Novel wet digestion method

A new type of wet digestion technology, applied in the preparation of test samples, plastic recycling, recycling technology, etc., can solve the problems of expensive instruments, dangerous high temperature and high pressure environment of microwave digestion instruments, inability to digest with sulfuric acid, etc., to reduce high temperature Risk of high pressure, improving digestion efficiency, preventing ion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

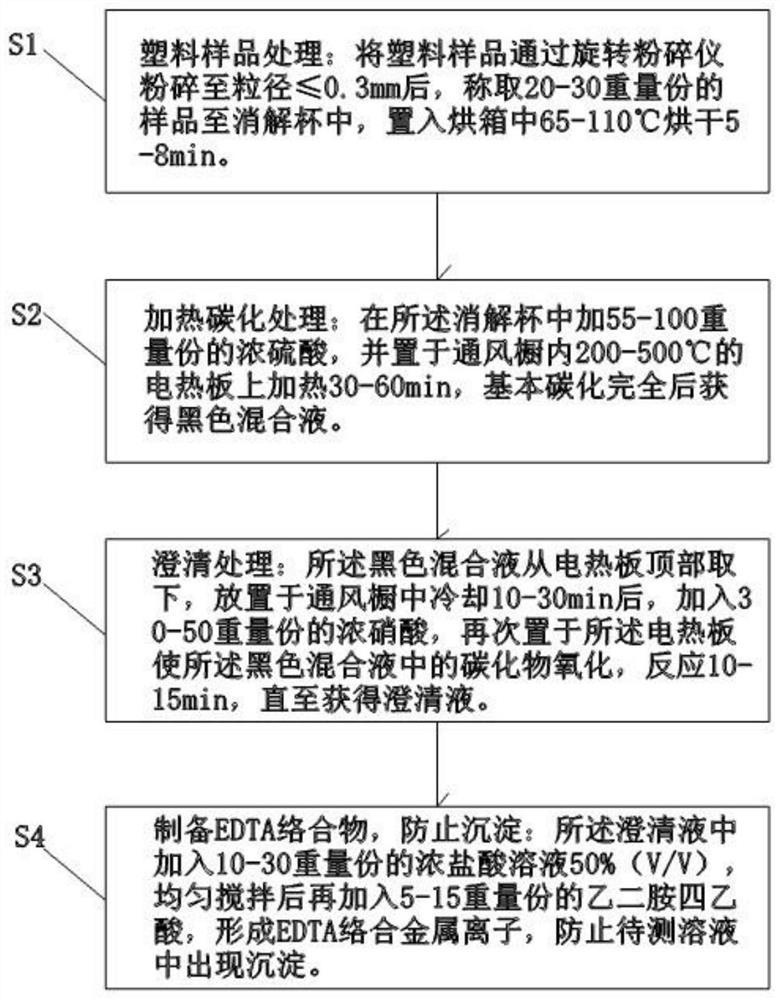

[0024] see figure 1 , the present invention provides a technical scheme: a novel wet digestion method, comprising the following steps:

[0025] Step 1. Plastic sample processing: After the plastic sample is crushed by a rotary pulverizer to a particle size of ≤0.3mm, 20-30 parts by weight of the sample are weighed into the digestion cup. The value during the weighing of the plastic sample is accurate to 0.001g. Put it in an oven to dry at 110 °C for 8 min.

[0026] Step 2. Heating and carbonizing treatment: add 100 parts by weight of concentrated sulfuric acid to the digestion cup, the mass fraction of concentrated sulfuric acid is 1.80-1.84 g / ml, and place it on an electric hot plate at 500°C in a fume hood to heat for 60 minutes, and the carbonization is basically complete. Then a black mixture was obtained. When the concentrated sulfuric acid is added to the digestion cup for carbonization, observe whether white gas escapes during the heating and reflux reaction; if the w...

Embodiment 2

[0030] The novel wet digestion method provided in this example is roughly the same as that in Example 1, and its main difference is:

[0031] In step 2, add 55 parts by weight of concentrated sulfuric acid to the digestion cup, the mass fraction of concentrated sulfuric acid is 1.80-1.84g / ml, and place it on an electric hot plate at 200°C in a fume hood to heat for 30min, and obtain a black color after the basic carbonization is complete. mixture.

Embodiment 3

[0033] The novel wet digestion method provided in this example is roughly the same as that in Example 1, and its main difference is:

[0034] In step 3, the black mixed solution is removed from the top of the electric hot plate, placed in a fume hood to cool for 60 minutes, then 20 parts by weight of concentrated nitric acid is added, the mass fraction of concentrated nitric acid is 1.40-1.44g / ml, and it is placed on the electric hot plate again The carbides in the black mixture were oxidized and reacted for 3 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com