Lead bonding on-line monitoring method based on digital twinning technology

A wire bonding and twinning technology, applied in neural learning methods, electrical digital data processing, biological neural network models, etc., can solve the problem of few online detection parameters, difficulty in describing various constitutive relations, and inability to realize macroscopic real-time simulation and other issues to achieve real-time simulation, improve robustness, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make it easy to understand the technical means, creation features, work flow, use method, purpose and effect of the present invention, the present invention is further described below with reference to the accompanying drawings.

[0032] see figure 1 . In the existing bonding machine, the rivet 3 is usually driven by the driving device on the worktable to weld the metal leads to the pads 4. During this process, the gold wires and the pads can also be carried out by the transducer 5. heating. The purpose of the on-line monitoring method for wire bonding of the present invention is the on-line monitoring of the bonding process.

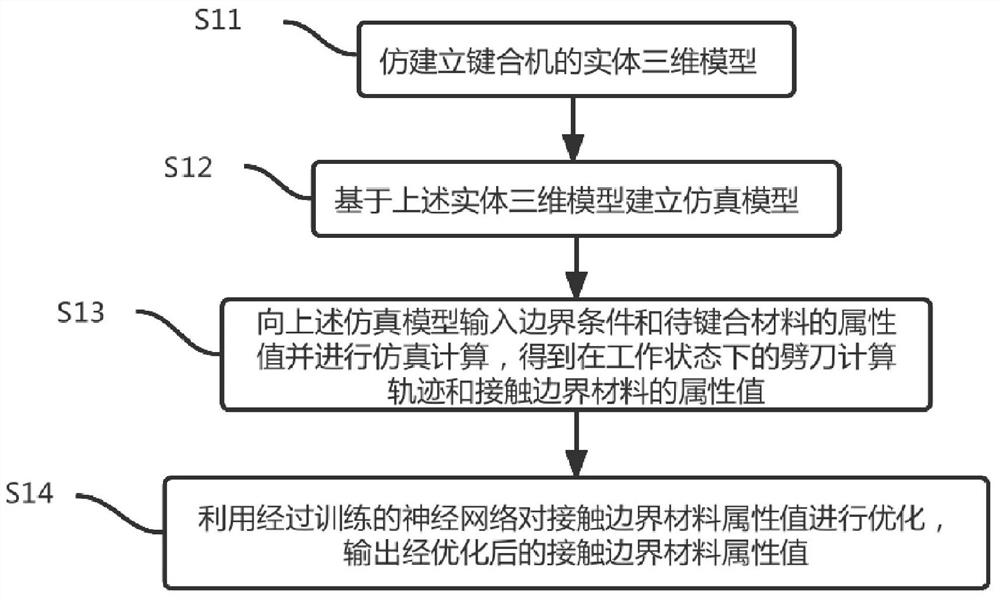

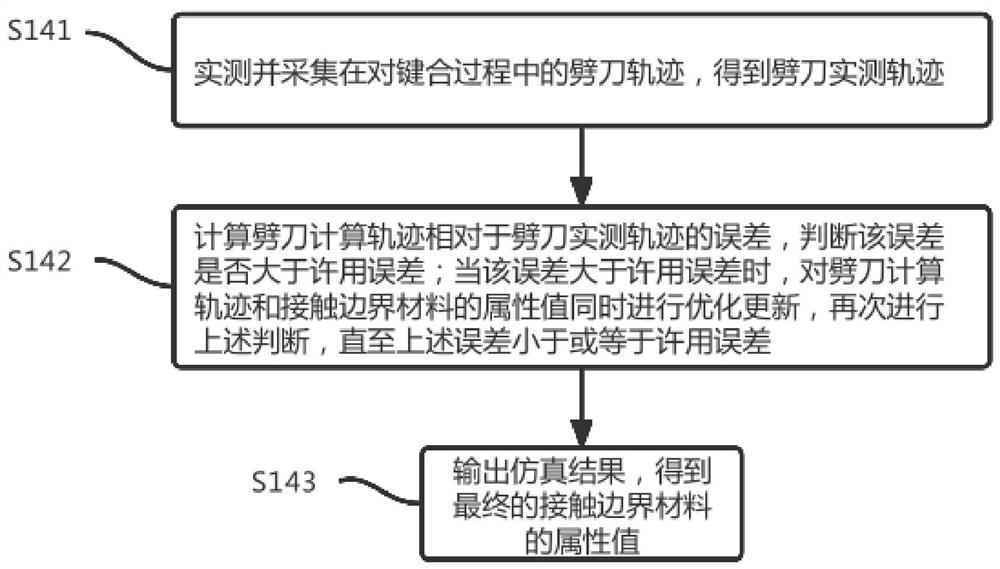

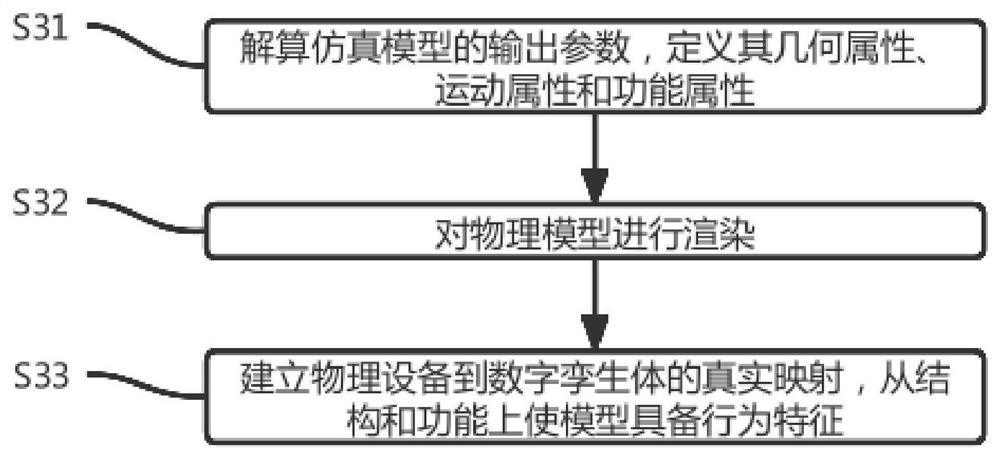

[0033] Please refer to figure 1 , Figure 8 and Figure 9 . In a preferred embodiment, the wire bonding online monitoring method of the present invention includes the following steps: S1, establishing a wire bonding simulation model and optimizing it; S2, establishing a wire bonding data model; S3, establishing a wire bonding V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com