Epitaxial wafer preparation method for improving doping efficiency and epitaxial growth equipment

A technology of doping efficiency and epitaxial wafers, which is applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of affecting the radiation recombination efficiency of electrons and holes, uneven distribution, and low activation efficiency, so as to improve uniformity Distributed, evenly distributed, facilitated flow and reaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present disclosure clearer, the embodiments of the present disclosure will be further described in detail below with reference to the accompanying drawings.

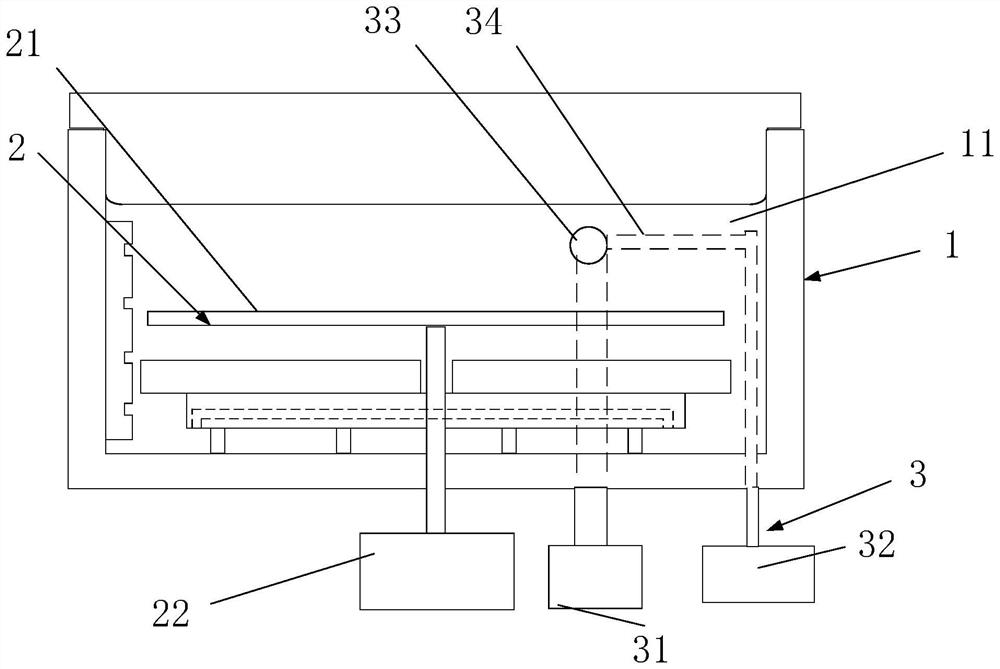

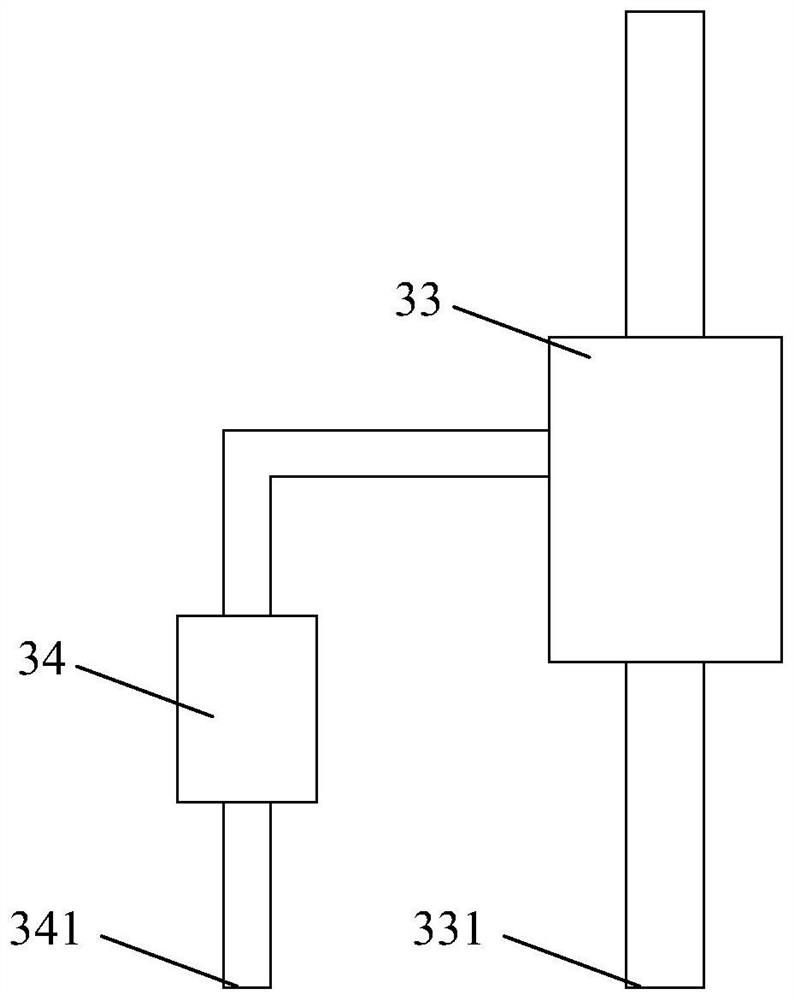

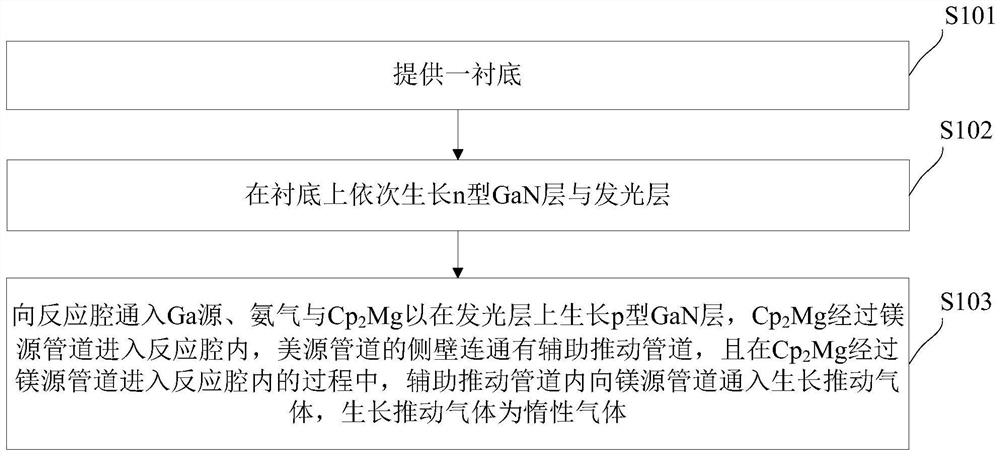

[0030] For ease of understanding, the basic structure of the epitaxial growth equipment for preparing epitaxial wafers will be described first. figure 1 is a simplified schematic structural diagram of the epitaxial growth equipment provided by the embodiment of the present disclosure, refer to figure 1 It can be known that an embodiment of the present disclosure provides an epitaxial growth apparatus, and the epitaxial growth apparatus includes a mounting base 1 , a substrate placing part 2 and a gas conveying part 3 . The mounting base 1 includes a reaction chamber 11 , the substrate placement part 2 is located in the reaction chamber 11 and is used to place the substrate, and the gas conveying part 3 includes a magnesium source conveying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com