Jet composite electro-deposition device

A composite electrodeposition and spray device technology, applied in electroforming, electrolysis components, electrolysis process, etc., can solve problems such as staying in the laboratory stage, and achieve the effect of improving shape diversity, improving deposition efficiency, and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

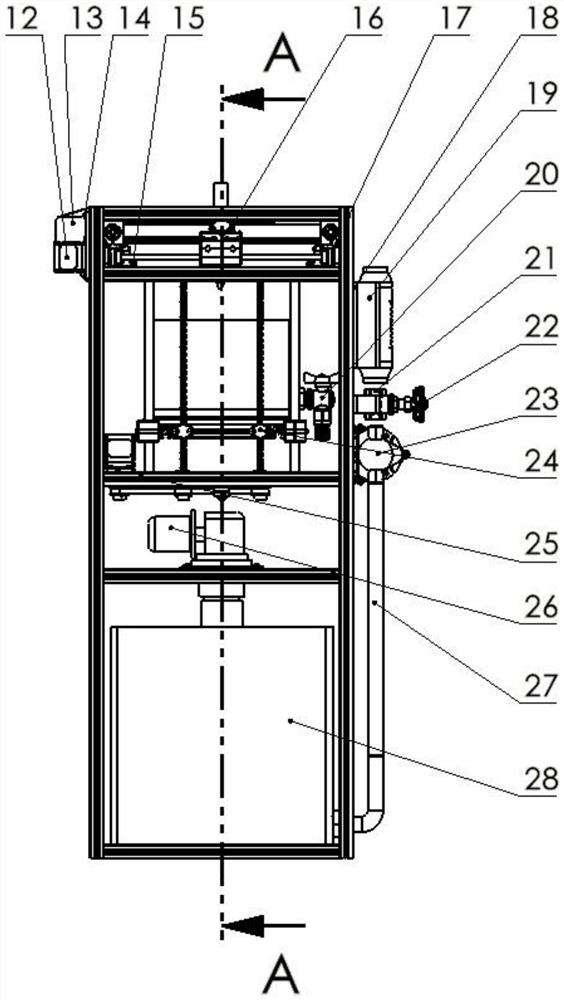

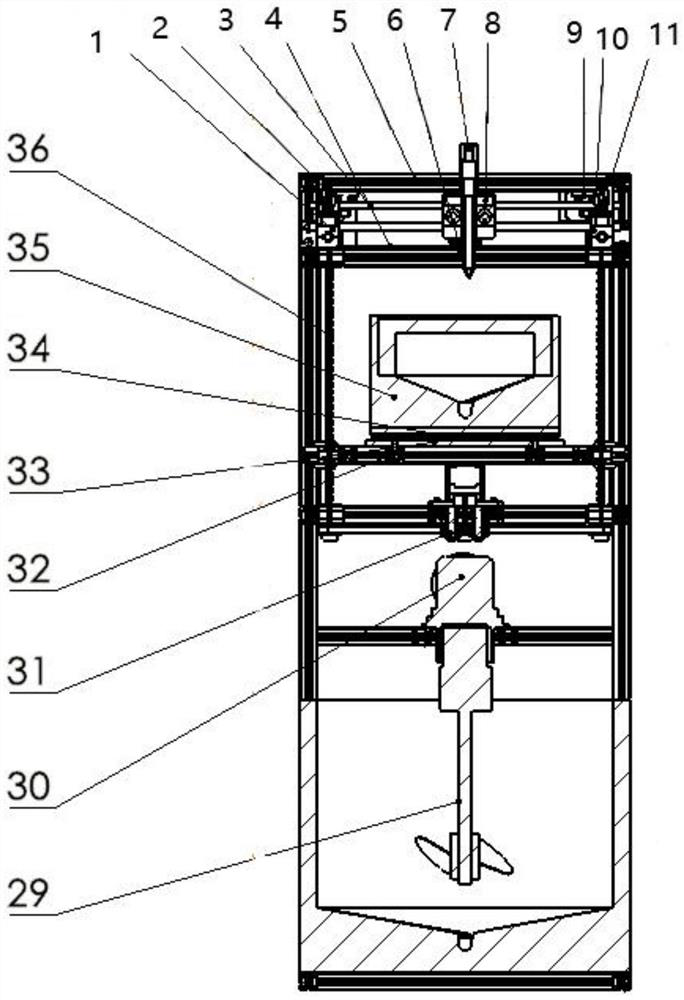

[0029] Example: see Figure 1-4 , the present invention provides a technical solution: a spray composite electrodeposition device, including a numerical control machining device, a high-efficiency spray device and an electrolyte circulation device,

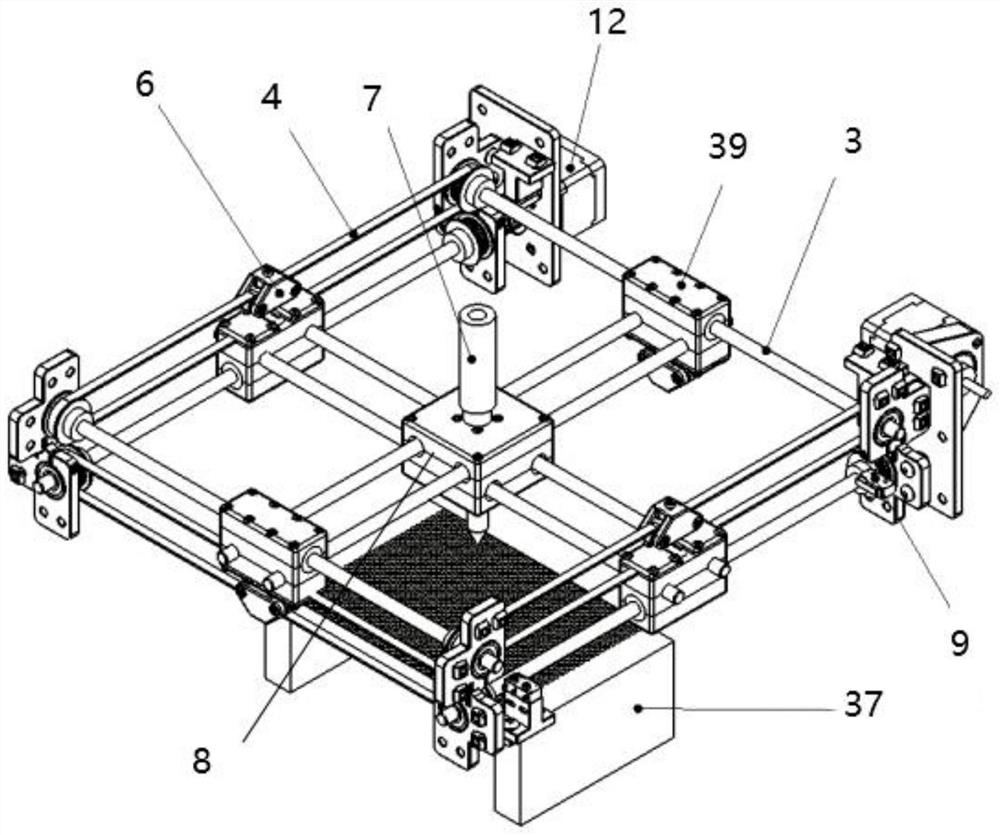

[0030] The numerical control processing device consists of bearing 1, synchronous wheel 2, polished rod 3, synchronous belt 4, first aluminum profile 5, synchronous belt fixing block 6, electrolyte spray head 7, spray head fixing block 8, travel switch 9, stepper motor 12 and X , Y-axis motor fixing frame 13 is formed;

[0031] The electrolyte nozzle 7 is installed in the middle of the nozzle fixing block 8, and the bottom of the nozzle fixing block 8 is interspersed with movable rods in a crisscross pattern. , both ends of the polished rod 3 are fixedly connected with the synchronous wheel 2, the synchronous wheel 2 is provided with a synchronous belt 4, the synchronous belt 4 is installed with a synchronous belt fixing block 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com