Radio frequency front-end assembly adopting high-performance ceramic material

A technology of radio frequency front-end and radio frequency components, which is applied in the field of communication, can solve problems such as poor performance, low efficiency, and high production cost, and achieve the effects of simple structure, saving transmission power, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

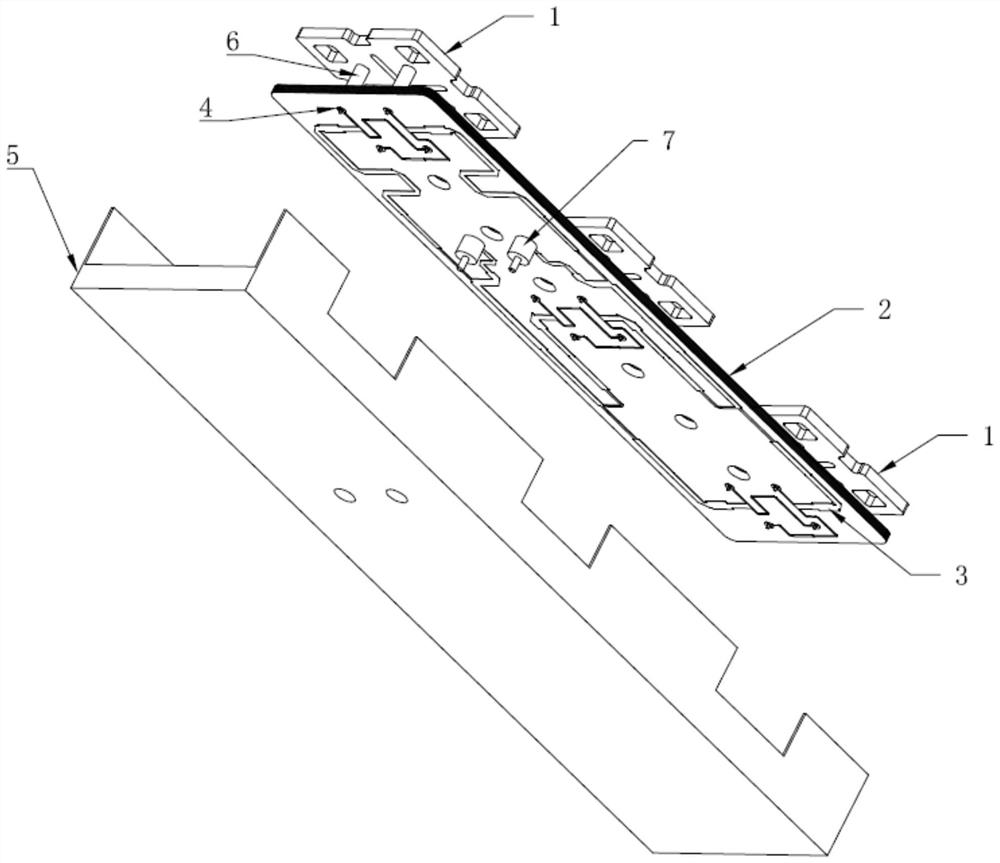

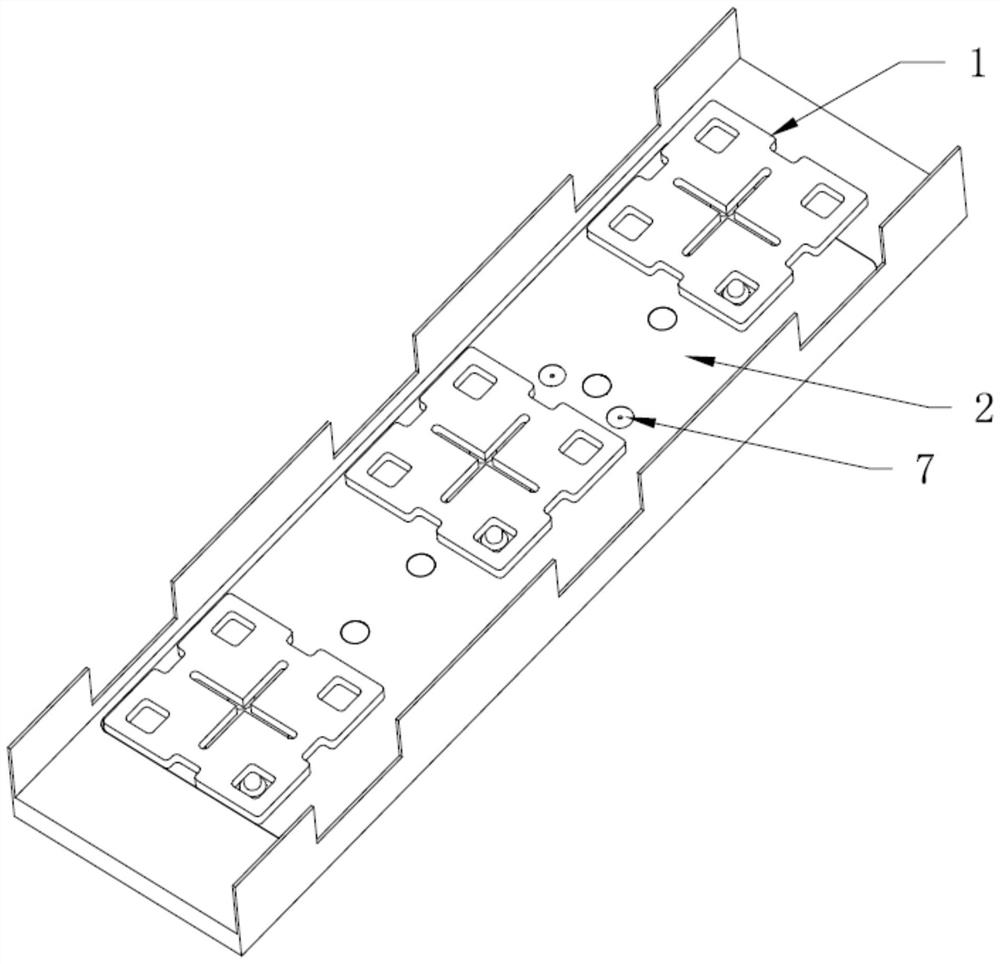

[0042] figure 1 and figure 2 It is a radio frequency front-end assembly composed of a single unit, including three metal radiating units 1, a core power division network substrate 2 and a mounting frame 5; the core power division network substrate 2 is fired from microwave dielectric ceramic materials. A dielectric ceramic substrate with a power division network and a shielding cover, a through hole 4 is provided on the core power division network substrate 2 for installing the pins 6 and signal terminals 7 of the metal radiating unit 1, and on the front side of the core power division network substrate 2 A non-metallic ring layer is provided around the through holes used to install the pins 6 and the signal terminals 7, and the width of the non-metallic ring layer is 1-10 mm; on the front side of the core power division network substrate 2, unless the metal ring layer is peripheral There is a metal layer; the four sides of the core power division network substrate 2 are met...

Embodiment 2

[0051] A protective cover made of an organic polymer is placed on a single RF front-end component in Example 1 to meet the needs of an all-weather working environment in a natural environment.

Embodiment 3

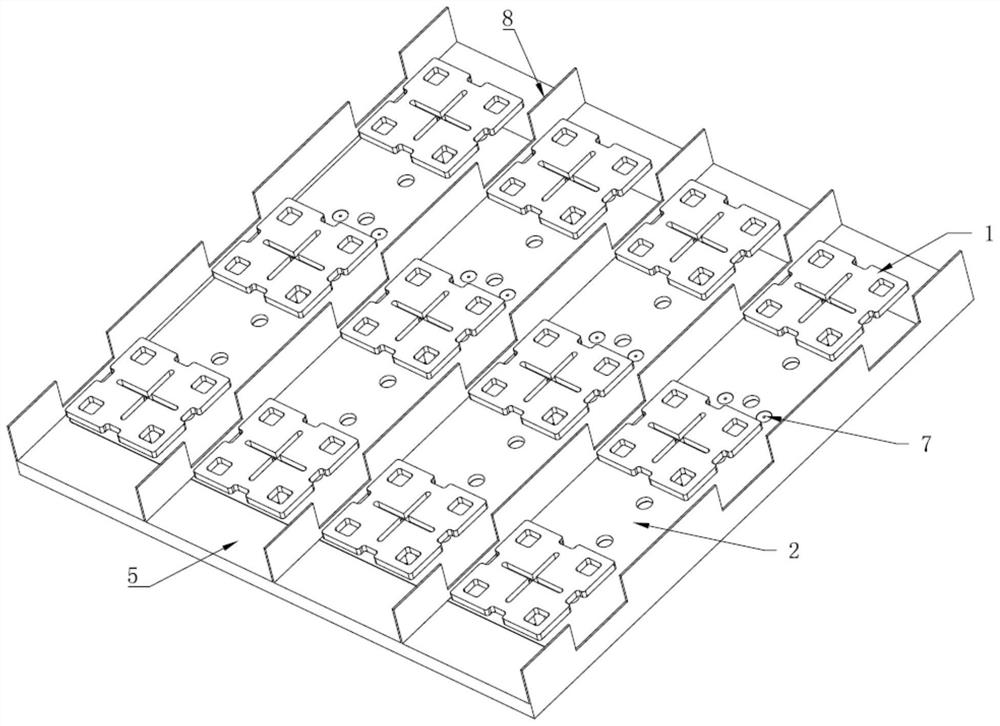

[0053] like image 3 As shown, on the basis of Embodiment 1, the number of the mounting frame 5 and the core power division network substrate 2 in the radio frequency front-end assembly is adjusted to obtain a radio frequency front-end assembly composed of four units.

[0054] The RF front-end assembly in this embodiment is composed of four installation frames 5, and spacers 8 are arranged between adjacent installation frames 5; a core power division network substrate 2 is installed in each installation frame 5, and each core power division network The substrate 2 is mounted with 3 pieces of metal radiation units 1 and 2 pieces of PIN pins as signal lead-out terminals 7 to form a four-unit mode.

[0055] The total size of the RF front-end component in this embodiment is 175mm×150mm×24mm, which is a high-performance RF front-end component that can be implemented within 3.3-3.75GHz, SWR22dB, and gain: 11.0-13.5dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com