Anti-corrosion treatment equipment in water conservancy project and working method of anti-corrosion treatment equipment

A technology for anti-corrosion treatment and water conservancy engineering. It is used in mechanical equipment, pipeline anti-corrosion/rust protection, damage protection, etc. It can solve problems such as difficulty in mechanical automatic brushing, aggravating the corrosion degree of metal water conservancy pipelines, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

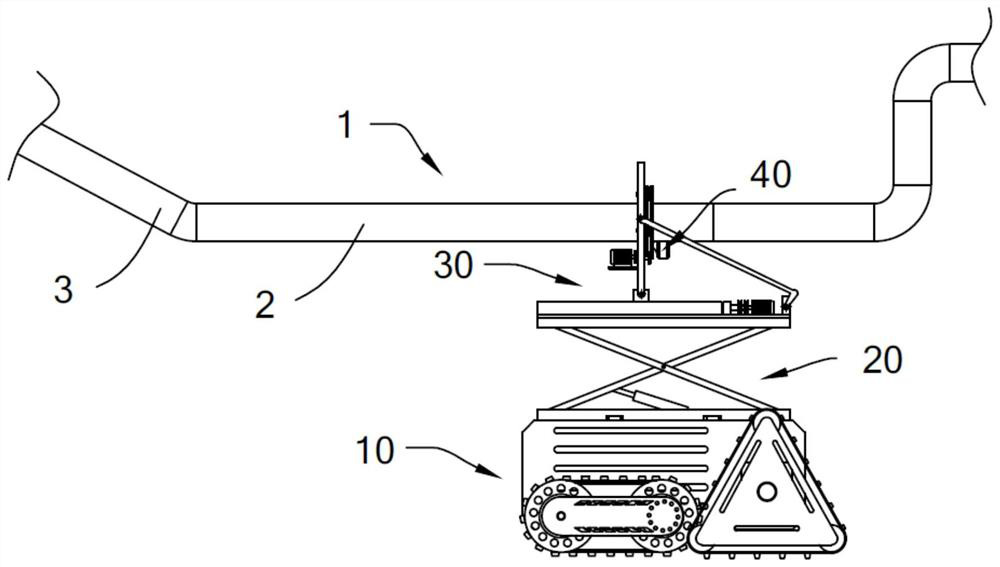

[0035] like Figure 1 to Figure 4 As shown, the present invention provides an anti-corrosion treatment equipment in a water conservancy project, including a moving vehicle 10 , a lifting assembly 20 , a dipping assembly 30 and a brushing unit 40 .

[0036] The lifting assembly 20 is arranged on the moving vehicle 10;

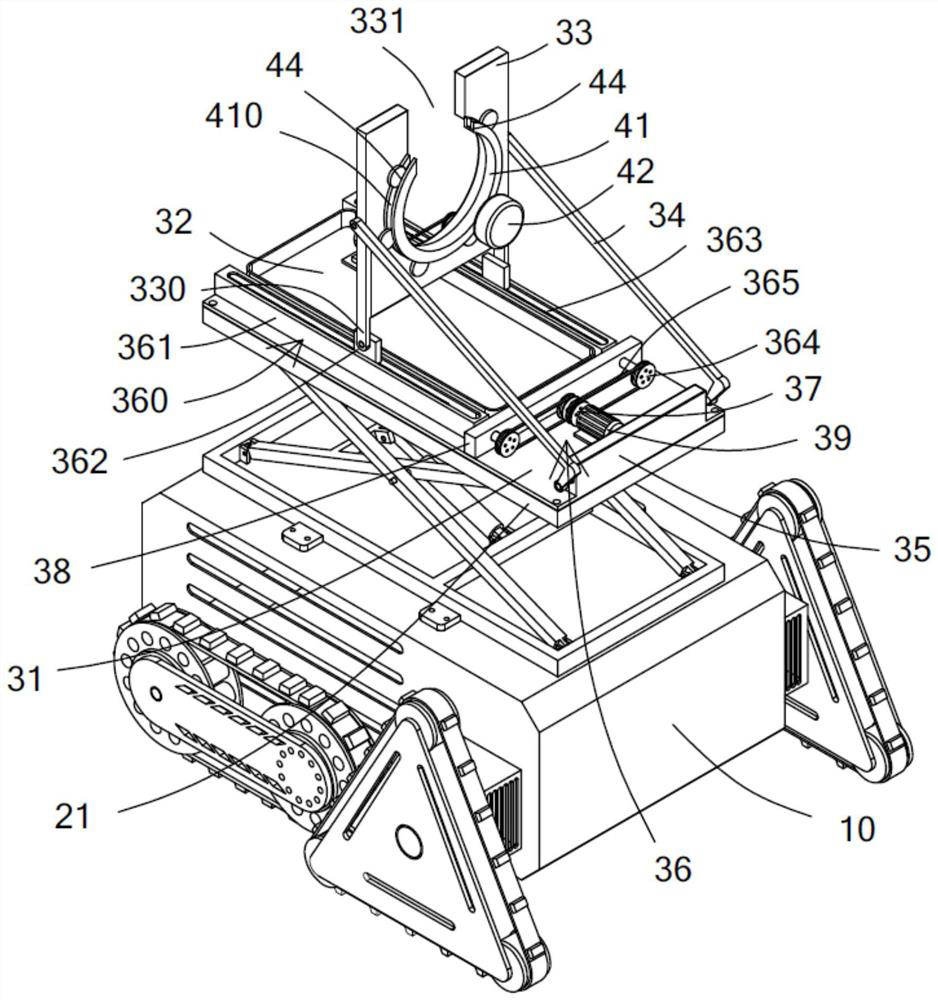

[0037] The dip assembly 30 includes a base plate 31, a dip frame 32, a flip plate 33, an L-shaped hinge rod 34, a mounting plate 35 and a drive unit 36. The base plate 31 is fixedly connected to the top of the lifting assembly 20, and the dip frame 32 is fixedly arranged on the base plate. 31, the mounting plate 35 is fixedly arranged on the base plate 31, and the mounting plate 35 is located at the front end of the dipping frame 32, the number of L-shaped hinge rods 34 is two, and one end of the two L-shaped hinge rods 34 is respectively connected with the mounting plate 35. Hinged, the other ends of the two L-shaped hinge rods 34 are hinged to the center positi...

no. 2 example

[0051] The driving unit 36 includes a driving member 360, a driving wheel 37, a fixed plate 38 and a turning motor 39. The number of the driving members 360 is two. 364 and the conveyor belt 365, the two slideways 361 are fixedly arranged on the base plate 31, and the two slideways 361 are located on both sides of the dip frame 32, the mounting plate 35 is fixedly connected to the base plate 31, and the fixing plate 38 is located on the mounting plate 35 and the dipping frame 32, a lead screw 363 is arranged in the slideway 361 to rotate along its length direction, a slide block 362 is sleeved on the lead screw 363, the slide block 362 is hinged with the extension plate 330, and one end of the lead screw 363 is One end is fixedly connected, and the other end of the rotating shaft is fixedly connected to the driven wheel 364 through the fixed plate 38. The driven wheel 364 is connected to the driving wheel 37 through the conveyor belt 365. On the output shaft of the inversion...

no. 3 example

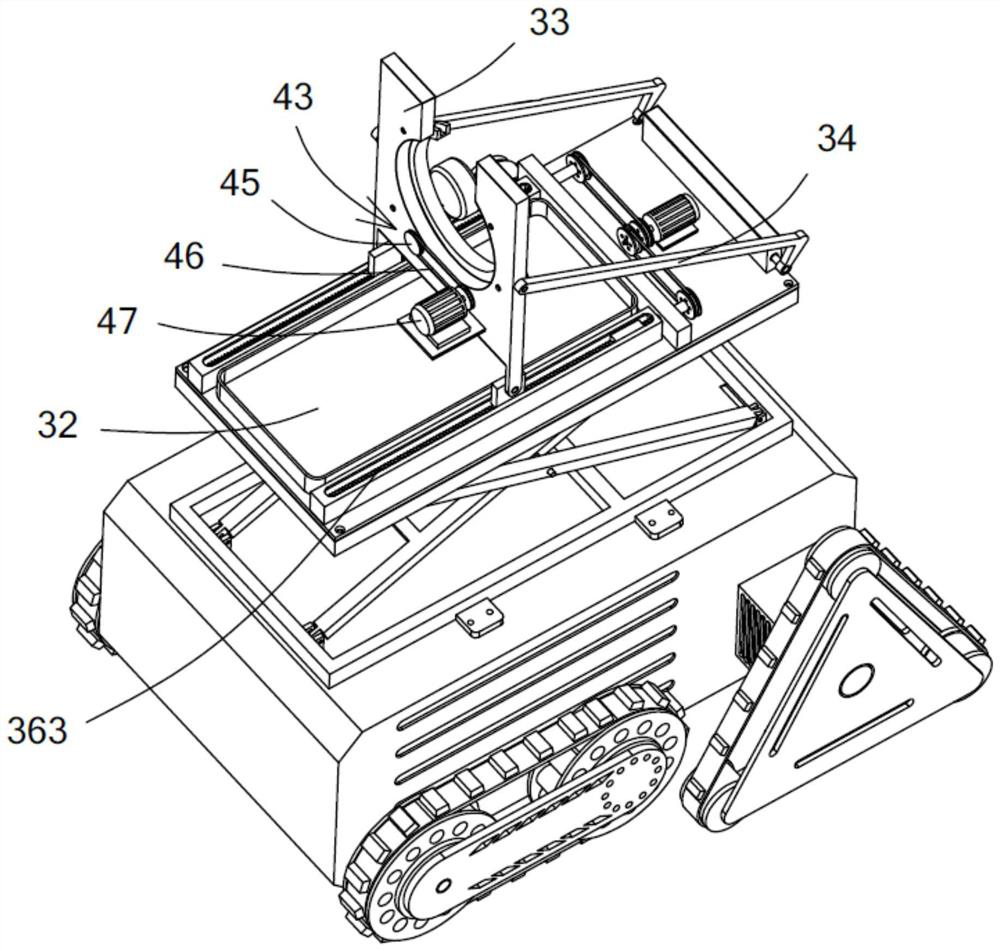

[0056] The brushing unit 40 also includes a transmission member 43, the transmission member 43 is used to drive the wheel frame 41 to rotate, the wheel frame 41 is a ring body, the outer ring wall of the ring body is provided with a guide groove 410, the ring body is provided with a second notch 44, and the transmission member 43 It includes a limit wheel 44, a transmission wheel 45, a transmission belt 46 and a transmission motor 47. There are multiple limit wheels 44, and the plurality of limit wheels 44 are rotated and arranged on one side wall of the flap 33. The number of the drive wheels 45 is two. The rotation of the two transmission wheels 45 is arranged on the other side wall of the flap 33 , and the two transmission wheels 45 are respectively linked with the two adjacent limit wheels 44 , and the transmission belt 46 is sleeved on the two transmission wheels 45 . , the output shaft of the transmission motor 47 is fixedly connected with any transmission wheel 45 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com