Soundproof cotton board film covering and tapping machine capable of preventing flying chips

A technology of sound-proof cotton and opening machine, which is applied in the direction of cleaning methods and utensils, chemical instruments and methods, and removal of smoke and dust, and can solve problems such as polluting the environment, hearing loss, and falling out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

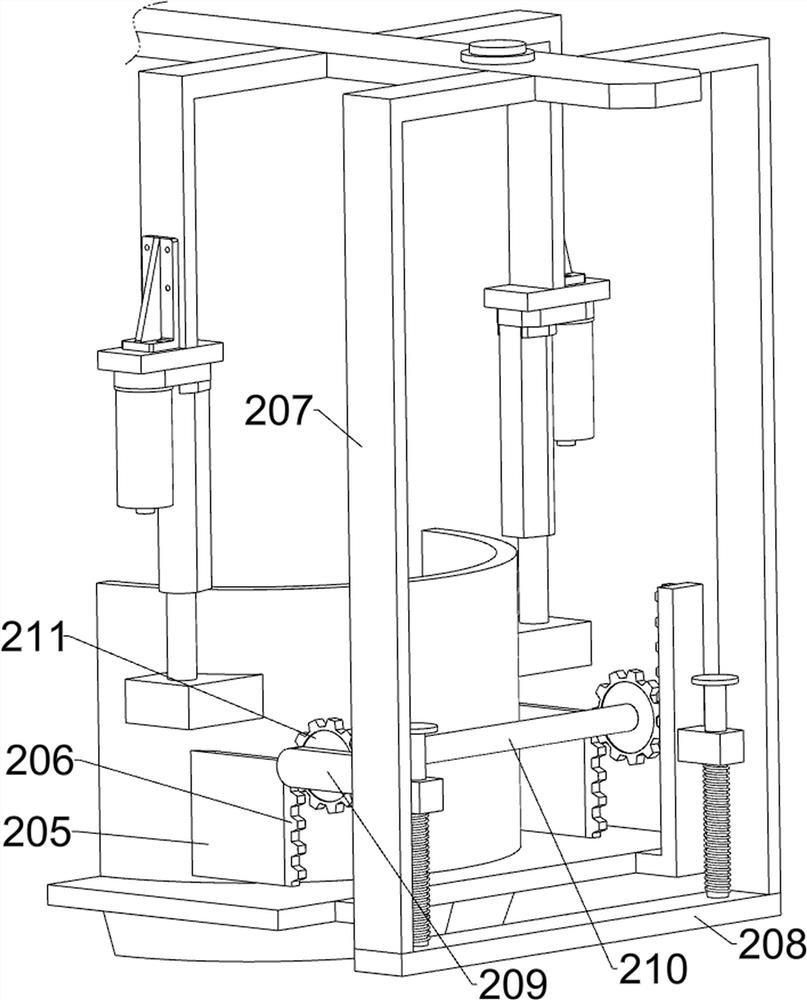

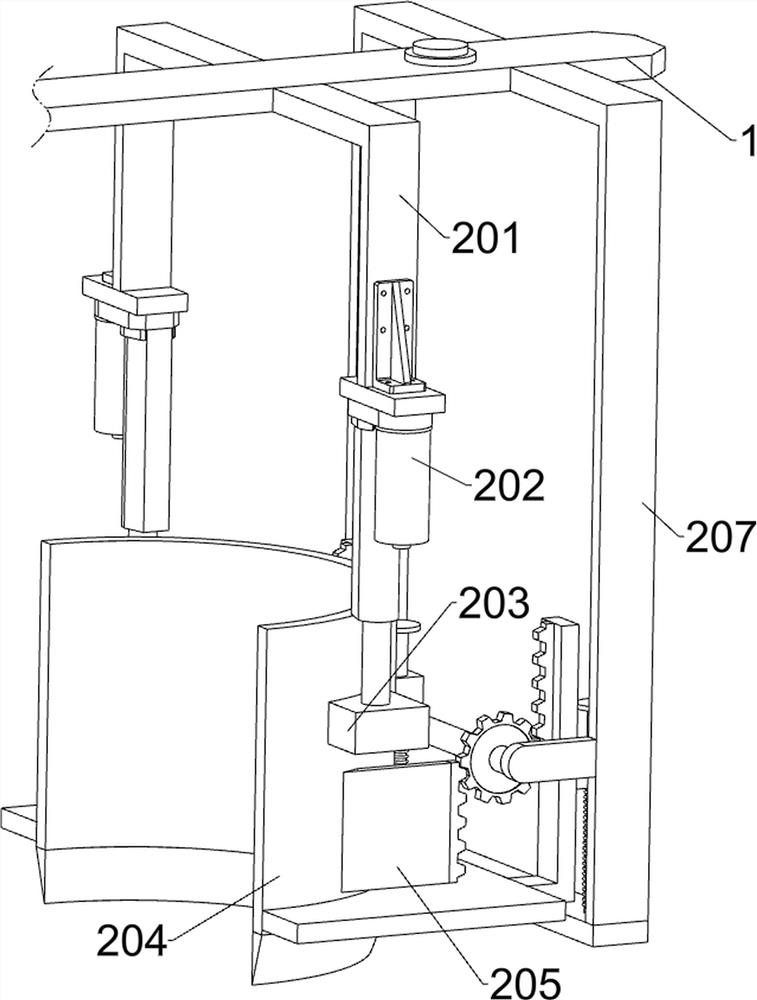

[0029] A kind of anti-scraping sound insulation cotton board laminating machine, such as Figure 1-7 As shown, it includes a support plate 1, an opening system and an insertion system; the right part of the support plate 1 is connected with the opening system; the middle part of the support plate 1 is connected with an insertion system.

[0030]The opening system includes a first L-shaped plate 201, a first electric push rod 202, a first connecting block 203, a cutting plate 204, a first connecting plate 205, a first gear tooth plate 206, a second L-shaped plate 207, A fixed plate 208 , a second engaging block 209 , a rotating shaft rod 210 , a first spur gear 211 , a sliding rod 212 , a connecting slider 213 , a spring 214 , a third L-shaped plate 215 , a second gear tooth plate 216 , and a pressing plate 217 and the air nozzle 218; a first L-shaped plate 201 is fixedly connected to each of the front right part and the rear right part of the support plate 1; Each of the tele...

Embodiment 2

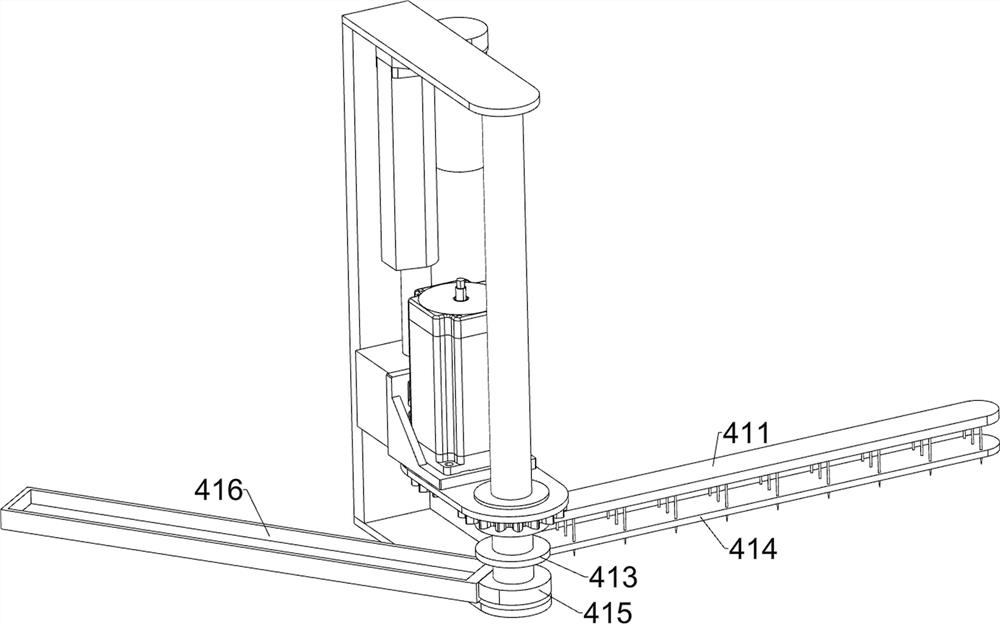

[0040] On the basis of Example 1, as figure 1 and Figure 8-10 As shown, it also includes a cleaning system; the left part of the lower side of the support plate 1 is connected with a cleaning system; the cleaning system includes a connecting plate 401, a U-shaped plate 402, a fixing column 403, a fourth electric push rod 404, and a fifth connecting block 405 , motor 406, fourth connecting plate 407, second spur gear 408, rotating cylinder 409, third spur gear 410, second fixing plate 411, chip cleaning thorn 412, first connecting column 413, chip scraping plate 414, second The connecting column 415 and the collecting box 416; the connecting plate 401 is fixedly connected to the lower left part of the support plate 1; the U-shaped plate 402 is fixedly connected to the lower side of the connecting plate 401; A fixed column 403 is fixedly connected between them; a fourth electric push rod 404 is bolted to the upper left part of the U-shaped plate 402; the telescopic end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com