Method and device for centralized collection of carbon dioxide in electrolytic aluminum production

A carbon dioxide collection device technology, applied in the field of electrolytic aluminum, can solve problems such as loss of industrial recycling value, flue gas escape, and increased energy consumption of electrolytic aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

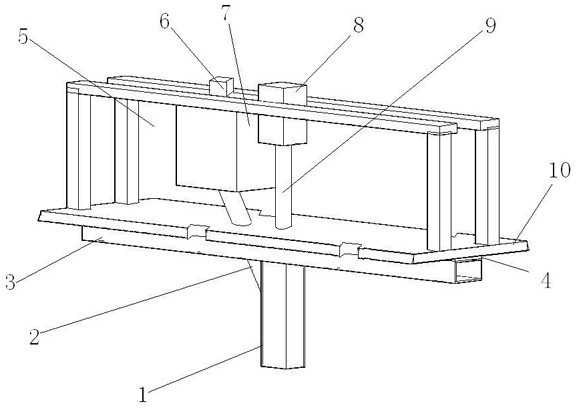

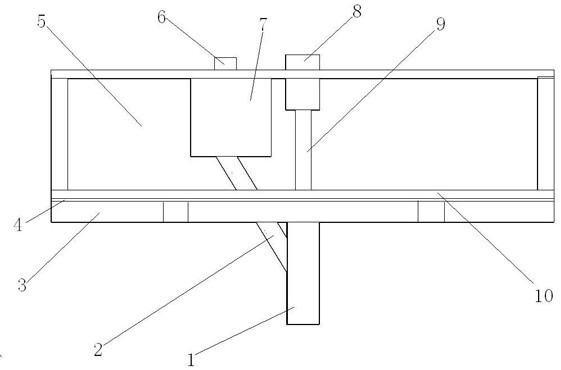

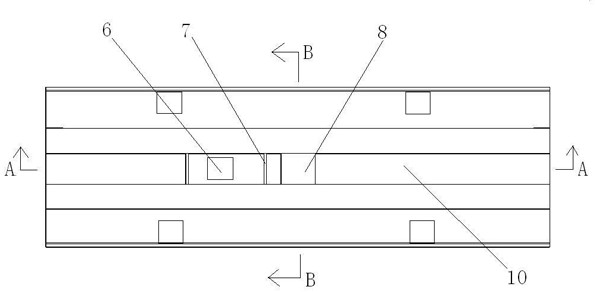

Image

Examples

Embodiment 1

[0028] A method for centrally collecting carbon dioxide in the production of electrolytic aluminum of the present invention is characterized in that it comprises the following steps;

[0029] 1) Preparation before electrolysis and buried flue gas pipe

[0030]A lining material 15 is laid on the inner bottom and sides of the tank shell 11. After the cathode carbon block 16 with the cathode steel rod 13 inserted into the inner bottom of the lining material 15 is placed, two rows of several anodes 14 are hung on the trolley. The guide rod is clamped into the cover plate 10, the bottom of the carbon block is suspended, and then the aluminum liquid 17 and the electrolyte liquid 18 are respectively placed, and the carbon block at the lower end of the anode 14 is immersed in the electrolyte liquid 18. A number of flue gas pipes 1 are installed, and a layer of furnace surface insulation material 19 is covered on the carbon block at the lower end of the anode 14. In the space, cover t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com