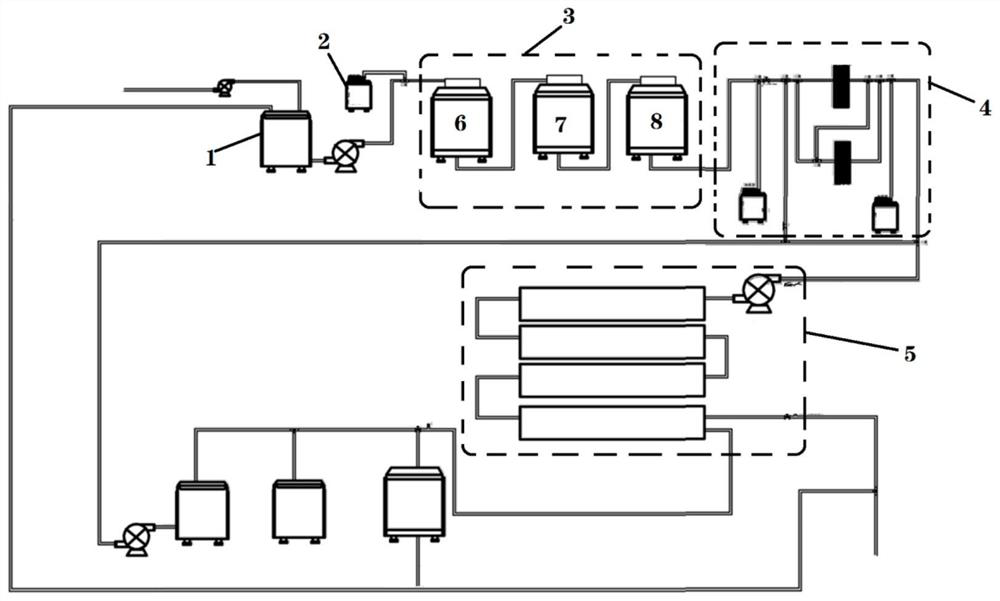

Reverse osmosis recycling method and device for hydrochloric acid well washing waste liquid of uranium mine

A technology of hydrochloric pickling and reverse osmosis, applied in mining wastewater treatment, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the problem of no mature products and achieve the effect of reducing turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] A uranium mine hydrochloric acid well washing waste liquid reverse osmosis recycling method, comprising the following steps:

[0057] Step 1: pH Adjustment

[0058] The pH value of the waste liquid needs to be controlled within the range of 6.5-8.

[0059] The specific operation steps are as follows: Use 15m 3 After the tank is filled with clean water, 400Kg of caustic soda (NaOH) is added; after 1 hour of uninterrupted stirring, its pH value can reach above 12. Use a pressure pump to pump the well-stirred flake alkali solution into the well washing waste liquid pool (1200m 3 ). In order to make the acid-base neutralization reaction between the well washing waste liquid and the flake alkali solution fully, the air compressor is used to blow the well washing waste liquid pool.

[0060] The air blowing time is 24 hours. After 24 hours, the pH value of the waste liquid is detected. If the pH value reaches the preset value, the air blowing is stopped; if the pH value is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com