Kitchen garbage treatment and resource utilization method and system

A kitchen waste recycling technology, applied in biochemical equipment and methods, biomass post-treatment, biomass pre-treatment, etc., can solve the problems of large loss, complicated process, and increased project investment and operating costs of treatment plants , to achieve high resource utilization, uniform pulp quality, and continuous pyrolysis production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The materials, reagents or equipment used in the following examples, unless otherwise specified, can be obtained from commercial channels or existing technologies, and will not be repeated herein.

[0076] After the kitchen waste is treated by thermal hydrolysis, the organic matter in the waste is dissolved and dissolved, killing the microorganisms and eggs on the surface of the kitchen waste. While completing the harmlessness and reduction of the kitchen waste, anaerobic fermentation can be carried out. Realize the recycling of kitchen waste.

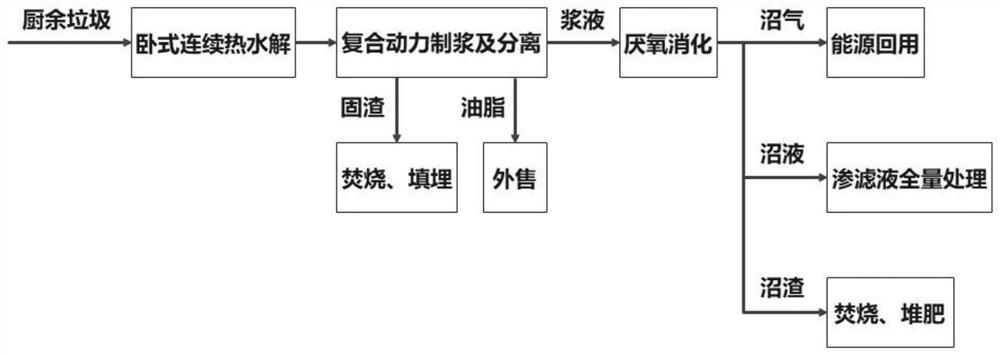

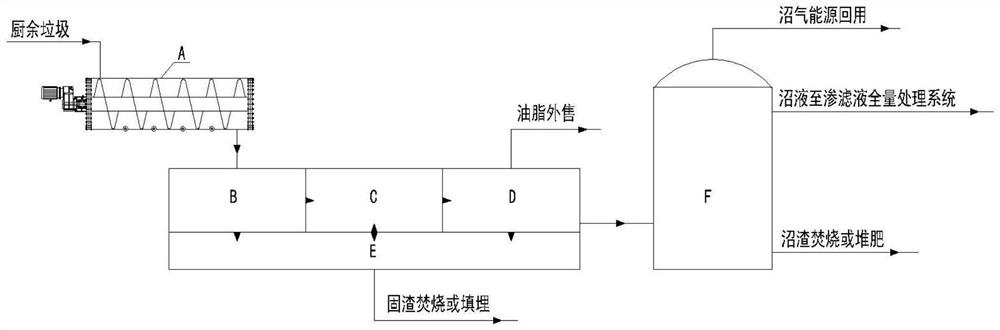

[0077] When the incoming kitchen waste is mainly food residues generated in residents' lives or mixed with some kitchen wastes, the content of oil and fat in the waste components is high, and it needs to be processed by the oil extraction process to avoid subsequent anaerobic digestion and leachate treatment. adversely affect the system. like figure 1 As shown, the process steps are as follows:

[0078] 1) The kitchen waste i...

Embodiment 2

[0088] When the incoming kitchen waste is mainly fruit and vegetable waste from the farmers market, the oil content in the waste is low, and there is no need to increase the oil extraction process. The process steps are as follows:

[0089] 1) The kitchen waste is thermally hydrolyzed at high temperature in the horizontal continuous thermal hydrolysis system to kill the microorganisms and eggs on the surface of the kitchen waste and destroy the tissue structure of some substances in the waste;

[0090] 2) The composite dynamic pulping system crushes and separates the hydrolyzed clinker, and mixes it through hydraulic shearing and mechanical stirring to form a homogenized slurry. The separated kitchen waste solid slag, plastic products, glass products and metals and other impurities enter the solid liquid separation system;

[0091] 3) The homogenized slurry enters the sand and impurity removal system to remove impurities such as sand, glass and shells;

[0092] 4) The filtrat...

Embodiment 3

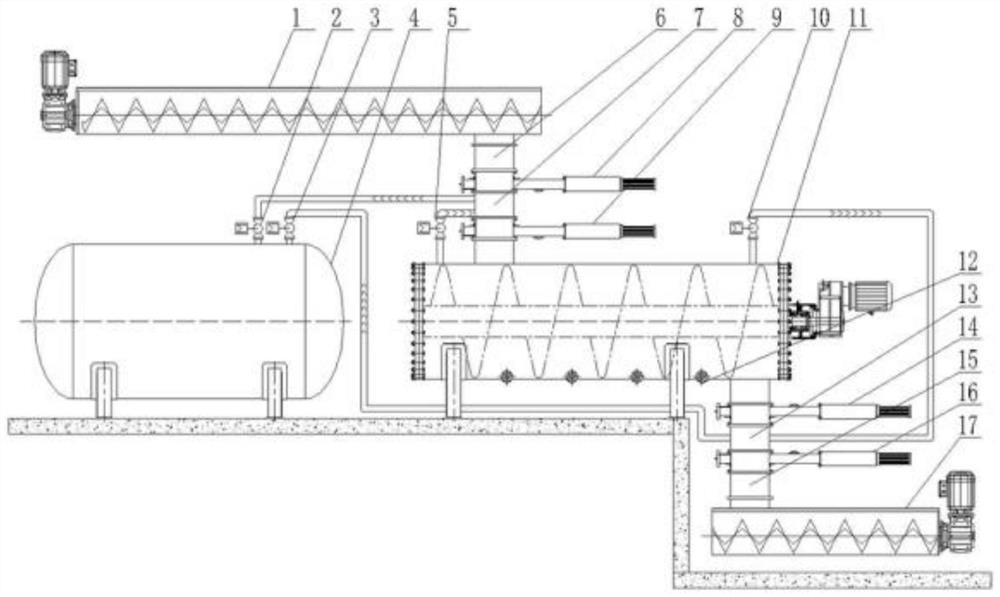

[0098] example image 3 As shown, a kitchen waste continuous thermal hydrolysis system A provided in this embodiment includes a feed conveyor 1, a feed storage section 6, a feed balance section 7, a horizontal thermal hydrolysis tank 11, The discharge balance section 13, the discharge storage section 15, the discharge conveyor 17 and the balance tank 4.

[0099] A screw conveying device is provided inside the horizontal thermal hydrolysis tank 11 . The top of the horizontal thermal hydrolysis tank 11 is provided with a feed port and a communication port communicating with the feed storage section 6 and the feed balance section 7 . The bottom of the horizontal thermal hydrolysis tank 11 is provided with several discharge ports and steam inlets 12 . The conveying channel from the feed conveyor 1 to the feed port of the horizontal thermal hydrolysis tank 11 is provided with a feed storage section 6 and a feed balance section 7; the discharge conveyor 17 to the discharge port of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com