Cold rolling method for improving comprehensive performance of BCC structure corrosion-resistant alloy sheet

A corrosion-resistant alloy with comprehensive performance technology, applied in the field of iron and steel alloy materials, can solve the problems that the process method is difficult to achieve large-scale industrial application, it is difficult to apply non-phase transformation type BCC structure corrosion-resistant alloy, and the degree of performance improvement is low, reaching The average wrinkle height is reduced, the requirements for production equipment are not high, and the plastic strain ratio is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Smelting and casting according to the set composition to make an ingot, the composition of the ingot contains C 0.0099%, N 0.0094%, Cr 25.2%, Zr 0.28%, V 0.07%, Si 0.14%, Mn 0.07% according to the mass percentage , the balance is Fe and inevitable impurities; the ingot contains P 0.02%, S 0.001%, O 0.003% by mass percentage;

[0041] (2) The hot-rolled ingot is cooled to room temperature to make a hot-rolled sheet; the hot-rolled sheet is annealed to make a hot-rolled annealed sheet; hot rolling is to heat the ingot to 1200±30°C for 150 minutes, and then The rolling was started at 1100°C, and the final rolling temperature was 850°C; the reduction ratio of hot rolling was 97%; 0 =6mm;

[0042] (3) carrying out the first stage cold rolling of the hot-rolled and annealed sheet to make the first cold-rolled sheet;

[0043] (4) The first cold-rolled sheet is subjected to intermediate annealing, and then the second-stage cold-rolling is performed to make the second cold...

Embodiment 2

[0052] The method is the same as in Example 1, except that:

[0053] In the two-stage cold rolling process, the distribution coefficient of cold rolling reduction in different stages is n=0.3, where n=(2.43–0.9) / (6–0.9);

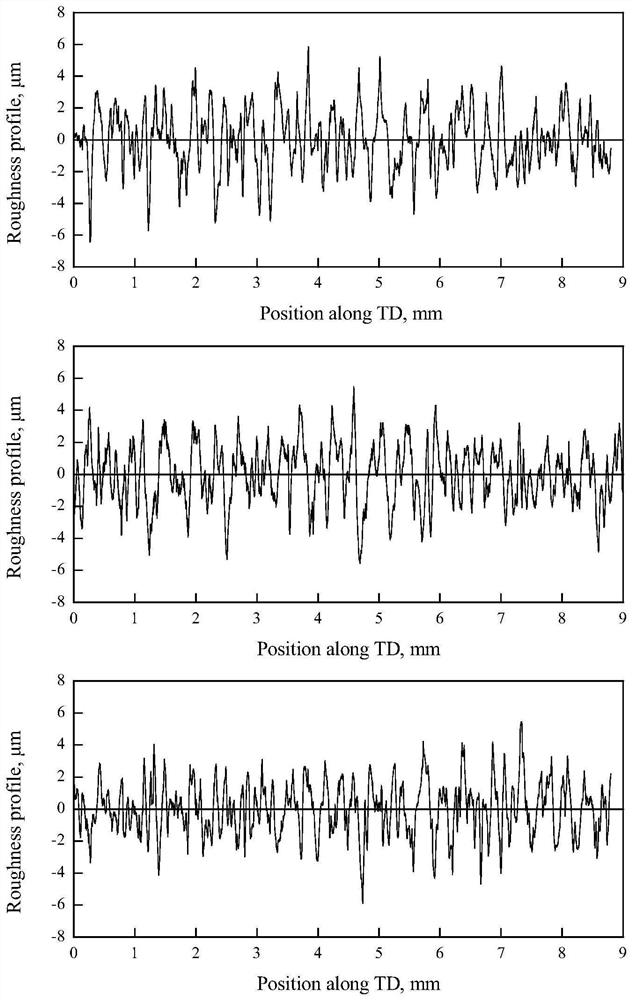

[0054] After testing, the average r value of the finished board is 2.26, the anisotropy parameter Δr is 0.21, and the average wrinkle height is 11.05 μm; the surface morphology photo of the finished board after 15% tensile deformation is as follows figure 1 As shown in the middle picture; the roughness curve of the finished plate after 15% tensile deformation is as follows figure 2 shown in the middle picture.

Embodiment 3

[0056] The method is the same as in Example 1, except that:

[0057] The total reduction ratio of the first-stage cold rolling and the second-stage cold rolling is 90%; in the two-stage cold rolling process, the distribution coefficient of cold rolling reduction in different stages is n=0.45, where n=(3.03–0.6 ) / (6–0.6);

[0058] After testing, the average r value of the finished board is 2.35, the anisotropy parameter Δr is 0.3, and the average wrinkle height is 11.34 μm; the surface morphology photo of the finished board after 15% tensile deformation is as follows figure 1 As shown in the figure below; the roughness curve of the finished plate after 15% tensile deformation is as follows figure 2 as shown below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com