Method and system for detecting punching forming of lead frame plastic package integrated circuit

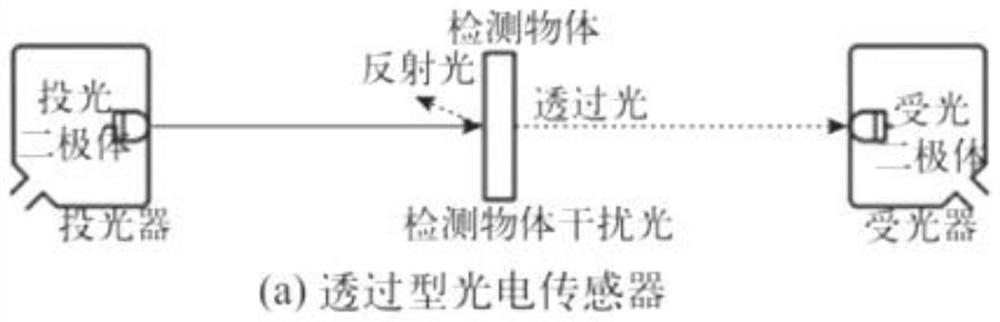

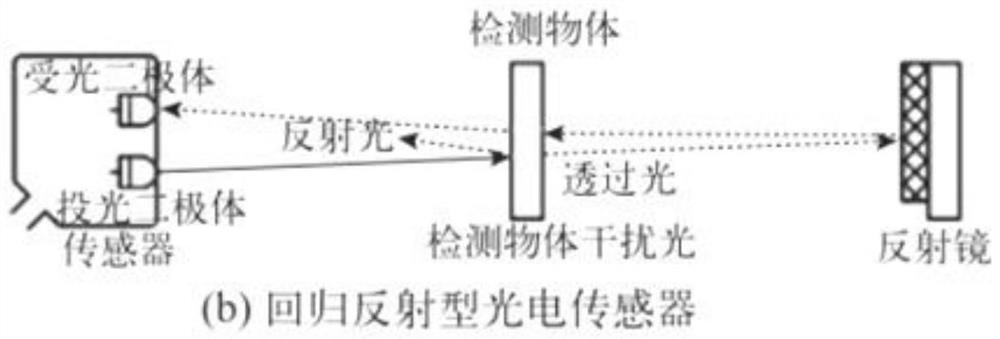

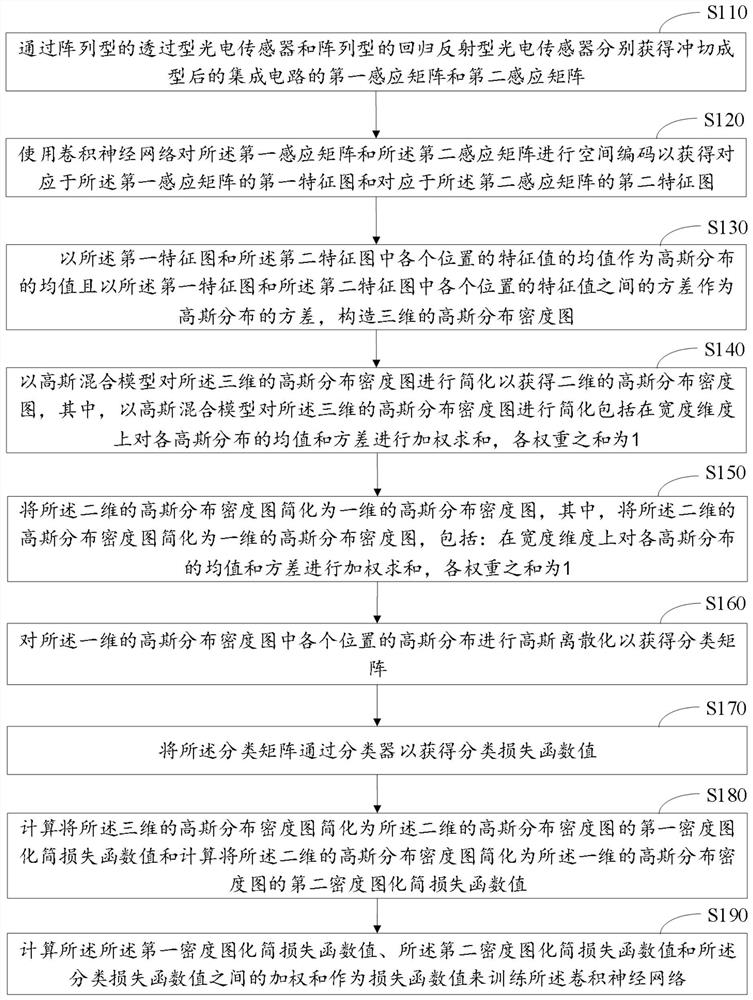

A technology for integrated circuits and lead frames, which is applied in the field of detection methods and systems for die-cutting and forming of plastic-encapsulated integrated circuits in lead frames, and can solve problems such as low accuracy, damage to connecting ribs, and high difficulty in detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, exemplary embodiments according to the present application will be described in detail with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present application, rather than all the embodiments of the present application, and it should be understood that the present application is not limited by the example embodiments described herein.

[0034] Scenario overview

[0035] As mentioned above, in the process of punching and forming the leads of the lead frame plastic-encapsulated integrated circuit, there will be abnormal phenomena such as the rupture of the plastic body and the breakage of the pins. Relevant molding die damage. However, in the current inspection process, since the surface of the plastic package is not only inspected, the inspection is difficult and the accuracy is low. In order to better detect these abnormalities, to protect the equipment and ensure the yield of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com