Low-temperature liquid tank container barrel butt-joint tool and butt-joint welding method

A tank container, low temperature liquid technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of fast cooling speed, reduce production efficiency, welding quality impact, etc., to prevent welding defects, improve efficiency, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

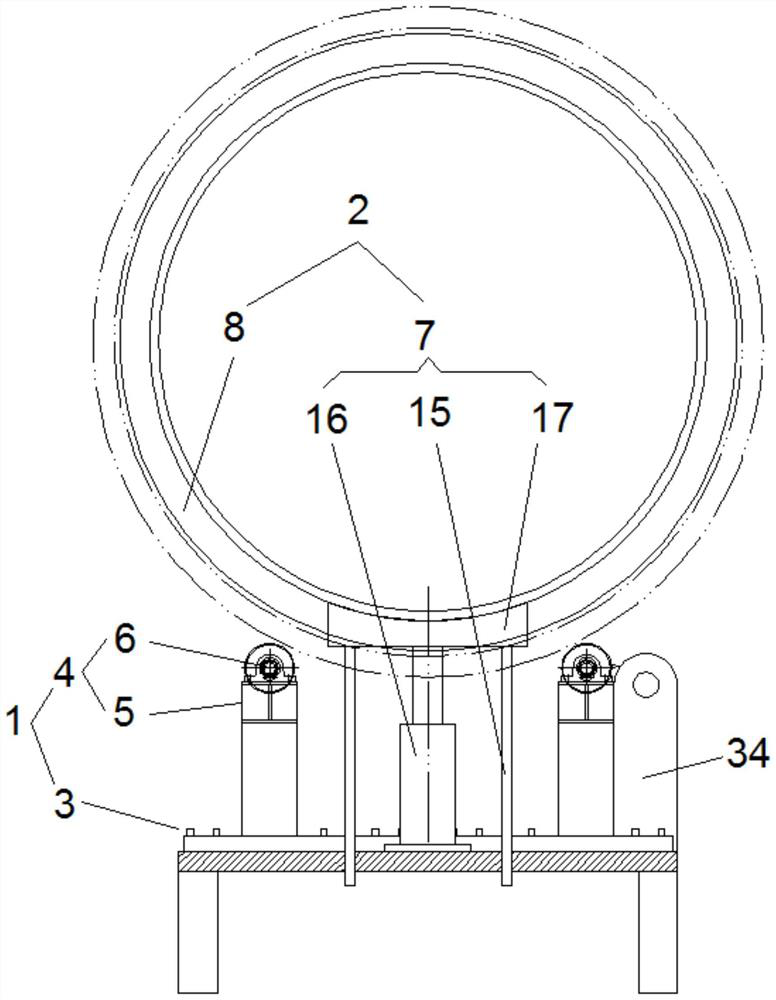

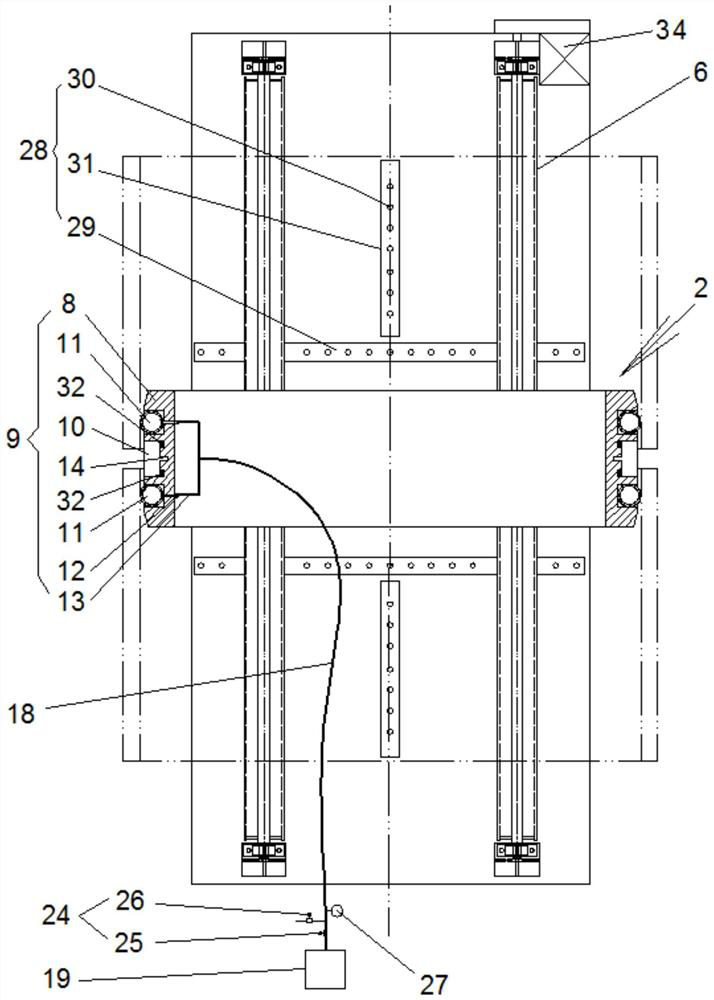

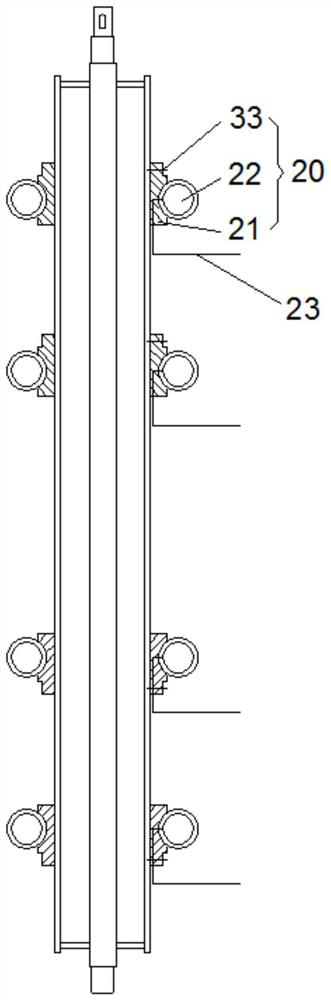

[0043] like Figures 1 to 4 Shown is an embodiment of a low-temperature liquid tank container barrel docking tool of the present invention, including a barrel positioning device 1 and a barrel mouth coaxial docking device 2, the barrel positioning device 1 includes a base 3, which is arranged on the A pair of cylinders at the upper left and right sides of the base 3 support rotating assemblies 4, and each cylinder supporting rotating assembly 4 includes a pair of bearing seats 5 that are respectively fixed at the upper and lower positions of the base 3, and are rotatably arranged on the A pair of axle rollers 6 on bearing seats 5; the barrel mouth coaxial docking device 2 includes a height-adjustable support seat 7 that is fixedly arranged on the base 3 and is located directly below the butting part of the barrel body, and is supported on the The rigid annular ring 8 on the height-adjustable support base 7, and the diameter step difference automatic compensation centering devi...

Embodiment 2

[0054] A butt welding method using the low temperature liquid tank container barrel butt joint tooling of Embodiment 1, comprising the following steps:

[0055] (1) Adjustment of the cylinder body positioning device: According to the length specifications of the pair of cylinder bodies to be docked, adjust the position of each flexible support assembly 20 on the outer circle of the shaft roller 6, so that the flexible support assembly 20 is adjusted to be able to stably support a the proper position of the cylinder;

[0056] (2) Installation of the coaxial docking device at the barrel mouth: hoist the rigid annular ring 8 with the automatic compensation centering device 9 for the diameter difference to the height-adjustable support base 7, so that the positioning insert 17 on the top of the telescopic rod of the electric push rod 16 is hoisted. Supported in the positioning slot 16 of the rigid annular ring 8; adjust the air pressure in the annular rubber elastic tire 11 to a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com