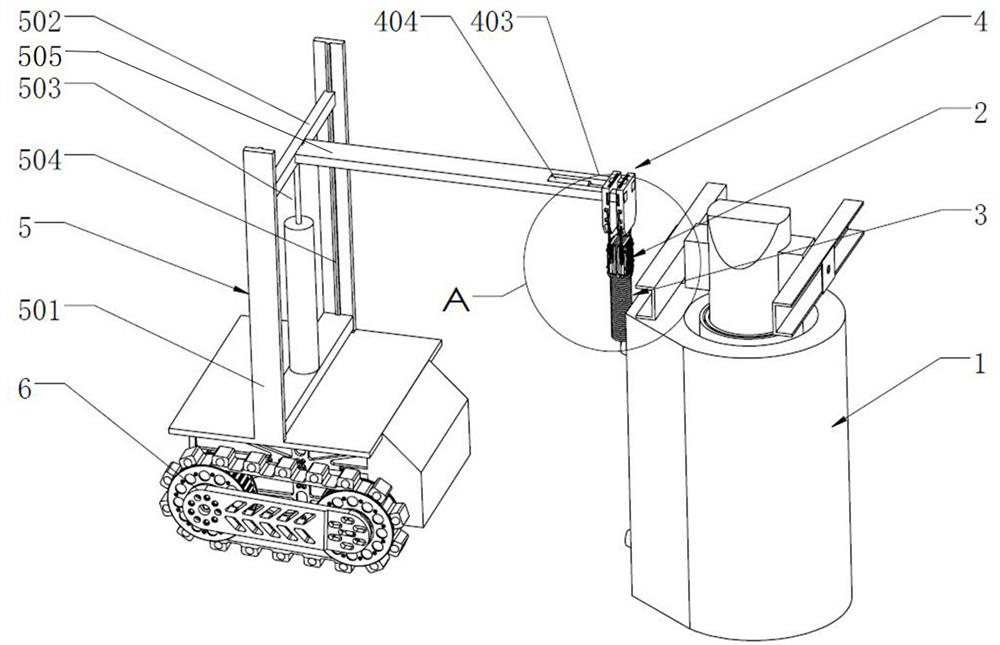

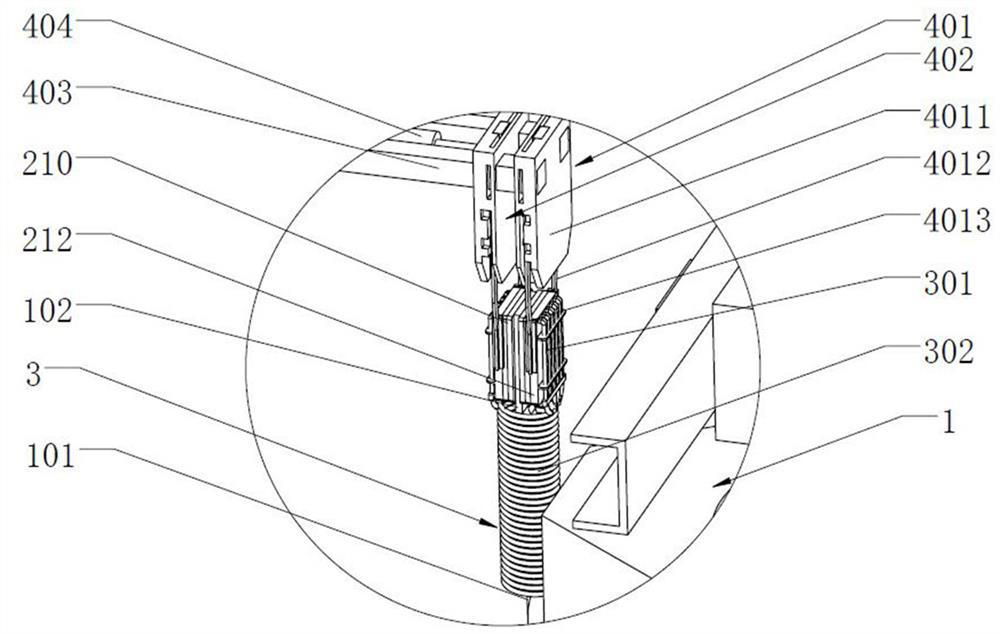

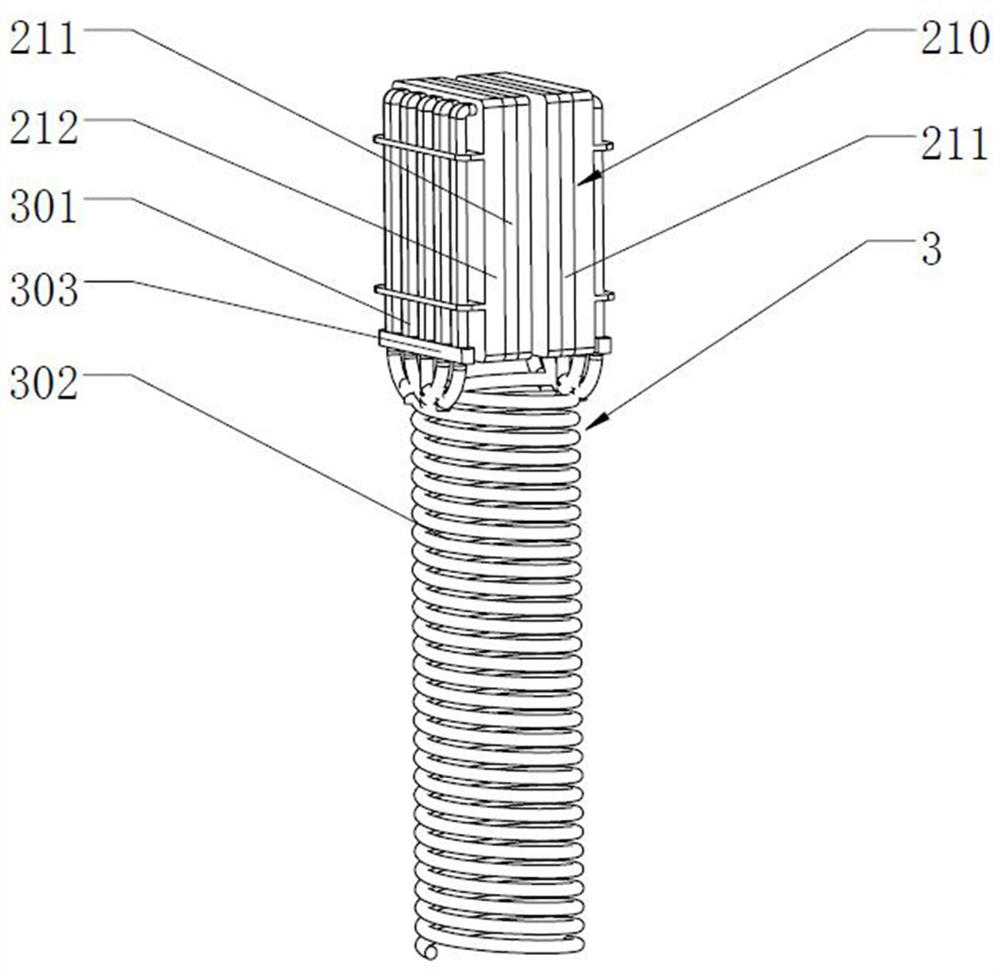

PTC (Positive Temperature Coefficient) rapid heating device and method for dry-type distribution transformer winding

A distribution transformer and rapid heating technology, which is applied in the direction of electric heating devices, ohmic resistance heating parts, electrical components, etc., can solve the problems of manual operation, low heating efficiency, and heat dissipation when installing and disassembling PTC heaters. Achieve the effect of realizing automatic control, improving heating efficiency and reducing energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be described in detail below. It should be noted that the embodiments described herein are only used for illustration and are not used to limit the present invention. In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be apparent, however, to one of ordinary skill in the art that these specific details need not be employed to practice the present invention. In other instances, well-known circuits, software, or methods have not been described in detail in order to avoid obscuring the present invention.

[0041]Throughout this specification, references to "one embodiment," "an embodiment," "an example," or "an example" mean that a particular feature, structure, or characteristic described in connection with the embodiment or example is included in the present invention in at least one embodiment. Thus, appearances of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com