Intelligent electric cabinet dehumidification device

An electric cabinet and intelligent technology, applied in substation/distribution device shell, separation method, separation of dispersed particles, etc., can solve problems such as secondary terminal breakdown, corrosion of steel structural parts, and mildew of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

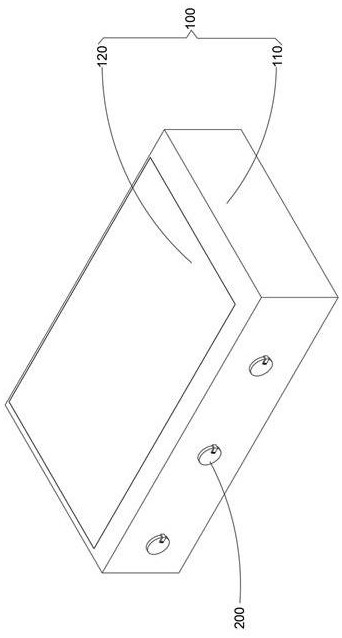

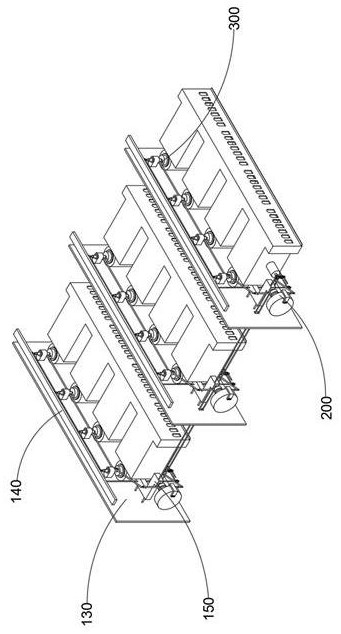

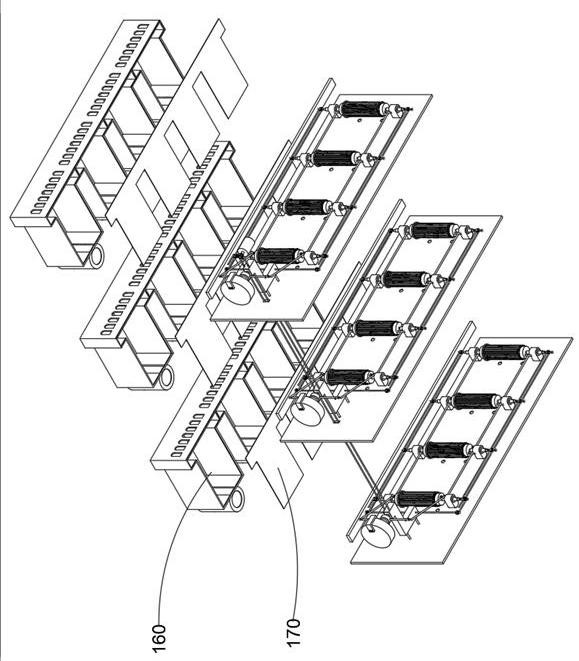

[0047] combine Figure 1-9 As shown, the intelligent electrical cabinet dehumidification device provided by the present invention includes a sealing mechanism 100, an airflow replacement mechanism 200, an airflow transmission mechanism 300, and an air bleed pipeline 400. The airflow replacement mechanism 200 is installed in the sealing mechanism 100, and the airflow transmission mechanism 300 is connected Inside the sealing mechanism 100 , and drivingly connected to the airflow displacement mechanism 200 , in addition, the air bleed pipeline 400 is connected to the airflow displacement mechanism 200 and the airflow transmission mechanism 300 .

[0048] The sealing mechanism 100 includes a hood 110, a sealing cover 120, a baffle 130, a backing plate 140, an auxiliary clamping slot 150, an electric meter cover 160 and a plug-in plate 170, and the airflow displacement mechanism 200 includes a motor 210, an air chamber shaft 220, a shaft 230, The transmission rod 240 , the ring bu...

Embodiment 2

[0051] combine Figure 5 and 6 As shown, on the basis of the first embodiment, the inwardly recessed chute is provided on the inner side of the two trapezoidal housings, so as to facilitate the safe rotation of the air chamber shaft 220 as a whole, and combined with its outer middle air pipe to penetrate to the moisture absorbing member The inner cavity of 290 extends to the inner third of the cavity, so that the dried air flow can be stably conveyed, and at the same time, combined with the absorption of heat energy by the turning element 270 itself, when the turning element 270 absorbs the anhydrous carbonic acid During the stirring of calcium, the external heat energy of the turning element 270 can heat and evaporate the anhydrous calcium carbonate powder, and use a larger cavity to store the turning element 270 and the anhydrous calcium carbonate powder, so that the processing can be improved. The rear air is discharged in an orderly manner. The cabin body 222 is composed ...

Embodiment 3

[0053] combine figure 1 , 2 , 3, 7 and 8, in the above embodiment, the turbine rods 330 symmetrically distributed in the vertical direction are arranged along the top and bottom holes of the mesh cylinder 361, and the transmission rod 240 is opposite to the two Under the driving action of the vertical shaft 310 , the two turbine rods 330 will form a directional airflow inside the mesh cylinder 361 , and combined with the meter ventilation element 360 as a whole, the secondary filter layer is realized by splicing, so that the airflow in the inner cavity of the meter cover 160 can be achieved. The moisture carried in the air is adsorbed, the turbine rod 330 is composed of a vertical rod, a fan blade and a gear, and the fan blade is adapted to be installed in the cylindrical air hood opened on the load-bearing member 340, and the mesh cylinder 361 is made of stainless steel. The mesh cylinder 361 is provided with evenly distributed fan-shaped slot holes, and two sides of the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com