Resistance spot welding butt joint process

A technology of resistance spot welding and process, applied in the direction of resistance welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as joint quality decline, nugget offset, nugget size small, etc., to solve the nugget Effects of small size, increased nugget size, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

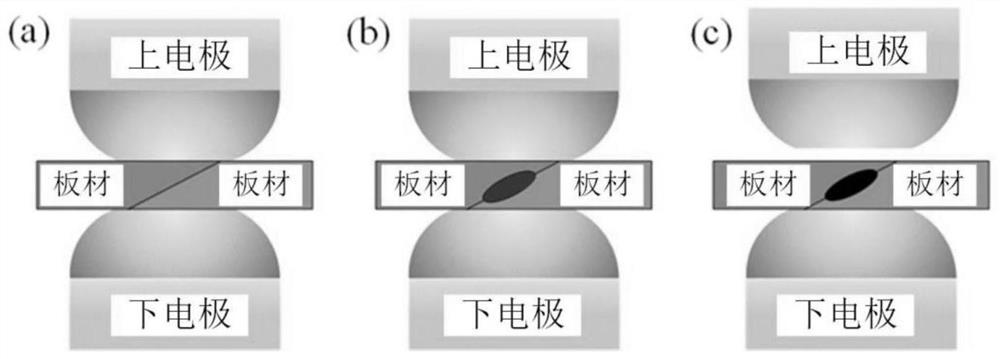

[0049] refer to figure 1 , a resistance spot welding butt welding process, comprising the following steps:

[0050] (1) Contact the upper electrode with the first workpiece to be welded;

[0051] (2) contacting the lower electrode with the second workpiece to be welded;

[0052] (3) Abutting the first workpiece to be welded and the second workpiece to be welded, the first butt surface of the first workpiece to be welded and the second butt surface of the second workpiece to be welded are in direct contact (see figure 1 in (a));

[0053] (4) Apply pressure and welding current to the upper electrode and the lower electrode to perform resistance spot welding, and the size of the nugget gradually changes during the spot welding process, see figure 1 in (b) and (c).

[0054] Wherein, the first workpiece to be welded and the second workpiece to be welded are both 4mm 5754 aluminum alloy; the upper electrode and the lower electrode are electrodes made of CuCrZr material.

[0...

Embodiment 2

[0058] A resistance spot welding butt welding process, comprising the following steps:

[0059] (1) Contact the upper electrode with the first workpiece to be welded;

[0060] (2) contacting the lower electrode with the second workpiece to be welded;

[0061] (3) butting the first workpiece to be welded and the second workpiece to be welded, the first butt surface of the first workpiece to be welded and the second butt surface of the second workpiece to be welded are in direct contact;

[0062] (4) Resistance spot welding is performed by applying pressure and welding current to the upper electrode and the lower electrode.

[0063] Wherein, the first workpiece to be welded and the second workpiece to be welded are both 4mm 5754 aluminum alloy; the upper electrode and the lower electrode are electrodes made of CuCrZr material.

[0064] Wherein, the first abutting surface and the second abutting surface are inclined surfaces that cooperate with each other, and the slope angle o...

Embodiment 3

[0067] A resistance spot welding butt welding process, comprising the following steps:

[0068] (1) Contact the upper electrode with the first workpiece to be welded;

[0069] (2) contacting the lower electrode with the second workpiece to be welded;

[0070] (3) butting the first workpiece to be welded and the second workpiece to be welded, the first butt surface of the first workpiece to be welded and the second butt surface of the second workpiece to be welded are in direct contact;

[0071] (4) Resistance spot welding is performed by applying pressure and welding current to the upper electrode and the lower electrode.

[0072] Wherein, the first workpiece to be welded and the second workpiece to be welded are both 4mm 5754 aluminum alloy; the upper electrode and the lower electrode are electrodes made of CuCrZr material.

[0073] Wherein, the first abutting surface and the second abutting surface are inclined surfaces that cooperate with each other, and the slope angle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com