Silicon oxide film forming machine for preparing automatic alternating type solar cell

A technology for solar cells and silicon oxide films, which is applied in the field of solar cells, can solve the problems of lowering production efficiency, affecting the full reaction between silicon wafers and reaction solution, and taking time to achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

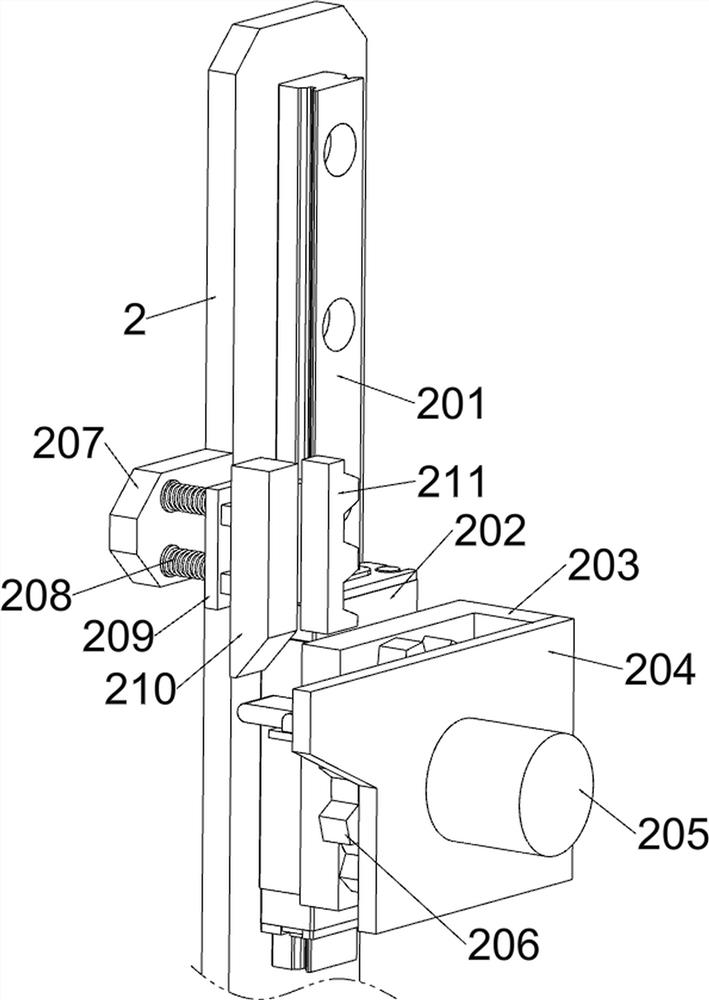

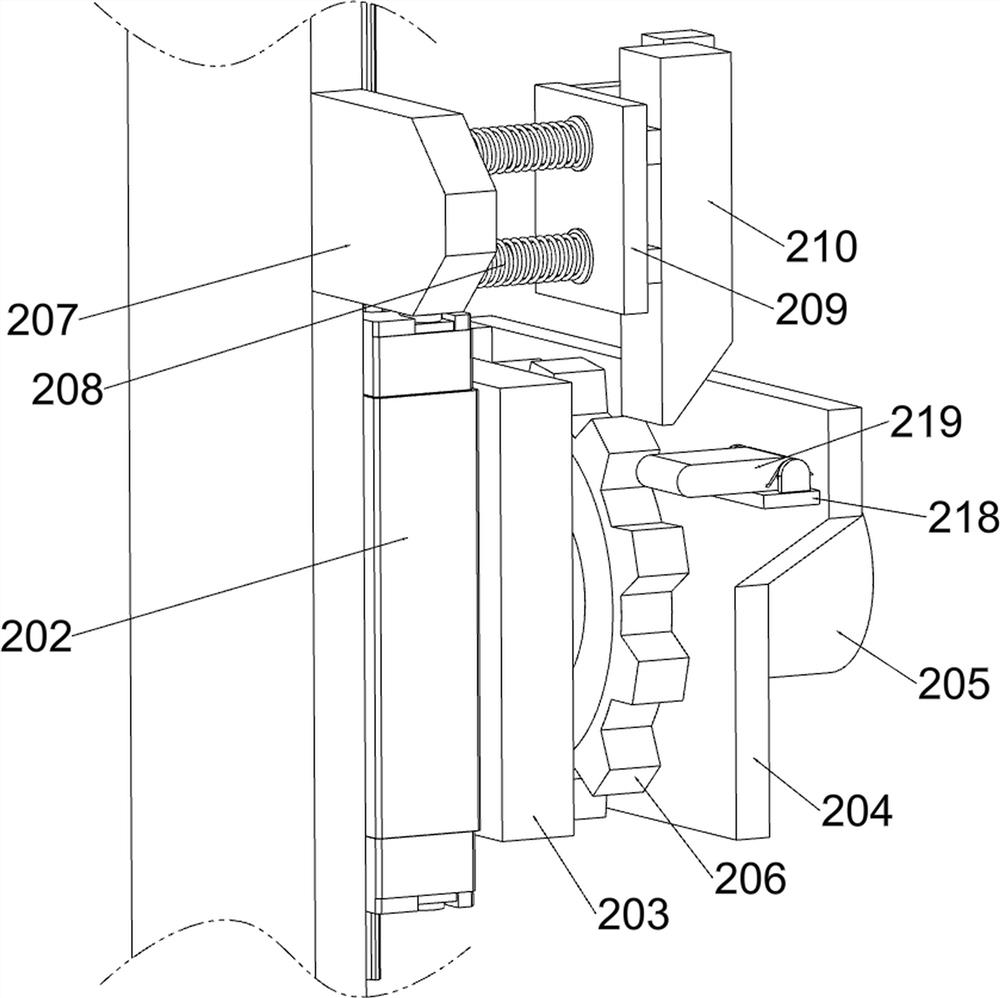

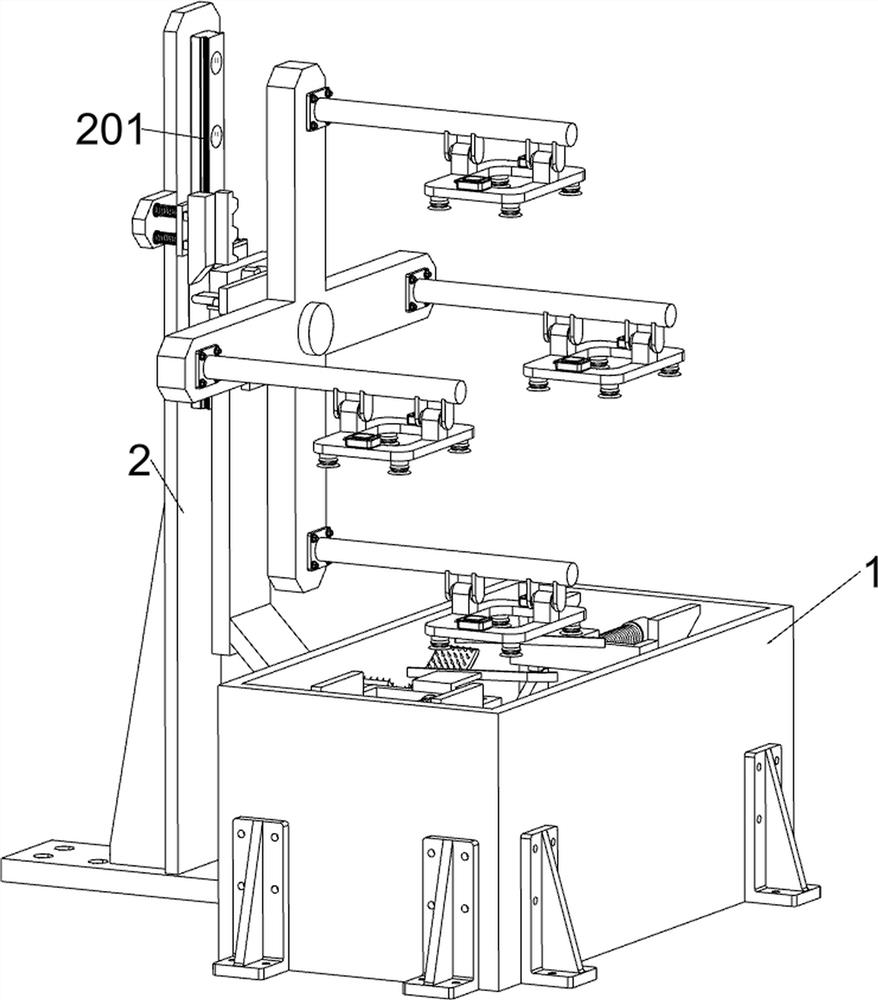

[0028] An automatic rotation type silicon oxide film forming machine for solar cell preparation, such as Figure 1-8 As shown, it includes a reaction box 1, a support frame 2, an ultraviolet lamp 3, an isolation cover 4, a rotating feeding system and a bubble dispersing system; the left side of the reaction box 1 is provided with a support frame 2; the inner bottom wall of the reaction box 1 is connected by bolts There is an ultraviolet lamp 3; the inner bottom wall of the reaction box 1 is fixedly connected with an isolation cover 4; the ultraviolet lamp 3 is located in the isolation cover 4; the right side of the support frame 2 is connected with a rotating feeding system; .

[0029] The isolation cover 4 is made of transparent material.

[0030]When using the automatic rotation type silicon oxide film forming machine for solar cell preparation, the reaction box 1 and the support frame 2 are installed at the required positions, and a sufficient amount of titanium dioxide aq...

Embodiment 2

[0043] On the basis of Example 1, as Figure 1-2 and Image 6 As shown, it also includes a stirring system; the reaction box 1 is connected with a stirring system; the lower side of the L-shaped plate 203 is connected with the stirring system; the stirring system includes a third fixing plate 401, a fourth fixing plate 402, and a fifth fixing plate 403 , the second gear tooth plate 404, the second connecting shaft 405, the second flat gear 406 and the stirring roller 407; the lower side of the L-shaped plate 203 is fixedly connected with a third fixing plate 401; the lower part of the right side of the third fixing plate 401 is fixedly connected with a A fourth fixing plate 402; a fifth fixing plate 403 is fixedly connected to the lower part of the right side of the fourth fixing plate 402; A second connecting shaft 405 is rotatably connected to the front and the inner rear; the left parts of the two second connecting shafts 405 are each fixedly connected with a second spur g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com