Formation method of semiconductor structure

A technology of semiconductor and graphic structure, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc. It can solve the problems that the performance of semiconductor structures needs to be further improved, so as to improve the accuracy of graphic transmission, improve performance, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It can be known from the background art that the performance of the semiconductor structure formed by the current method for forming the zeroth metal layer cut-off structure (MOC) still needs to be improved. The reasons will now be described with reference to specific embodiments.

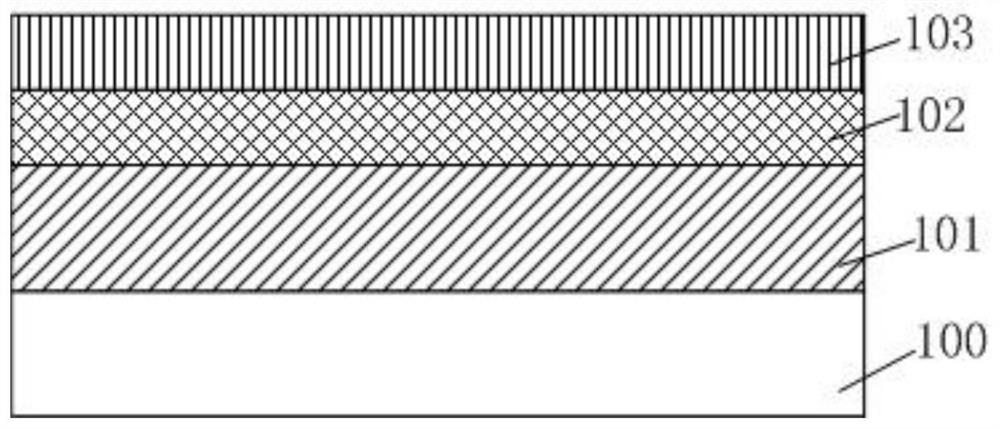

[0028] refer to figure 1 , a substrate 100 is provided, a dielectric layer 101 is formed on the substrate 100 ; a transition layer 102 and a sacrificial layer 103 located on the transition layer 102 are formed on the dielectric layer 101 .

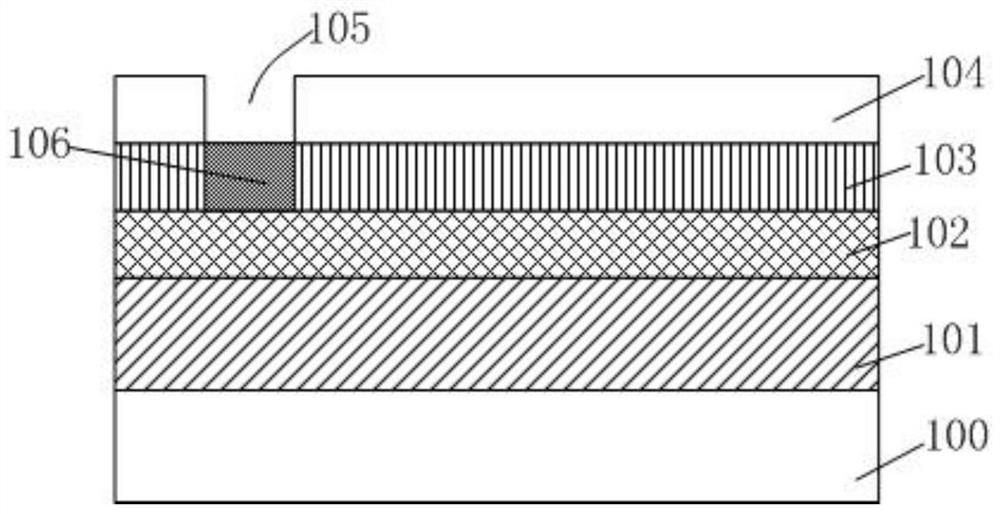

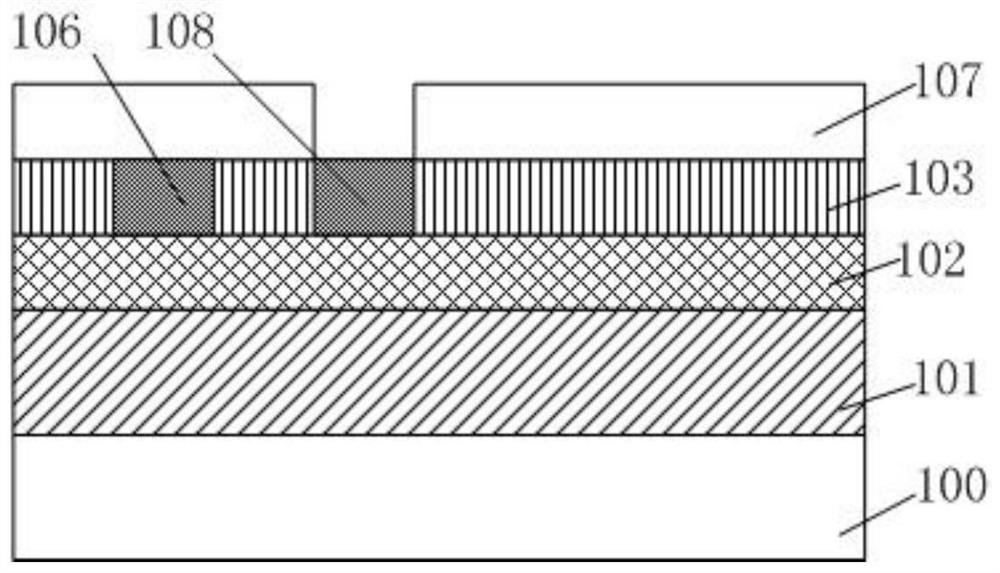

[0029] After the sacrificial layer 103 is formed, ion implantation is performed on the sacrificial layer 103 for multiple times to form a plurality of mutually separated modified layers in the sacrificial layer 103 respectively.

[0030] refer to figure 2 In this embodiment, the formation of four modified layers is taken as an example for description. The step of forming a single modified layer includes: forming a first patterned layer 104 on the sac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com