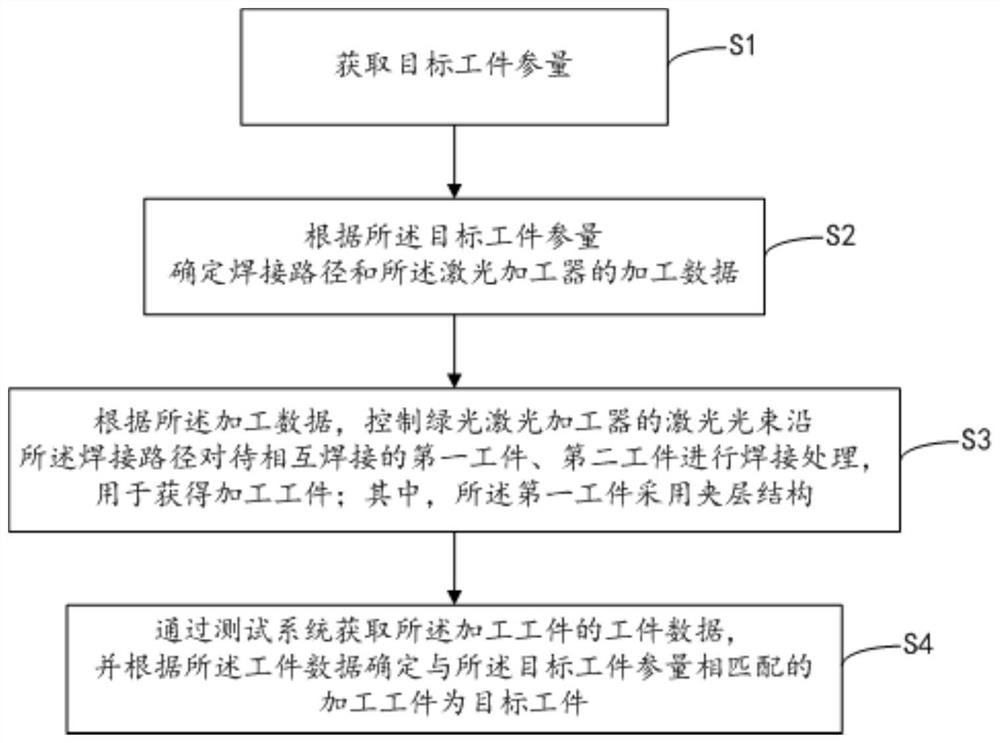

Laser welding method, laser processing equipment and sandwich structure workpiece

A laser processing and laser welding technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of unstable welding process and unsatisfactory welding effect, and achieve a wide welding range, better welding effect and stability. Best, optimize the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

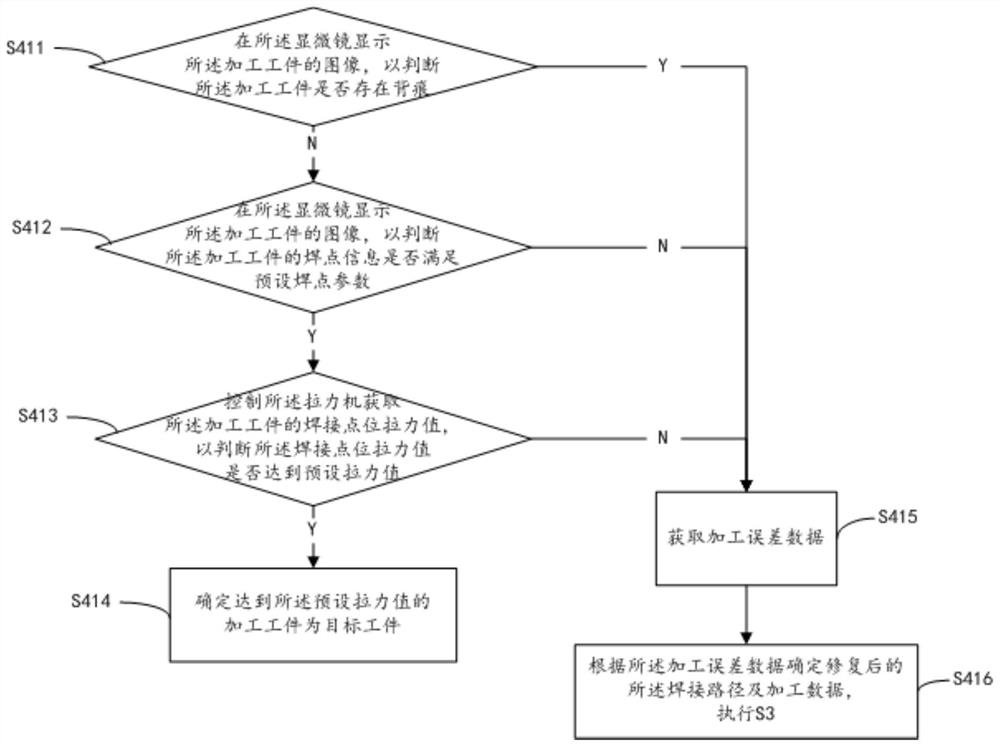

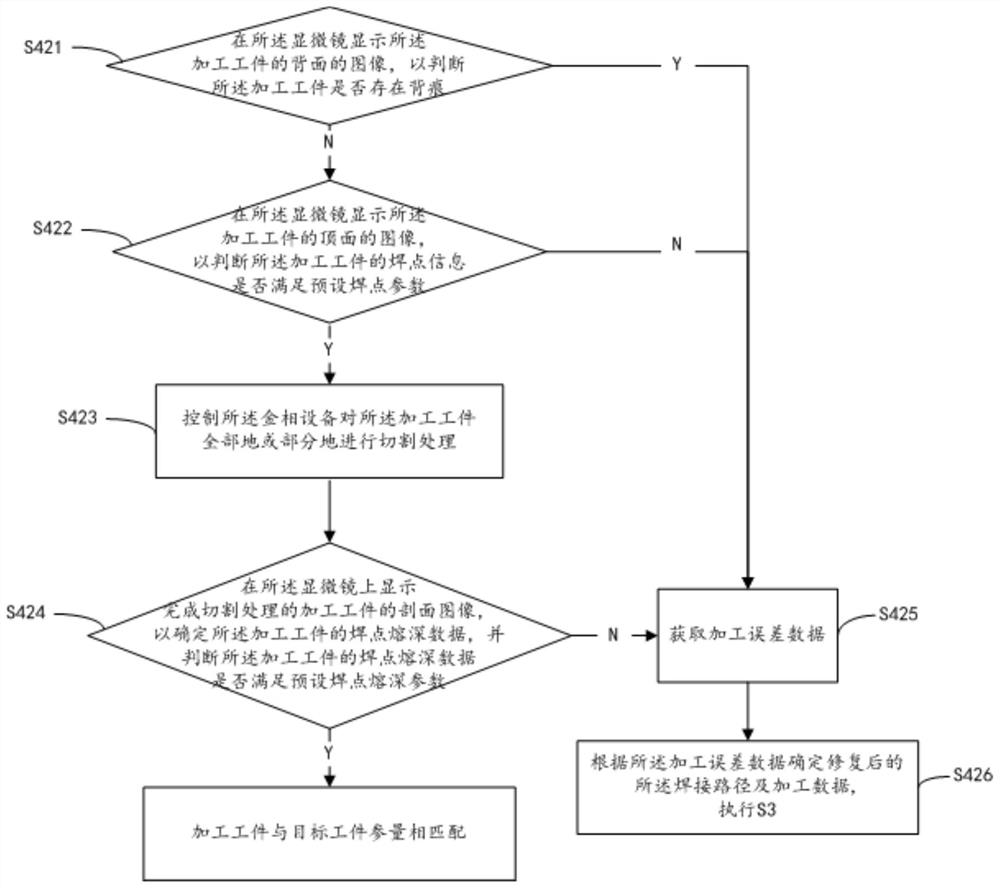

[0081] As one of the implementation examples of the present application, an image of the processed workpiece is displayed through a microscope, and the image includes images of a top surface and a back surface of the processed workpiece, and the image of the top surface of the processed workpiece is visually displayed through the microscope. Solder joint diameter, solder path and back marks on the back.

[0082] On the basis of the image displayed by the above microscope, the tensile force value of the welding point of the processed workpiece after the welding process is obtained by the tensile machine, so as to judge whether the processed workpiece is the target workpiece according to the obtained tensile force value of the welding point.

[0083] Based on this example, the S4 specifically includes the following steps:

[0084] S411. Display the image of the workpiece on the microscope to determine whether the workpiece has a back mark, if not, execute S412; if so, execute S4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com