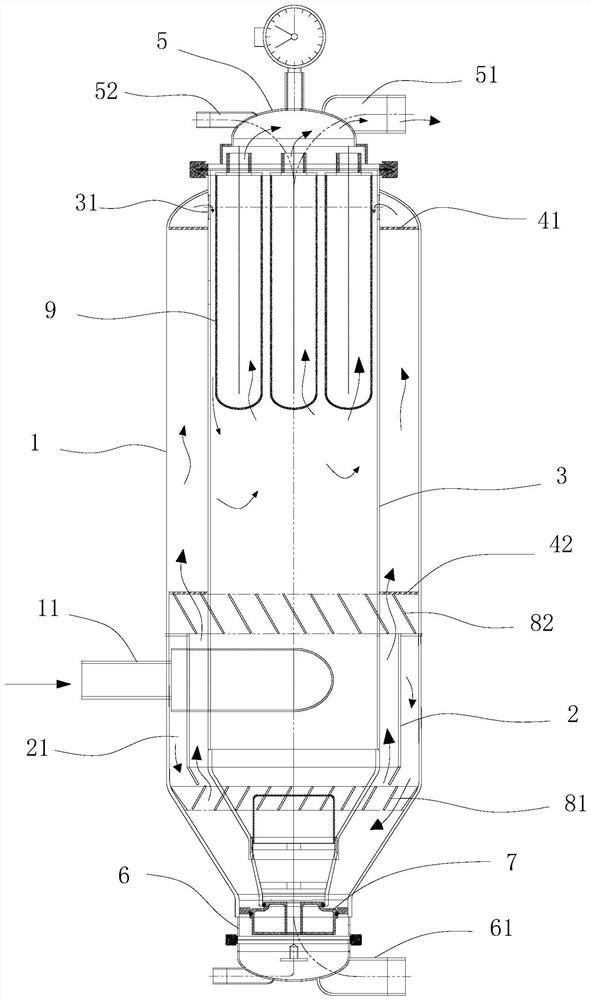

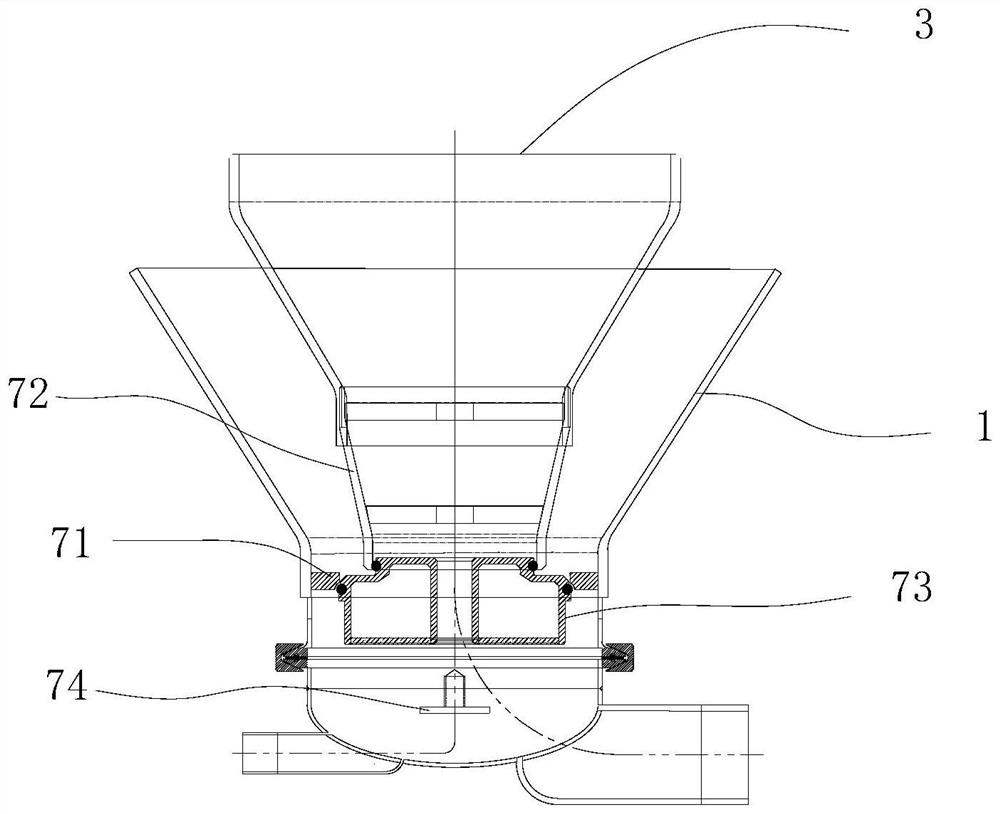

[0058] like figure 1 figure 2 As shown, a mine water suspended solids treatment device, comprising:

[0059] The outer cylinder 1 has a first outlet at its lower end, and its side wall is connected to a water inlet pipe 11;

[0060] The cyclone separation cylinder 2 is located in the outer cylinder 1, and its upper end is fixedly connected with the inner wall of the outer cylinder 1; a cyclone separation cavity 21 is formed between the outer wall of the cyclone 2 and the inner wall of the outer cylinder 1. The lower end of the flow separation cavity 21 is communicated with the inner cavity of the outer cylinder 1;

[0061] The lower end of the inner cylinder 3 is inserted from the upper end of the outer cylinder 1, the lower end of the inner cylinder 3 is provided with a second outlet, a compartment is formed between the inner cylinder 3 and the outer cylinder 1, and the lower end of the compartment is connected to the outer cylinder 1. The inner cavity of the outer cylind...

Embodiment 2

[0094] Provide a working method using the mine water suspended solids treatment device of the first embodiment, comprising:

[0095] The clean water suction pipe 51 is connected to the negative pressure pump, so that negative pressure is formed in the inner cylinder 3 and the outer cylinder 1;

[0096] After the mine mud water enters from the water inlet pipe 11 , it is filtered through the cyclone separation chamber 21 , the filter ball assembly and the membrane assembly in sequence, and then sucked away by the clean water suction pipe 51 .

[0097] Specifically, the water inlet pipe 11 and the clean water suction pipe 51 are closed, and the sludge discharge pipe 61 forms a certain opening;

[0098] Compressed air is introduced from the blowback air pipe 52 for 2-3 seconds to drive the foam filter balls in the inner cylinder 3 to move up and down, so that the foam filter balls scrub the outer wall of the membrane filter rod 9 .

Embodiment 3

[0100] A method for treating suspended solids in mine water is provided, using the device for treating suspended solids in mine water in Embodiment 1, comprising the following steps:

[0101] Step S01, the clear water pumping pipe 51 is connected to the negative pressure pump, so that the chambers in the inner cylinder body 3 and the outer cylinder body 1 are all under negative pressure, and the mine muddy water is drawn into the outer cylinder body 1 through the water inlet pipe 11; The separation is carried out through the cyclone separation chamber 21;

[0102] In step S02, the separated mine mud water enters the compartment, and the mine mud water enters the inner cylinder 3 after being filtered by the filter ball assembly in the compartment;

[0103] In step S03 , the mine muddy water is filtered by the membrane module and then enters the upper cover 5 , and is finally pumped away by the clean water suction pipe 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com