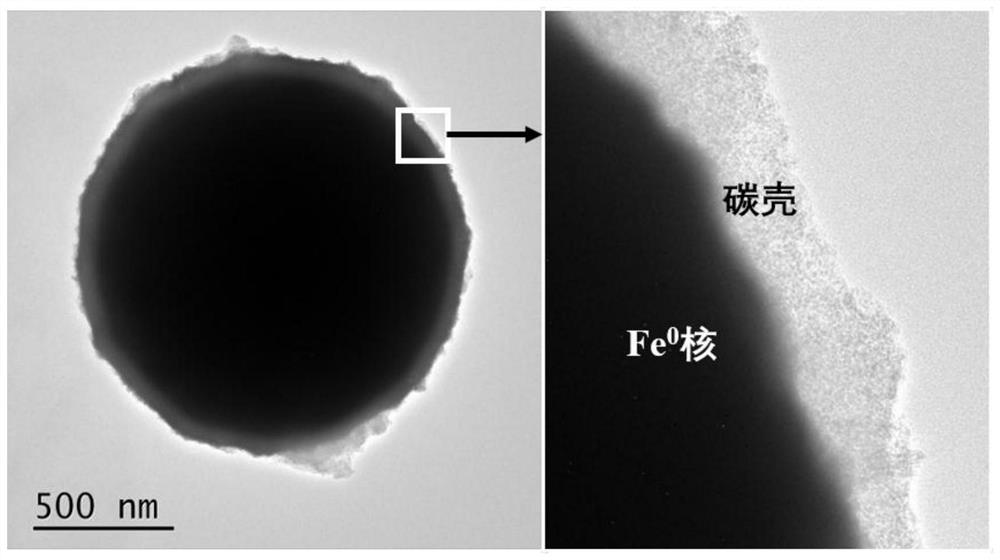

Preparation method and application of slow-release micro-nano zero-valent iron material

A micro-nano, zero-valent iron technology, applied in chemical instruments and methods, improvement of process efficiency, contaminated groundwater/leachate treatment, etc., can solve unfavorable carbon-coated iron material preparation, low conversion rate of humic acid, humic acid Low acid yield and other problems, achieve the effect of maintaining particle size and shape, low cost, and high conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

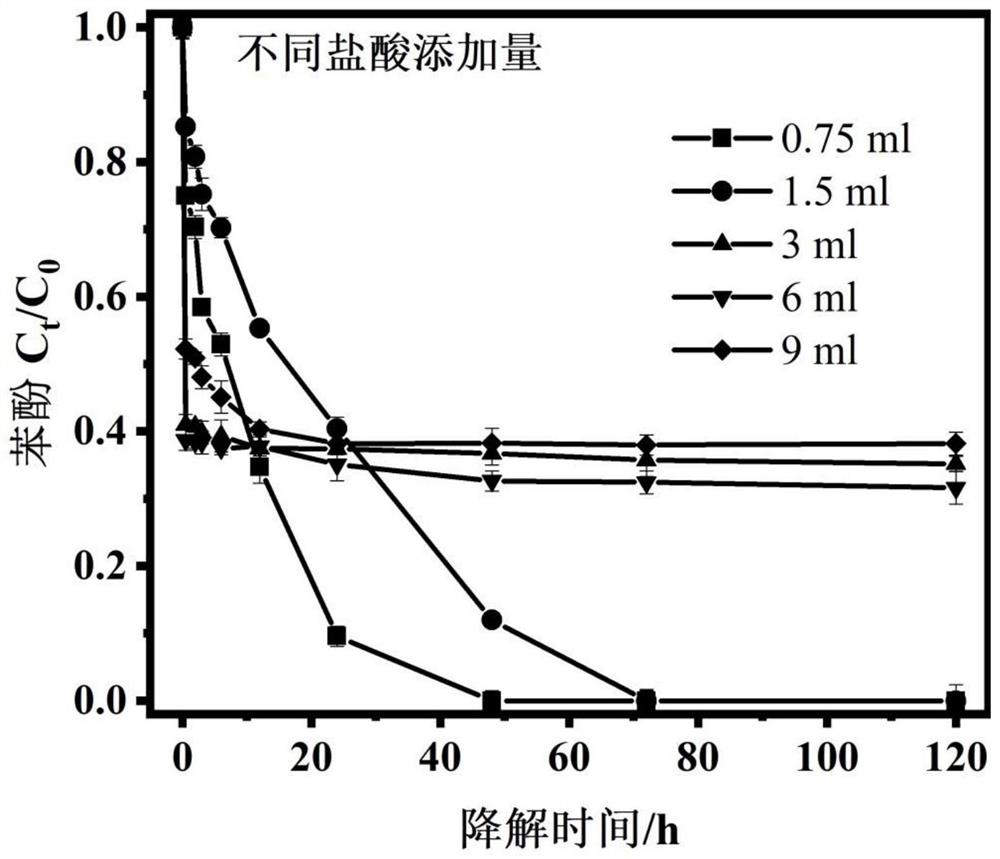

Examples

Embodiment 1

[0047] A preparation method of slow-release micro-nano zero-valent iron material, comprising the following steps:

[0048] S1 biomass high temperature pretreatment

[0049] Grind the rice straw biomass raw materials into powder, and in a pyrolysis furnace, under nitrogen protection, the temperature is raised to 300 °C at a rate of 5 °C / min and maintained for 1 h, and after natural cooling, the pretreated raw materials are obtained by grinding;

[0050] Preparation of Humic Acid by Hydrothermal Alkali Catalysis of S2 Pretreated Raw Material

[0051] Weigh 1 g of the pretreated raw material and mix it with 50 g of 1M NaOH solution, transfer it to a 100 ml reaction kettle, heat it with water at 200 ° C for 12 h, and after natural cooling, the reaction solution is centrifuged to remove the residue, and under stirring conditions, use 2 M The pH of the reaction solution was adjusted by the strong acid solution to be less than 2, and stirring was continued for 30 min. After the humi...

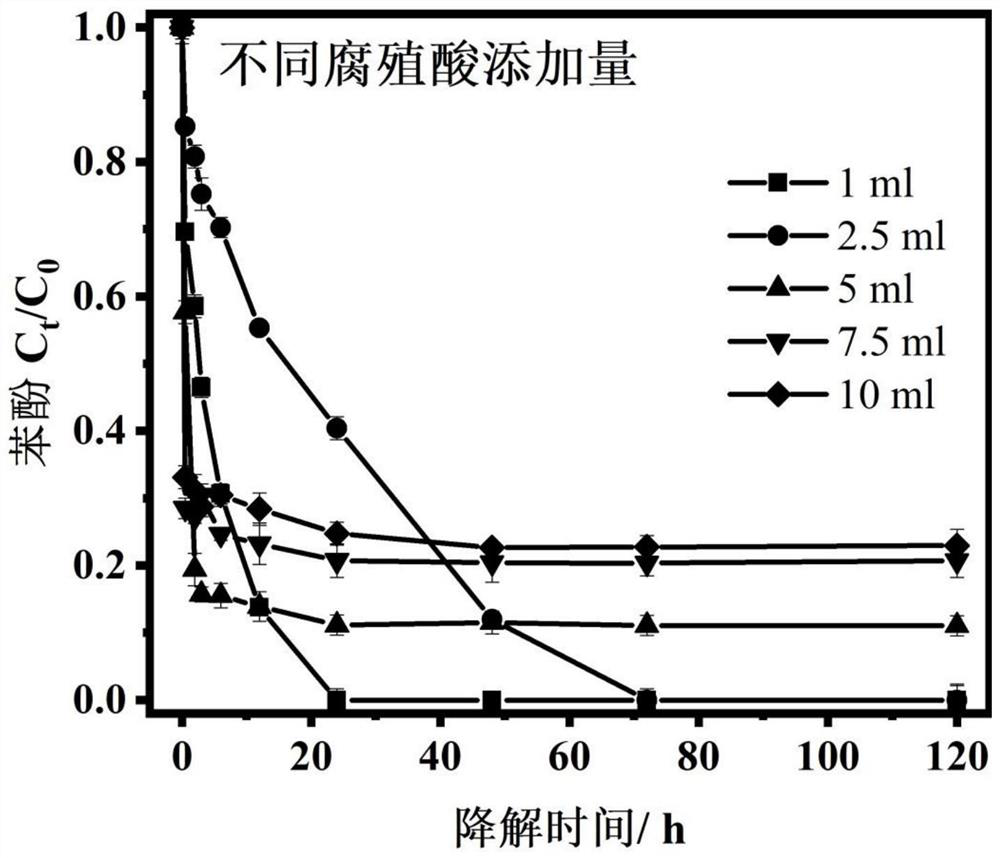

Embodiment 2

[0055] A preparation method of slow-release micro-nano zero-valent iron material, comprising the following steps:

[0056] S1 biomass high temperature pretreatment

[0057] Grind the rice straw biomass raw materials into powder, and in a pyrolysis furnace, under nitrogen protection, the temperature is raised to 300 °C at a rate of 5 °C / min and maintained for 1 h, and after natural cooling, the pretreated raw materials are obtained by grinding;

[0058] Preparation of Humic Acid by Hydrothermal Alkali Catalysis of S2 Pretreated Raw Material

[0059] Weigh 1 g of the pretreated raw material and mix it with 50 g of 1M NaOH solution, transfer it to a 100 ml reaction kettle, heat it with water at 200 ° C for 12 h, and after natural cooling, the reaction solution is centrifuged to remove the residue, and under stirring conditions, use 2 M The pH of the reaction solution was adjusted by the strong acid solution to be less than 2, and stirring was continued for 30 min. After the humi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com