Black metal polishing solution containing phosphorus borate and preparation method of black metal polishing solution

A ferrous metal and polishing liquid technology, applied in the field of polishing liquid, can solve the problems of poor biodegradability and large pollution of chlorinated paraffin, and achieve excellent anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a phosphorus-containing borate water-based lubricant, comprising the steps:

[0041] (1) 2.5% boric acid, 70% TX-9, 6.5% glycerol are put into the reactor, and react under the condition of vacuuming and constant stirring, temperature of reaction is 80 ℃, and the reaction times is 120 minutes;

[0042] (2) close the vacuum, the temperature in the reaction kettle is cooled to below 50 ℃, then slowly add 4% phosphorus pentoxide in the reaction kettle, continuously stir, control the reaction temperature to be below 90 ℃, and stir 60 minutes after the feeding is completed;

[0043] (3) control temperature below 90 ℃, add 17% pure water to the reactor, stir for 60 minutes;

[0044] (4) temperature of reaction kettle is lowered to room temperature, discharging;

[0045] The TX-9, boric acid, glycerol, phosphorus pentoxide and pure water are all industrial grades.

Embodiment 2

[0047] A preparation method of a phosphorous borate-containing ferrous metal polishing liquid, comprising the following steps:

[0048] (1) first mix triethanolamine and phosphorus-containing borate water-based lubricant (made in Example 1) to prepare an additive with slow-release properties;

[0049] (2) adding oleic acid triethanolamine, NP-10, organosilicon defoaming agent and the additive obtained in step (1) in sequence in water, stirring evenly, to obtain the ferrous metal polishing liquid.

[0050] The black metal polishing liquid is a tan transparent liquid with a pH of 9-10.

[0051] The raw materials contained in the ferrous metal polishing liquid and the mass percentage of each raw material are:

[0052]

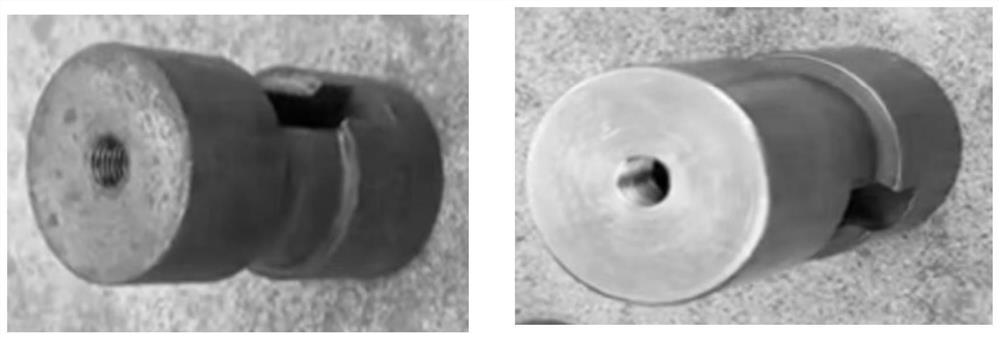

[0053] The polishing liquid prepared in this example is diluted with soft water to a concentration of 6% of the polishing liquid, matched with steel balls in the polishing equipment, and the stainless steel heating rods before and after treatment are as follow...

Embodiment 3

[0055] A preparation method of a phosphorous borate-containing ferrous metal polishing liquid, comprising the following steps:

[0056] (1) first mix triethanolamine and phosphorus-containing borate water-based lubricant (made in Example 1) to prepare an additive with slow-release properties;

[0057] (2) adding oleic acid triethanolamine, NP-10, organosilicon defoaming agent and the additive obtained in step (1) in sequence in water, stirring evenly, to obtain the ferrous metal polishing liquid.

[0058] The black metal polishing liquid is a tan transparent liquid with a pH of 9-10.

[0059] The raw materials contained in the ferrous metal polishing liquid and the mass percentage of each raw material are:

[0060]

[0061]

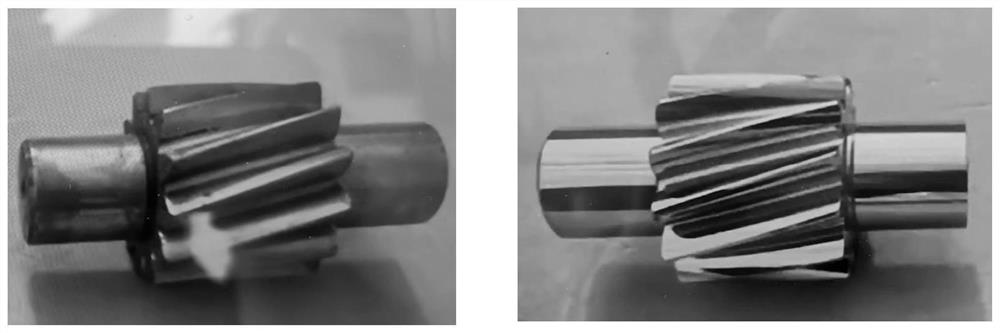

[0062] The polishing liquid prepared in this example is diluted with soft water to a concentration of 5% of the polishing liquid, matched with steel balls in the polishing equipment, and the gears before and after treatment are as follows: figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com